Rectangular part stock layout method based on grouping technology

A technology of rectangular parts and technology, which is applied in the field of rectangular part layout based on group technology, can solve the problems of slow search speed and decline in layout quality, and achieve the effect of speeding up the solution speed, reducing the retrieval time and improving the solution quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

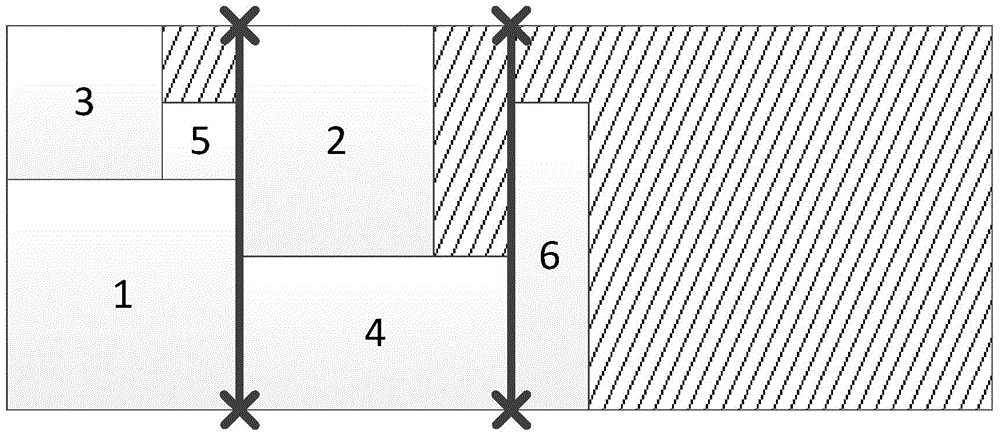

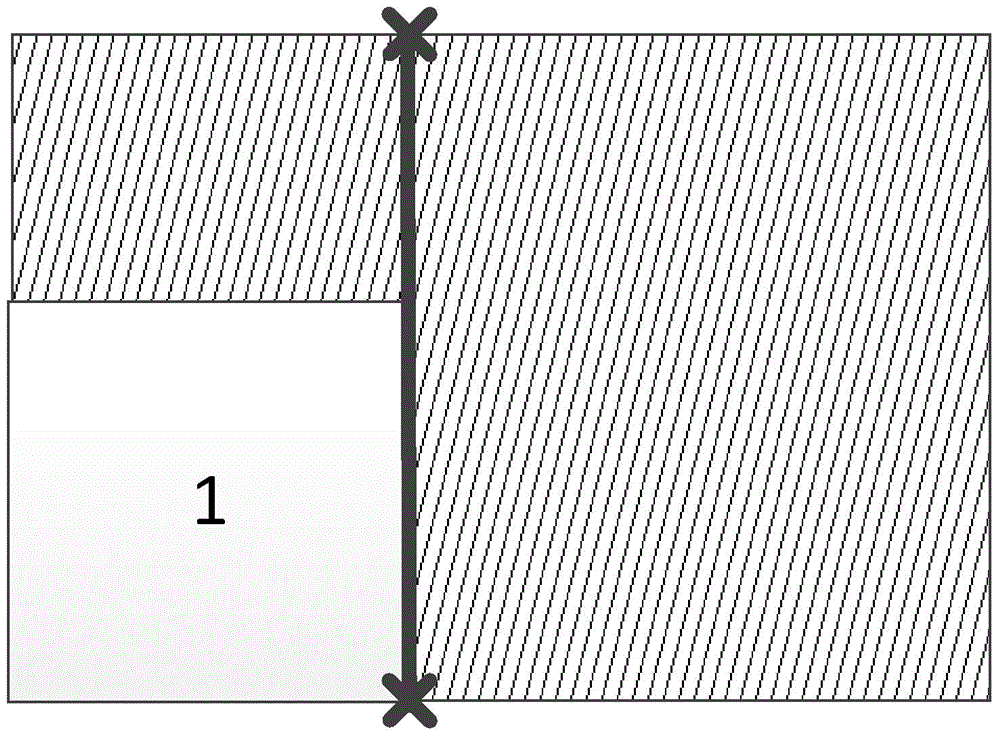

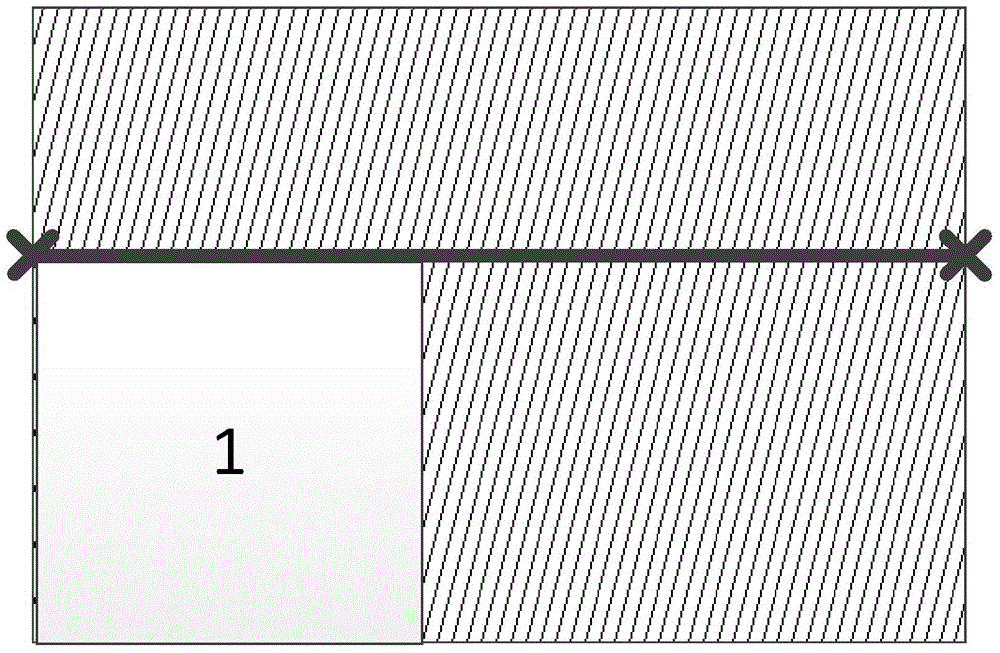

[0052] (1) Reference Figure 5 Specifically illustrate the generation method of the combination of the present invention:

[0053] The method includes the following steps:

[0054] ① Add all rectangular pieces to the list gList, and then rotate all non-square rectangular pieces by 90 degrees, and add them to the list gList;

[0055] ② Record the length of the list at this time and assign it to the variable length;

[0056] ③ Define the initial position pointer iPoint = 1; the end position pointer ePoint = length;

[0057] ④ From the 0th position of the list gList to the end of the (length-1) position, select the element r (rectangular piece) in sequence.

[0058] ⑤ From the iPoint position of the list GList to the end of the ePoint position, select the non-frozen element g (rectangular piece or combined rectangular piece) in turn, and judge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com