Forklift Seat Mounts

A technology for installing seats and seats, which is applied to vehicle seats, seat suspension devices, vehicle components, etc., can solve the problems of poor comfort and large vibration of forklift seats, so as to reduce vibration, improve work efficiency, and improve comfort. Effects of Sex and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

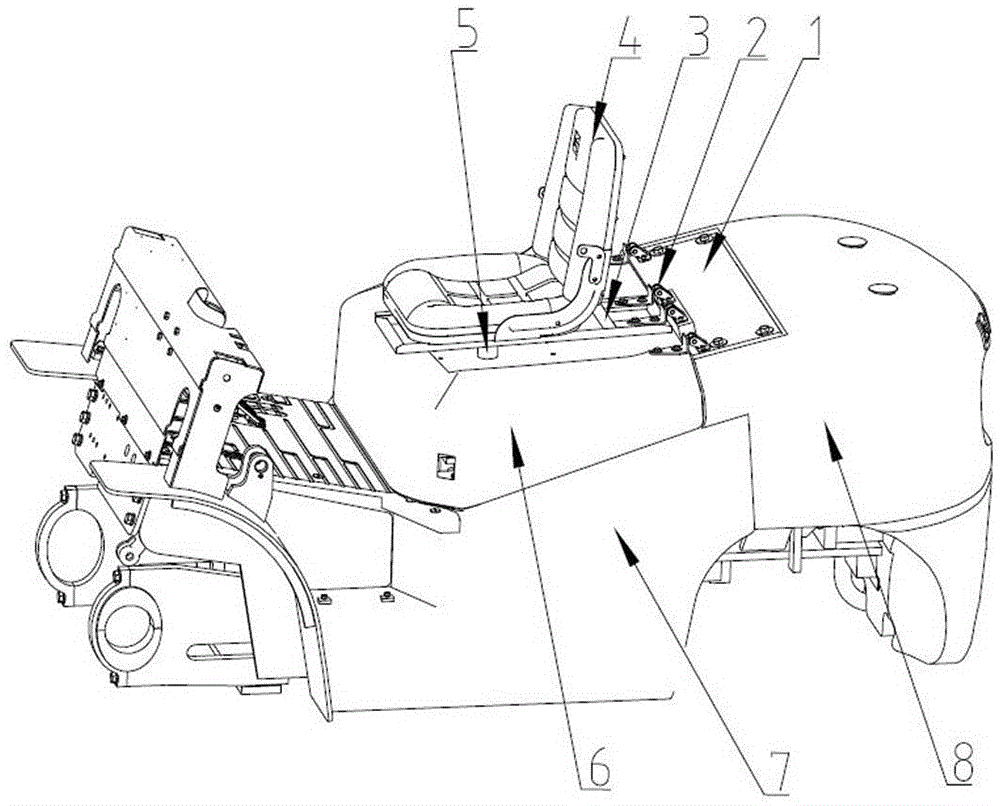

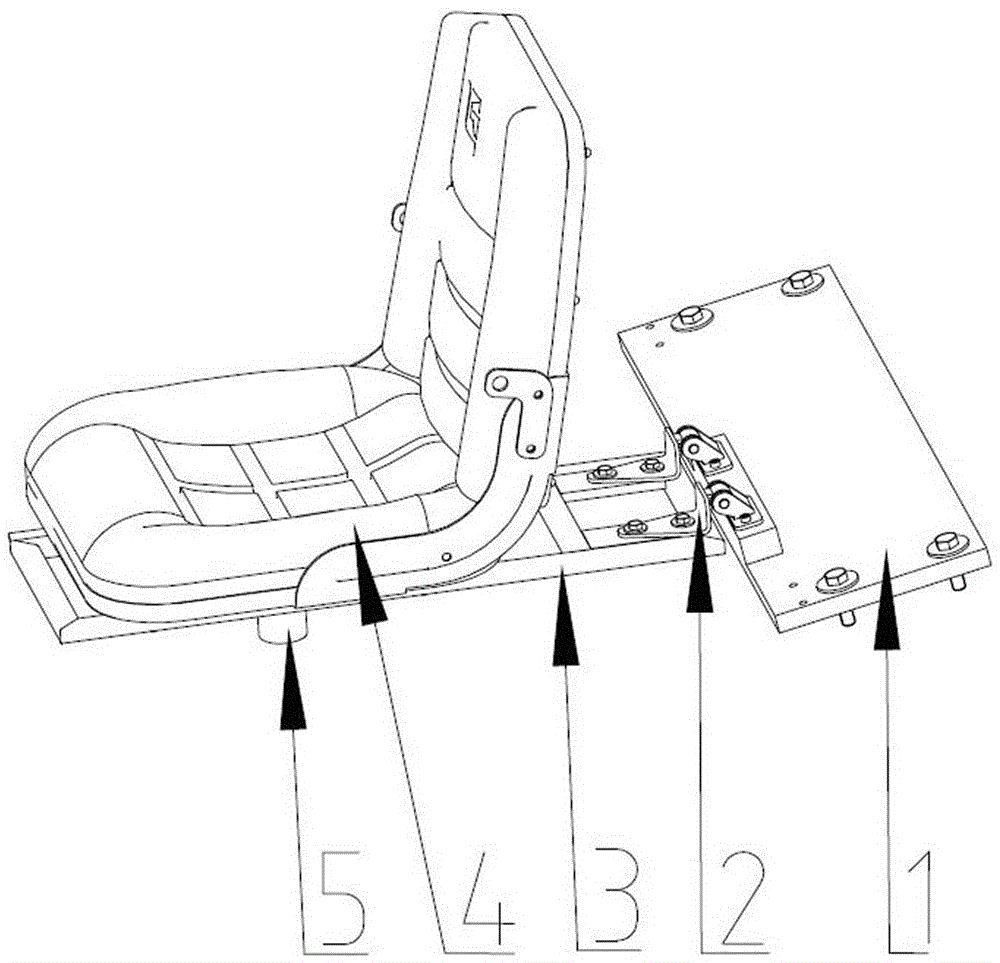

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

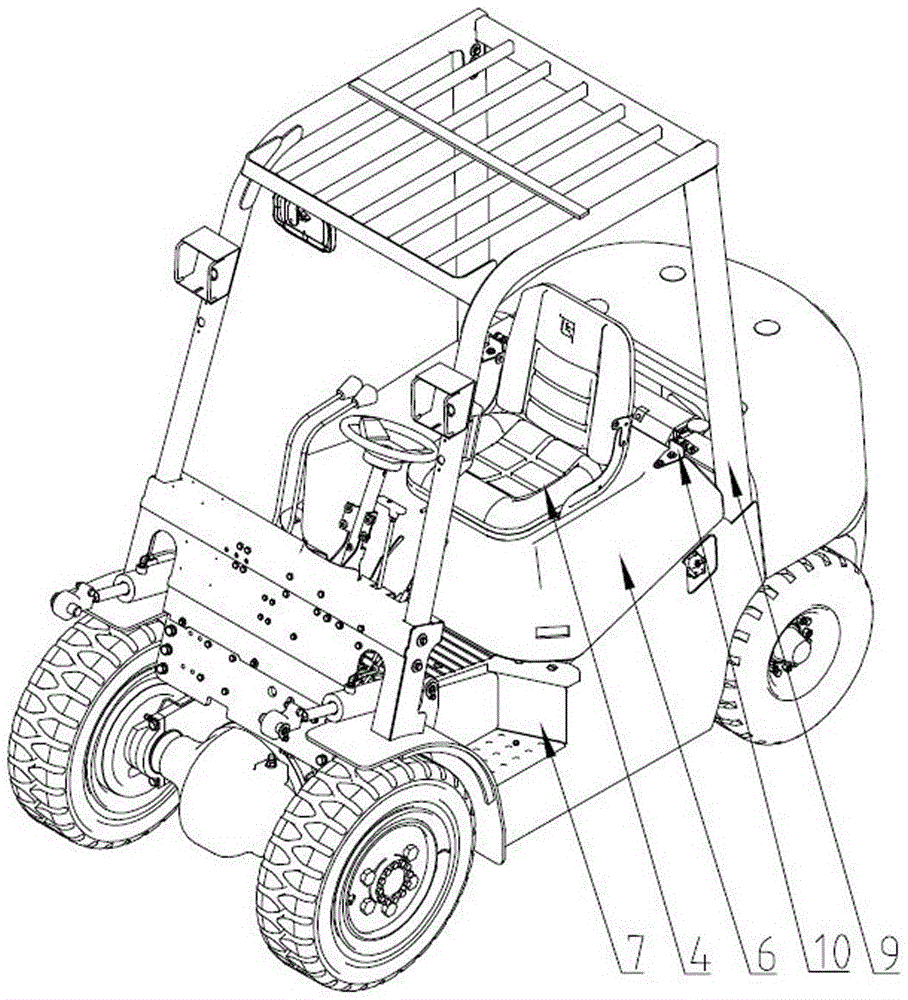

[0019] figure 1 It is a schematic diagram of the traditional forklift seat installation method; in the traditional forklift, the forklift seat 4 is directly installed on the engine cover 6, and the engine cover 6 is hinged with the roof guard 9 through the second hinge 10, and the roof guard 9 is rigid with the vehicle frame 7 connect. Since the small and medium tonnage forklift is a rigid suspension, the vibration of the engine can be directly transmitted to the frame 7, and the vibration of the frame 7 is relatively severe. This connection method allows the vibration to pass through the frame 7—the roof guard 9—the engine cover 6— The path of the seat 4 is easily transmitted to the bottom of the seat 4, and the driver feels very bad; and the design of the roof guard 9 and the engine cover 6 of many forklifts is unreasonable, resulting in the vibration mode being lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com