Beam column and supporting leg of anti-electrostatic floor support and connecting structure of beam columns and supporting legs

An anti-static floor and connection structure technology, applied in the fields of outriggers and their connection structures, and beams, can solve problems such as deformation, instability, and uneven access floors, and achieve unevenness, easy level adjustment, and easy and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

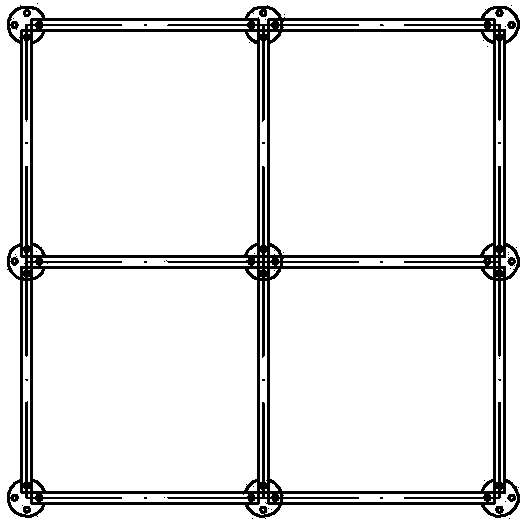

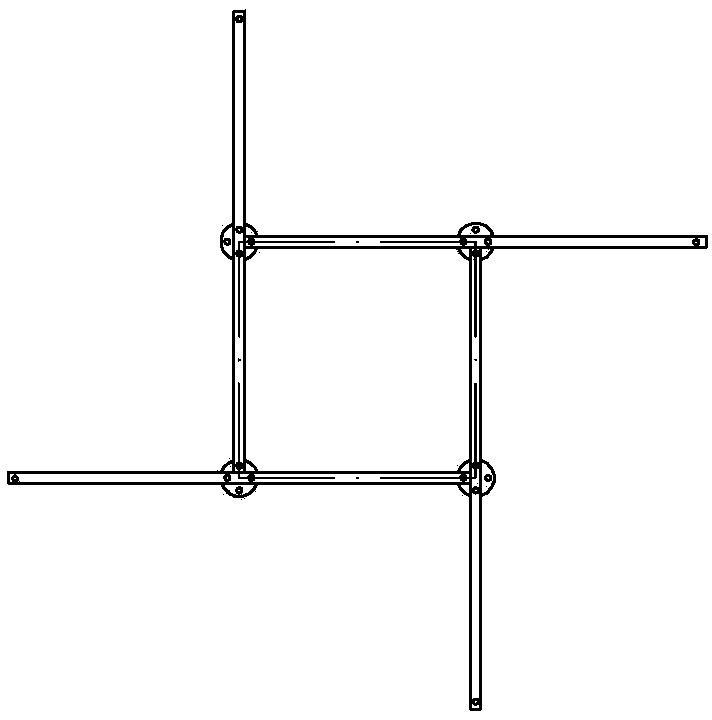

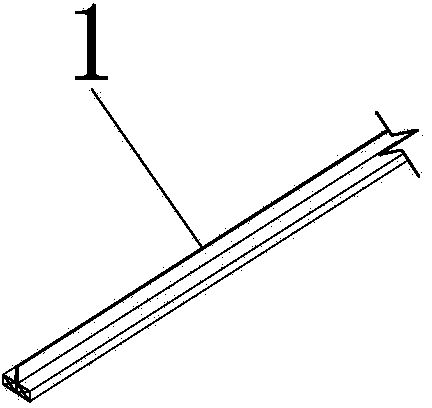

[0052] like Figure 3 to Figure 11 As shown, the girder of an anti-static floor support provided by the present invention is the main girder 1, and the length of the main girder 1 is greater than or equal to 1200mm.

[0053] Since this embodiment adopts the main girder, the length of the main girder is greater than or equal to 1200mm. Therefore, multiple main girders can be placed parallel to each other, or multiple main girders can be divided into two parts. There are several groups, the main beams of each group are connected in series through the main beam connectors to form a main beam string, and several main beam strings are placed parallel to each other. When the legs are erected, the legs at both ends of the main beam are first adjusted so that the main beam is in a horizontal position, and then the other legs below the main beam can be easily adjusted. Likewise, the other main girders can be adjusted to a horizontal position, and all the main girders are located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com