Immersion plate-type membrane bioreactor for improving membrane pollution control and wastewater treatment method using same

A bioreactor, pollution control technology, applied in sustainable biological treatment, anaerobic digestion treatment, aerobic process treatment and other directions, can solve the problems of low energy utilization, poor physical control technology effect, etc., to improve the critical flux , the effect of promoting renewal and slowing down the rate of formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The sewage treated in the following examples is printing and dyeing wastewater, and other unspecified parts involved in the present invention are prior art.

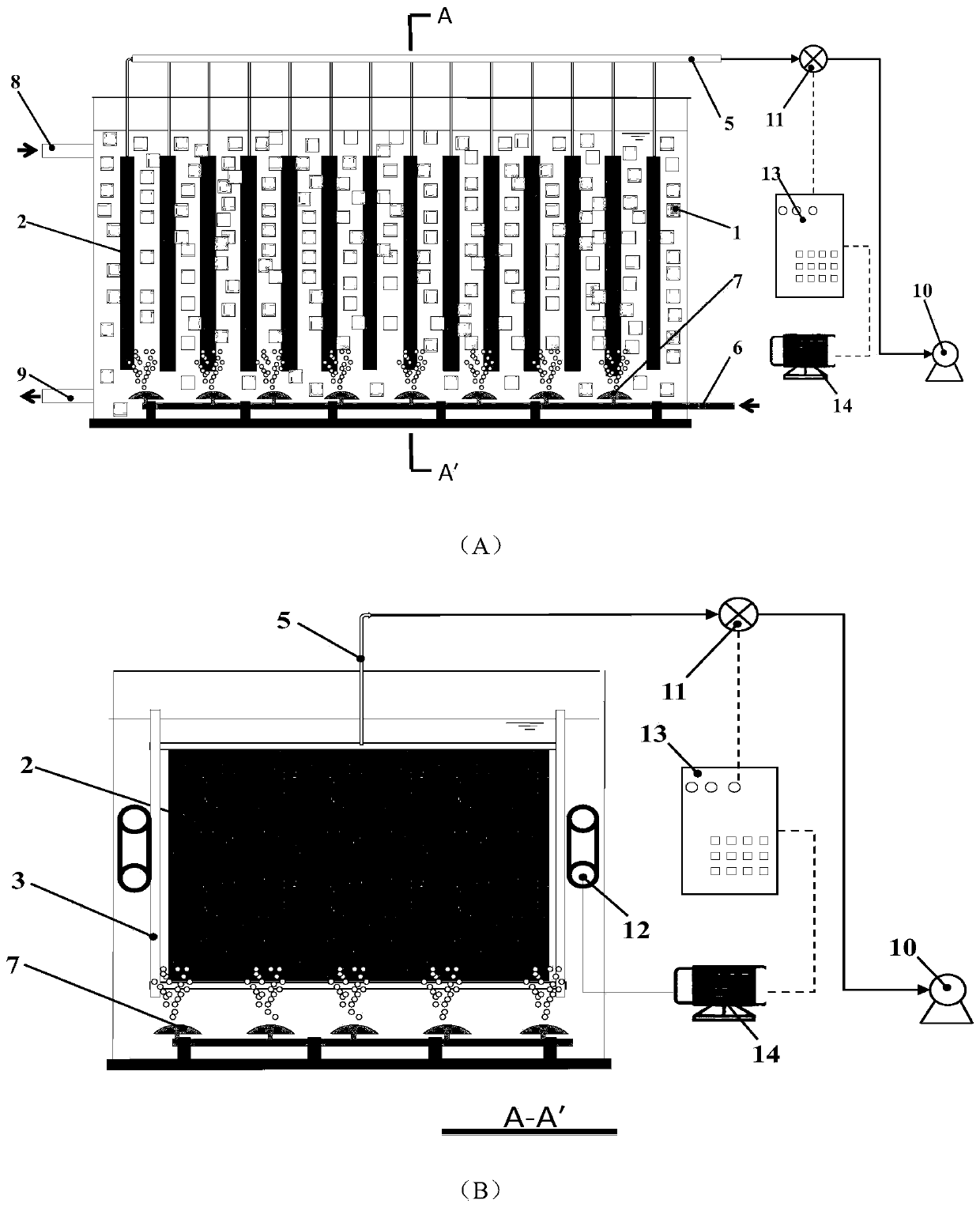

[0054] (1) As attached figure 1 As shown, in the submerged plate membrane sewage biological treatment reactor, 14 plate membrane modules 2 are fixed on the reactor frame 3 to form a whole and move synchronously. Several biofilm carriers 1 are suspended and distributed on both sides of the plate-type membrane element 2, forming a plate-type membrane bioreactor for sewage treatment composed of suspended sludge and biofilm. The vertical distance between adjacent plate-type membrane modules 2 is 1.5 times the maximum length of a single biofilm carrier 1 . A reciprocating drive device 12 is arranged on both sides of the reactor frame 3 and is connected with the reactor through the reciprocating drive device 12 . The total filling volume of the soft biofilm carrier 1 suspended in the reactor is 50% of the effective vo...

Embodiment 2

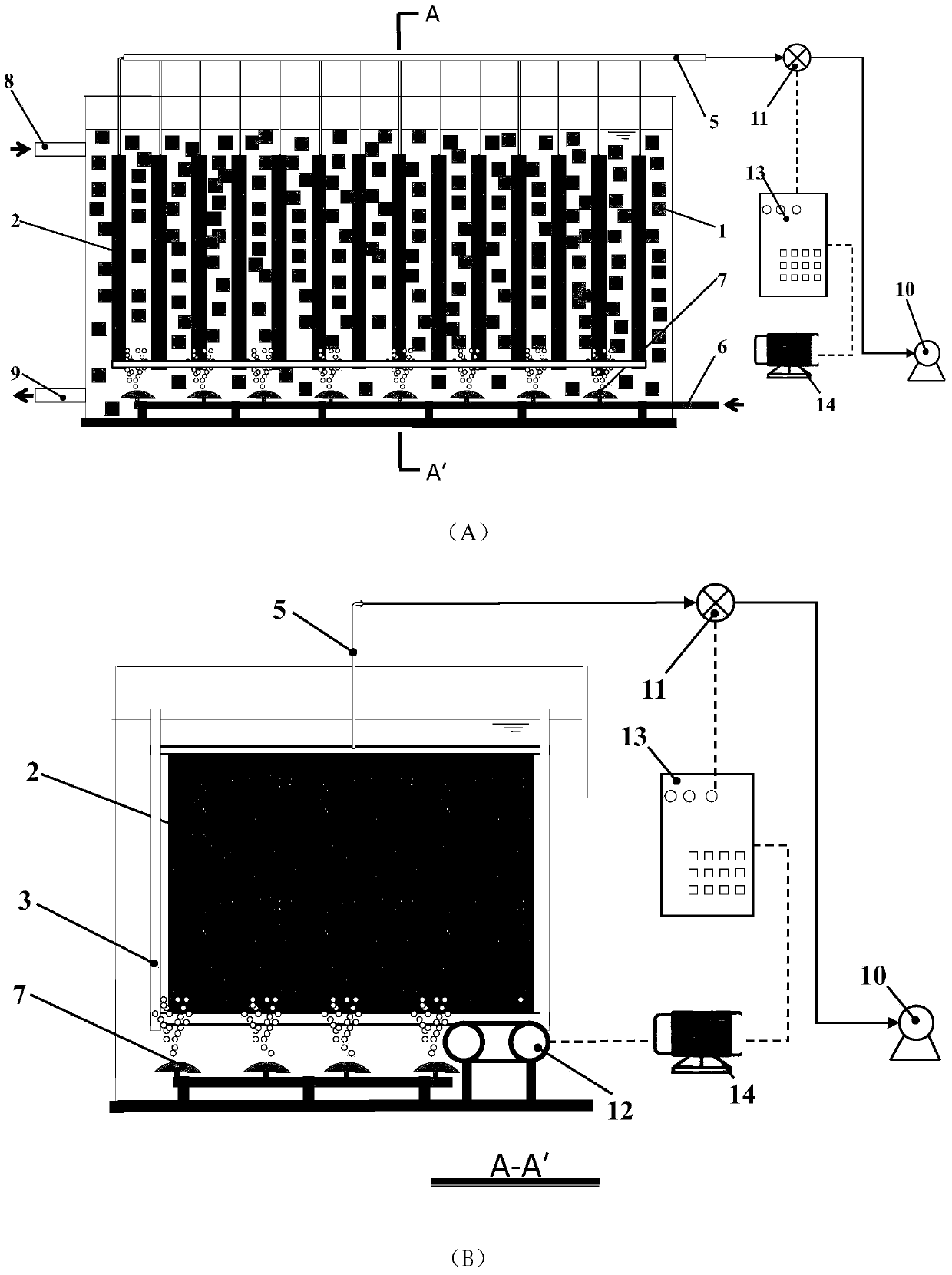

[0060] Compared with embodiment 1, as attached figure 2 As shown, the difference is that the reciprocating transmission device 12 is arranged at the bottom of the reactor frame 3, driven by the motor 14, the entire reactor frame 3 reciprocates below the liquid surface in a horizontal direction parallel to the plate membrane module 2. Set the initial transmembrane pressure difference to 5kPa. When the transmembrane pressure difference is less than 10kPa, the reciprocating frequency of the plate membrane is 5 times / s, and the amplitude is 0.2 times the width of the plate membrane element 2. The biofilm carrier 1 is suspended in the Clean the surface of the plate membrane at a relatively low speed in the device; when the transmembrane pressure difference is 10-20kPa, set the reciprocating frequency of the plate membrane to 5 times / s, and the amplitude is 0.3 times the width of the plate membrane element 2; when the transmembrane When the pressure difference is 20-30kPa, set the ...

Embodiment 3

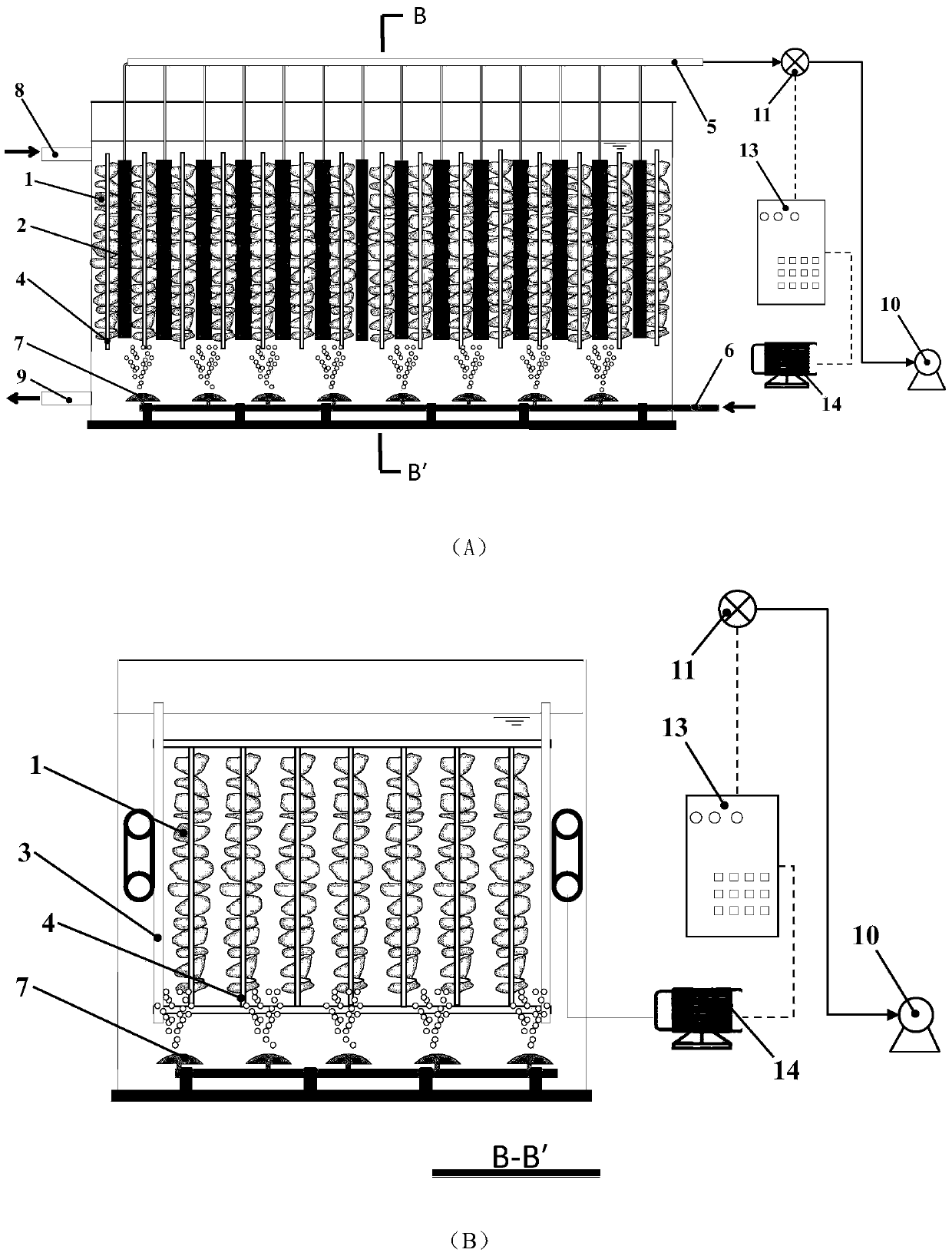

[0063] (1) As attached image 3 As shown, in the submerged plate membrane sewage biological treatment reactor, several biofilm carrier packing frames 4 are evenly fixed on the reactor frame 3, forming a whole and moving together. There are several biofilm carriers 1 used for biofilm growth in the biofilm carrier packing frame 4, and the biofilm carrier packing frames 4 are arranged on both sides of the plate membrane element 2 to form a sewage treatment plate membrane composed of suspended sludge and biofilm In the bioreactor, the total filling volume of the biofilm carrier 1 is 50% of the effective volume of the plate membrane bioreactor, and the vertical distance between adjacent plate membrane elements 2 is slightly smaller than the thickness of the filler frame after a single biofilm carrier 1 is filled. The membrane carrier packing frame is plug-in type, which can be easily removed or moved in, and is convenient for the replacement of the biofilm carrier.

[0064]A recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com