The Constant Force Feeding Device of the Subpackaged Shell

A sub-packed, artillery shell technology, applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of constant sending elastic force, affecting shooting effect, inconsistent projectile sending position, etc., to achieve convenient operation and structure. Simple, mass-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

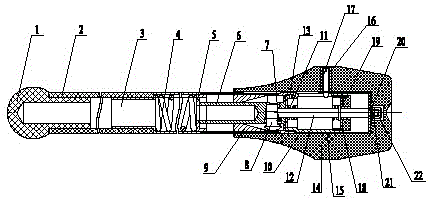

[0032] This embodiment is a constant force delivery device for sub-package shells, refer to figure 1 ,it includes:

[0033] (1) Force application mechanism

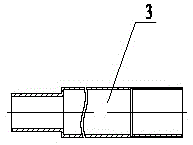

[0034] The force application mechanism is used for external personnel to directly apply thrust. The force application mechanism in this embodiment includes a force application head 1 and a hollow rod 2. For the convenience of operation, the force application head 1 in this embodiment is as follows: figure 1 The arrangement shown is in the form of a ball head, and the force application head 1 is provided with an extension rod, which is placed in the cavity of the hollow rod 2 and is interference-fitted with the inner cavity of the hollow rod 2 .

[0035] (2) elastic mechanism

[0036] The elastic force mechanism generates compressed elastic force under the action of external personnel's thrust, and this embodiment utilizes the compressed elastic force to push the projectile into place.

[0037] Such as figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com