Four-wheel drive tractor with elastic suspension front axle

A four-wheel drive, elastic suspension technology, applied in the direction of elastic suspension, suspension, control device, etc., can solve the problems of poor ride comfort, complex shock absorption structure, reduced transportation capacity, etc., to enhance transportation capacity and increase off-road ability, the effect of reducing torque transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

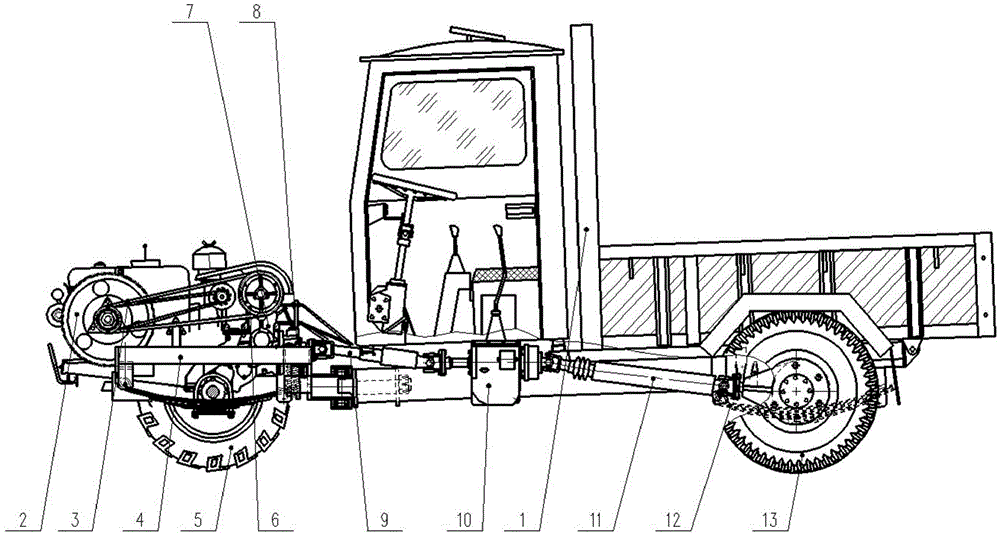

[0027] Such as figure 1 As shown, the present invention comprises a vehicle body 1 and an engine 2 installed on the front portion of the vehicle body 1, and a belt 3, a clutch 6, a front gearbox 7, a transfer case 8, a front transmission shaft 9, a rear gearbox 10, and a power transmission sequentially. Rear drive shaft 11, rear axle assembly 12, also comprise the rear tire 13 that is installed in vehicle body 1 rear portion and rear axle assembly 12 is connected, front gearbox 7 is provided with drive shaft 18, and front gearbox 7 passes drive shaft 18 Installed on the elastic suspension front axle 4, the elastic suspension front axle 4 is connected with the vehicle body 1 and the transfer case 8 respectively, and the drive shaft 18 is connected with the front tire 5.

[0028] In this embodiment, after loading heavy goods, the vehicle body 1 is pressed down, and the transfer case 8, the front gearbox 7, the engine 2, etc. are driven down together by the elastic suspension fro...

Embodiment 2

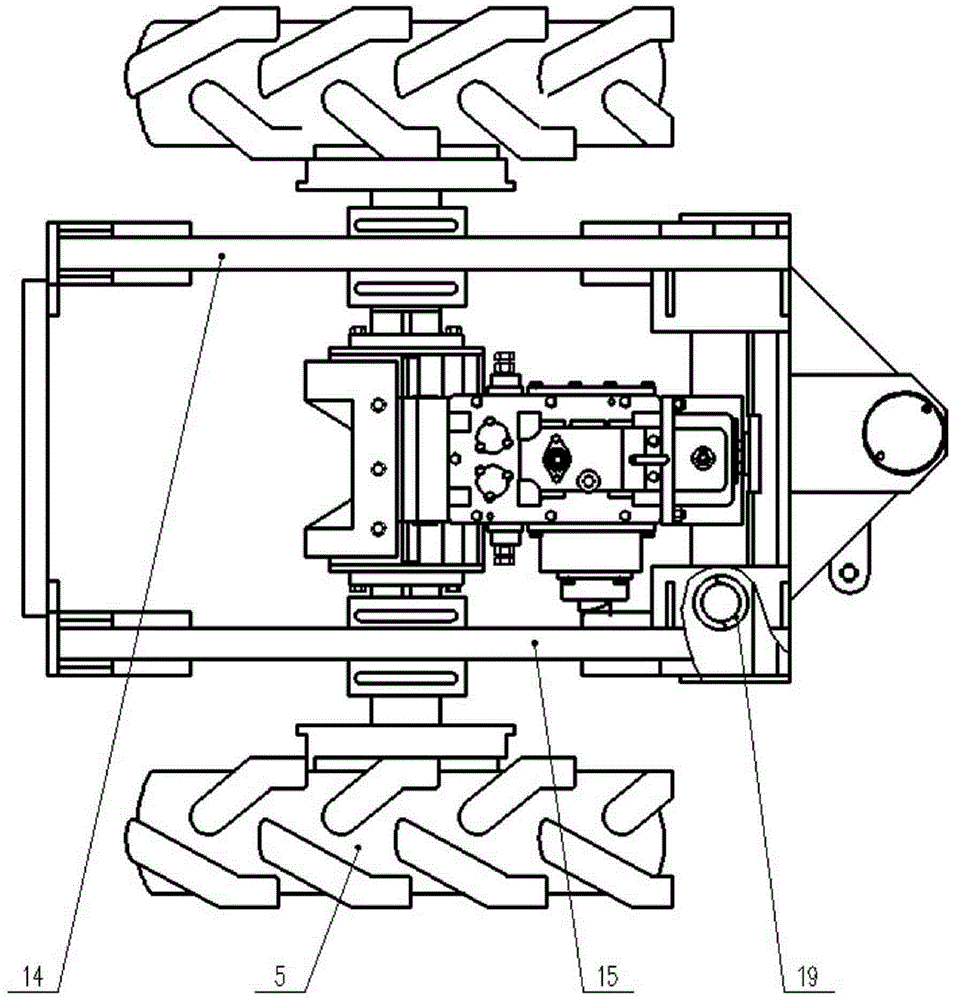

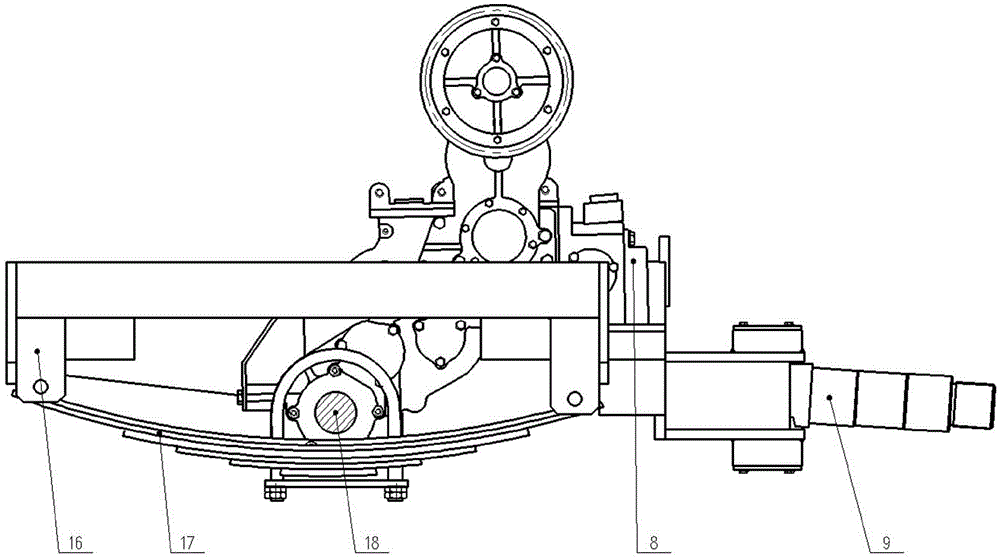

[0030] Such as figure 2 , image 3 As shown, the difference from Embodiment 1 is that the elastic suspension front axle 4 includes a left upper plate 14, a right upper plate 15, a vertical plate 16, and an elastic steel plate 17, and the two ends of the left upper plate 14 and the right upper plate 15 are connected into a rectangle by a horizontal plate frame, the front end and the rear end of the rectangular frame are connected with the elastic steel plate 17 by the riser 16, the middle part of the elastic steel plate 17 is connected with the drive shaft 18, and the rear end of the rectangular frame is connected with the vehicle body 1.

[0031] In this embodiment, after the heavy cargo is loaded, the body 1 is pressed down, and the elastic steel plate 17 is compressed by the rectangular frame, which drives the transfer case 8, the front gearbox 7, the engine 2, etc. to be pressed down together, thereby reducing the size of the body 1 and the front gearbox. The included ang...

Embodiment 3

[0033] Such as Figure 4 As shown, the difference from Embodiment 2 is that the rear end of the rectangular frame is connected with the support 20 through the spring 19 , the rear end of the rectangular frame is connected with the vehicle body 1 , and the spring support 20 is connected with the transfer case 8 .

[0034]In this embodiment, after loading heavy goods, the vehicle body 1 is pressed down, and the spring 19 is compressed by the rectangular frame, and the spring 19 squeezes the support 20, driving the transfer case 8, the front gearbox 7, the engine 2, etc. to be pressed down together, so that The body 1 and the front gearbox 7 keep parallel or the angle remains constant, so that the torque of the engine 2 can be fully exerted; when the speed of the vehicle is fast and the vibration of the engine 2 is huge, the compression of the spring 19 can reduce the shock and increase the ride comfort When encountering potholes on the road surface, the front tire 5 enters a pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com