Pipe removing machine and method for manufacturing artificial sheath by using pipe removing machine

A wrapping and tube machine technology, applied in the application, processing of meat, sausage casings, etc., can solve the problems of stop of pleating process, interruption of winding shaft, economic loss, etc., to optimize output and eliminate human error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment is described below with reference to the above-mentioned drawings, but this does not limit or reduce the scope of protection of the present invention.

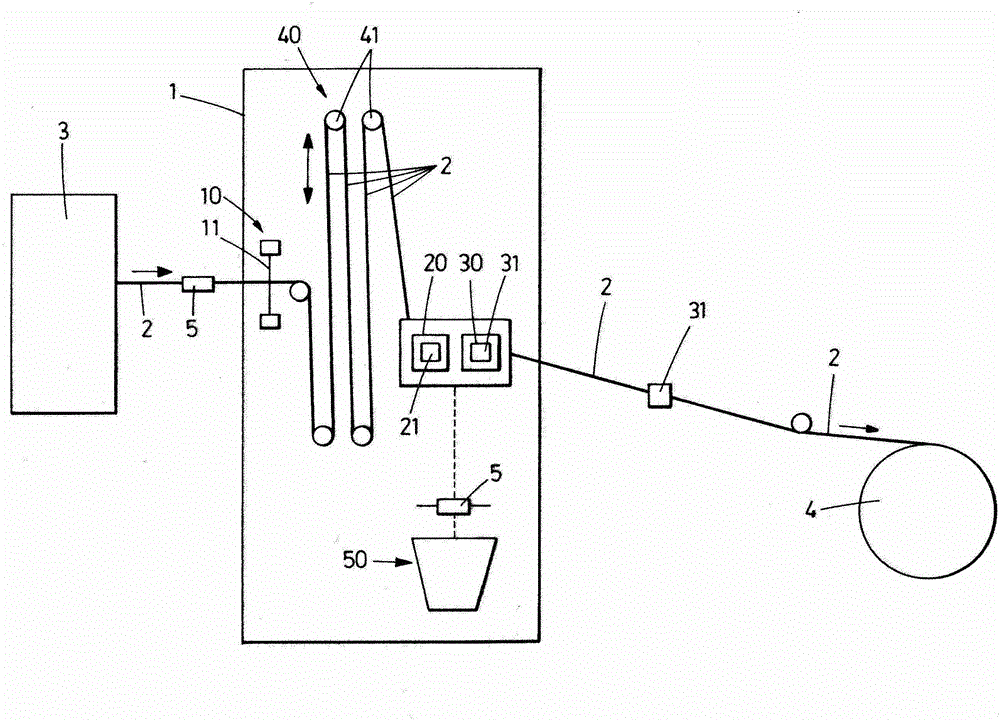

[0031] figure 1 Shows a basic diagram of the production line for the production of manual sheathing 2 combined with the pipe removing machine 1 of the present invention. In this example, the pipe removing machine is located between the dryer 3 for drying the sheath 2 and the coil Between the winding shafts 4 of the wrapper. More specifically, according to this example, the pipe removing machine 1 includes:

[0032] -A detection device 10 for detecting the arrival of the tube 5 contained in the sheath 2 and including a photocell 11,

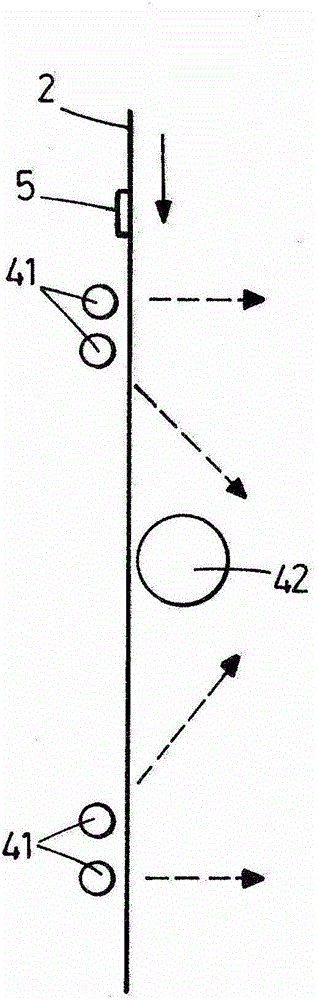

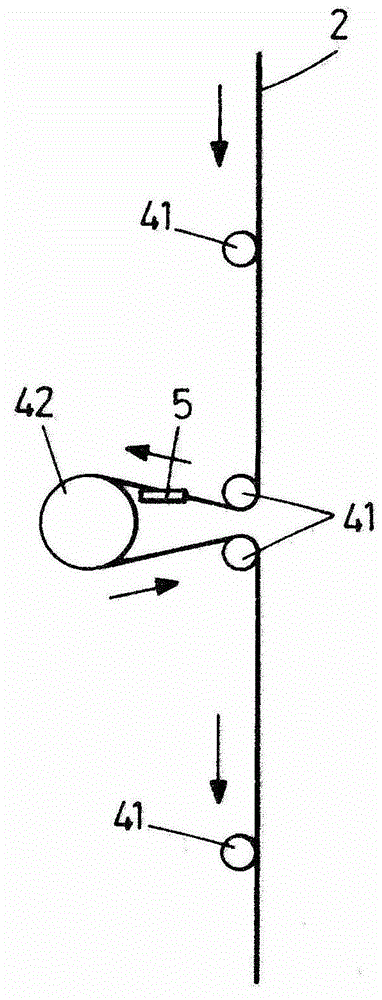

[0033] -Approaching or approaching device 50 for driving the part to be cut of the sheath 2 towards the cutting device, and is included in Figure 2A-2D The extracting roller 51 and the main roller 52 depicted in

[0034] -A cutting device 20 for cutting the part of the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com