A device for preventing longitudinal scratches of slider and cavity convex core in injection mold

An injection mold and slider technology, applied in the field of protective devices, can solve the problems of poor products, low production efficiency, and increased overall product cost, and achieve the effects of reducing overall cost, prolonging service life, and improving production and operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

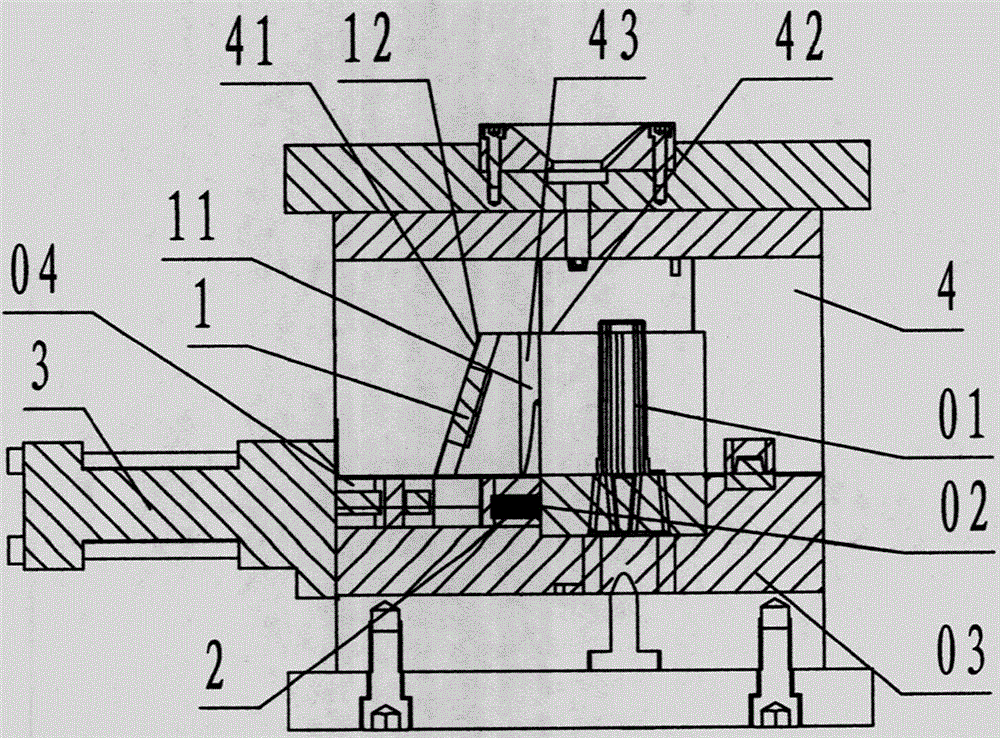

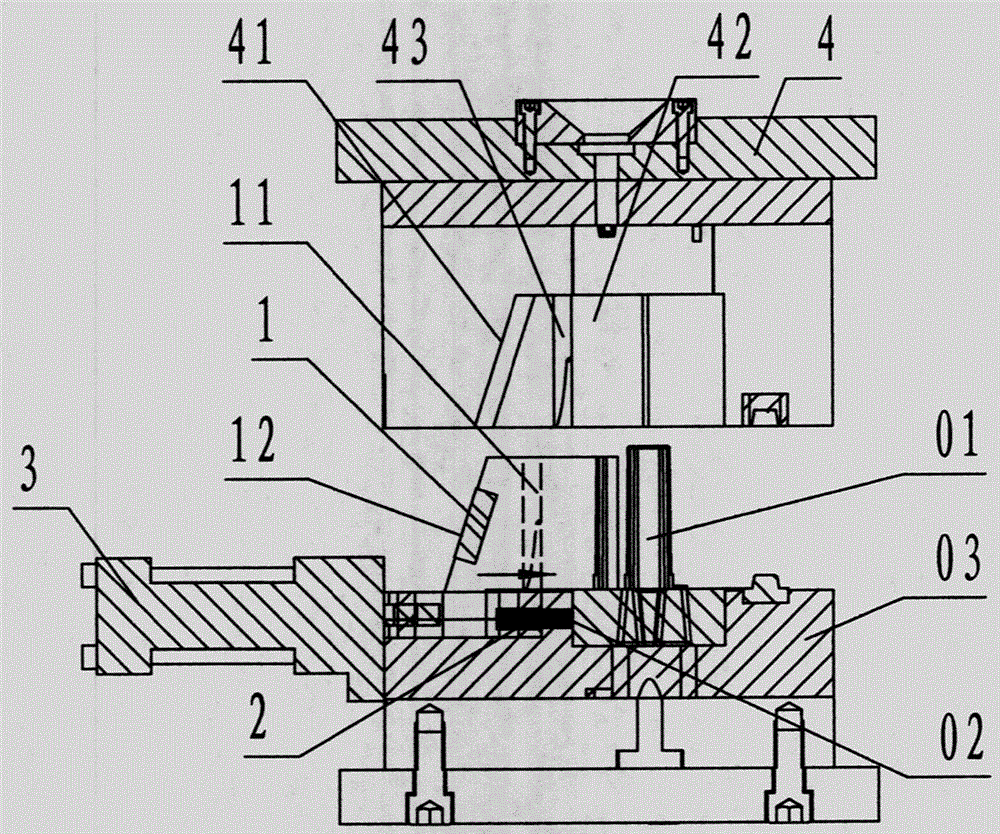

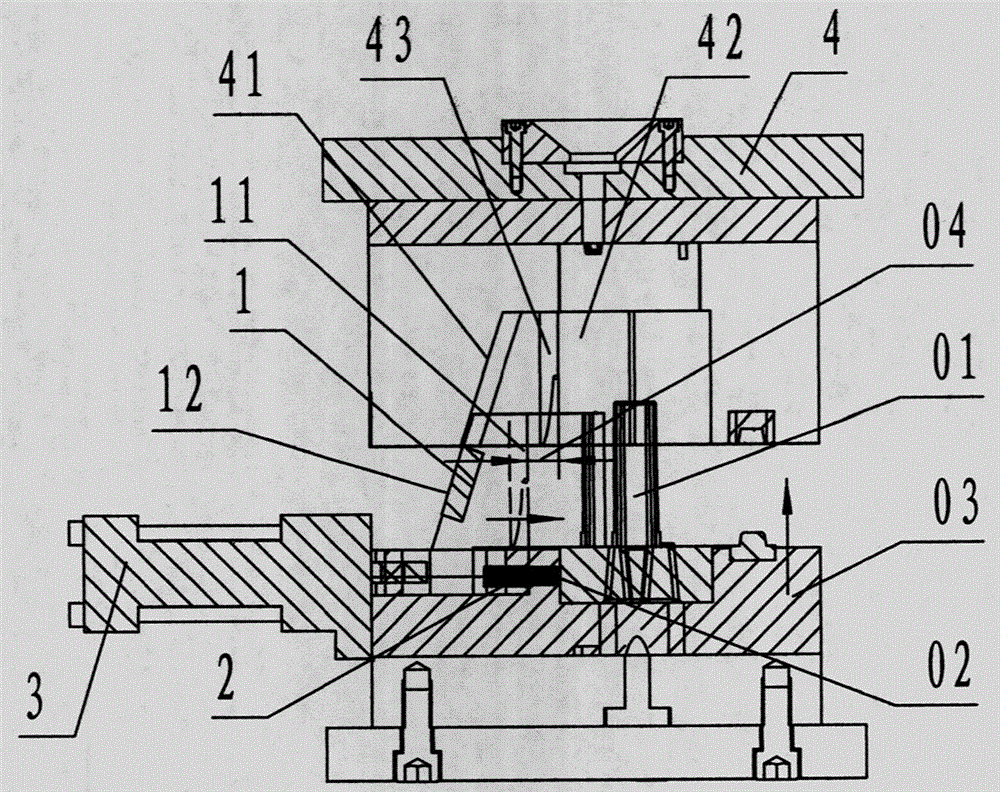

[0020] refer to Figure 1 ~ Figure 3 , a device for preventing longitudinal scratching of the slider and the convex core of the injection mold of the present invention, comprising a horizontal slider 1, a spring 2, an oil cylinder 3, and a fixed mold 4, wherein: the horizontal slider 1 is the upper part of the right side surface A steel block member with a profile that matches the product’s profile. The left side of the horizontal slider 1 is provided with a slope that is inclined from top to bottom and left, which is called a driven slope 12. The shape of the horizontal slider 1 When the mold is closed to form a mold cavity, there is a parting wall that is sealed and collided with the convex core of the cavity, which is called the block partition wall 11; the lower part of the right side of the transverse slider 1 is provided with a blind hole for placing the spring 2, which is called spring hole;

[0021] The spring 2 is a cylindrical helical compression spring;

[0022] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com