Electronic packing box stacking structure and method

A packing box and stacking technology, which is applied in the stacking structure and stacking field of electronic packing boxes, can solve problems such as inconvenient use, and achieve the effect of saving utilization rate and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing:

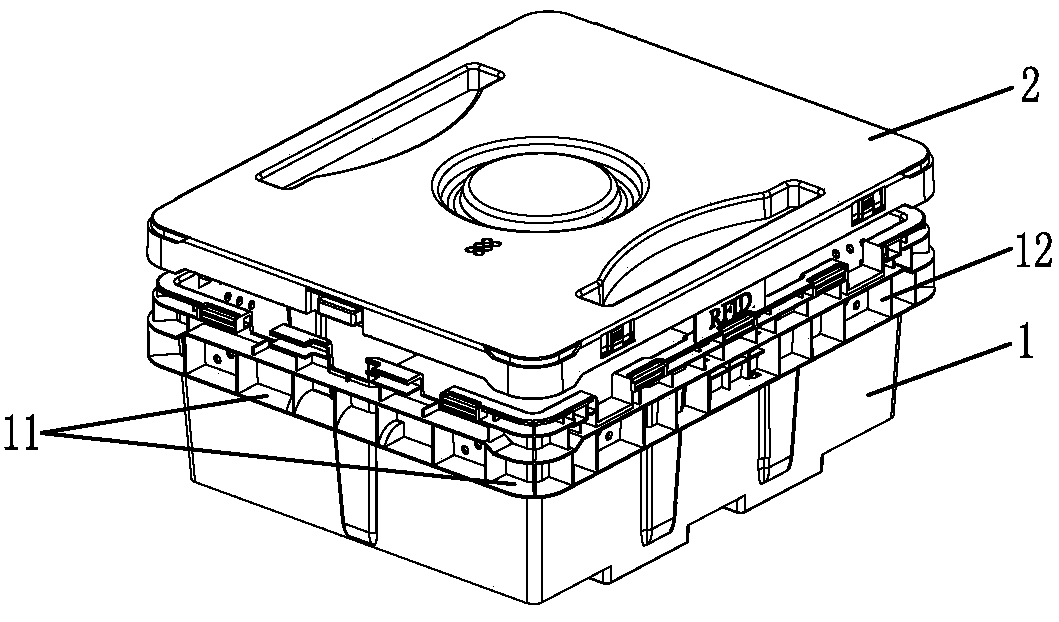

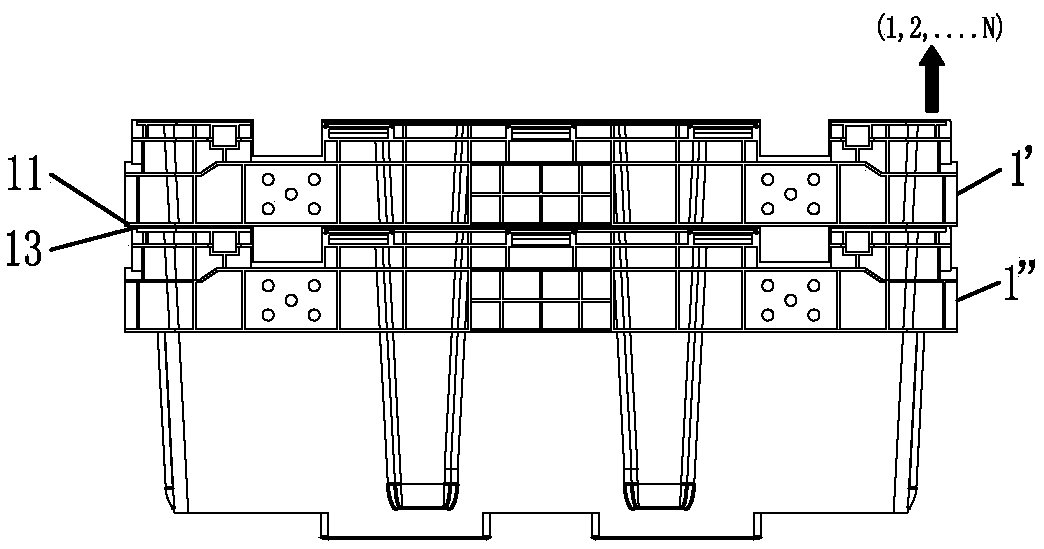

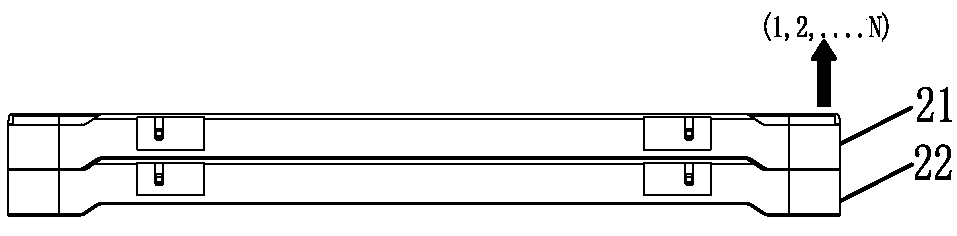

[0021] figure 1 , figure 2 Embodiments of the stacking structure and stacking method of the box body and the box body of the electronic packaging box of the present invention are shown.

[0022] see figure 1 As shown, the top side wall of the box body 1 is protruded in the horizontal direction with an annular anti-collision stock edge 11 protruding from the side of the box body 1, and formed between the anti-collision stock edge 11 and the four edges of the box body 1 opening. Grid-like ribs 12.

[0023] see figure 2 As shown, the movable socket between the upper box 1 and the lower box 1 is through the top box 1 , The anti-collision stock edge 11 is in active contact with the bottom box body 1 ,, The mouth end 13 forms the upper box body 1 , with lower box 1 ,, overlapping between.

[0024] In this embodiment, the palletizing method of the electronic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com