Integrated formwork and its construction technology for tunnel inverted arch backfill construction

A formwork and tunnel technology, which is applied in the field of integrated formwork and construction technology for tunnel inverted arch backfill construction, can solve the problems of increased workload and construction cost, easy deviation, etc., to increase workload and construction cost, and save equipment The effect of cost and convenience of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

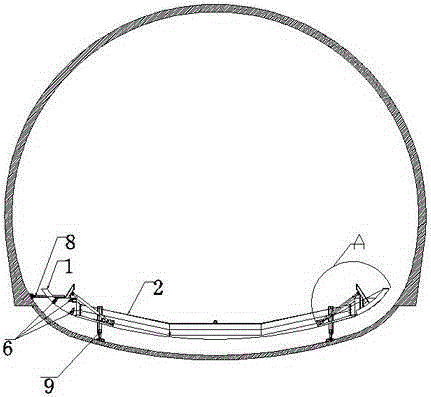

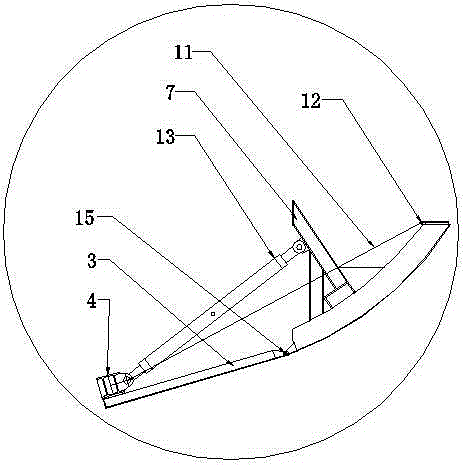

[0047] like figure 1 - Shown in -4, a kind of integrated formwork for tunnel inverted arch backfill construction, including two groups of side wall formwork 1, an end beam 2, two groups of overturned formwork 3, two formwork through beams 4, lateral support adjustment mechanism, The vertical support adjustment mechanism and the turning mechanism, the side wall formwork 1 and the turning formwork 3 are symmetrically arranged on both sides of the end beam 2, the side wall formwork 1 and the end beam 2 are rigidly connected, the side wall formwork 1 and the turning formwork 3 are hinged, and the formwork can be passed through The rotating shaft 15 is hinged, and the formwork beam 4 is rigidly connected with the overturned formwork 3; one end of the side wall formwork 1 is provided with a supporting walking mechanism for lapping in the side ditch 5 formed by the lining, and the other end is provided with a horizontal support adjustment mechanism for vertical support. The adjustmen...

Embodiment 2

[0064] The present invention is composed of two groups of left-right symmetrical side wall formworks, one side wall formwork end beam, two sets of overturned formworks, eight support jacks, two formwork through beams, and four 3t overturned gourds.

[0065] There are four sets of limit brackets and four gourd hooks in the middle of the side wall formwork; there are jack ears on the limit bracket; there are three rollers at one end of the side wall formwork, which can be stretched and retracted through the screw; the other end is provided with two horizontal The support and the connection seat connected with the end beam; the side wall formwork is also provided with a hinge ear hinged with the flip formwork.

[0066] Both sides of the end beam are provided with connection seats connected with the side wall formwork, and two vertical support jacks are provided below. There is a hook on the top.

[0067] The upper part of the overturned formwork is provided with a hinge ear whic...

Embodiment 3

[0075] like Figure 5 Shown, the A direction on the left is the inverted arch and the backfill completed part to indicate the central drainage ditch 19, the inverted arch backfill layer 20, the side ditch 5, and the side wall 21, and the B direction on the right side is in the construction state for adopting the present invention.

[0076] like Image 6 As shown, the present invention changes the reserved opening of the seepage pipe 14 to be placed horizontally, which is not easy to be blocked, and is easy to clean, and there is always a side ditch for guide rails and positioning references in the inverted arch and backfilling.

[0077] like Figure 7 As shown, the state of prior art inverted arch and backfill completion state seepage pipe 14 reserved opening has a bend, the reserved opening of the seepage pipe is easy to block, inconvenient to clean, and there is no side ditch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com