Wheel assembly, motor wheel assembly and scooter

A wheel assembly and motor wheel technology, which is applied to motorcycles, motor vehicles, bicycles, etc., can solve problems such as poor heat dissipation and rigid design of wheel assemblies, and achieve the effect of easy installation, disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings:

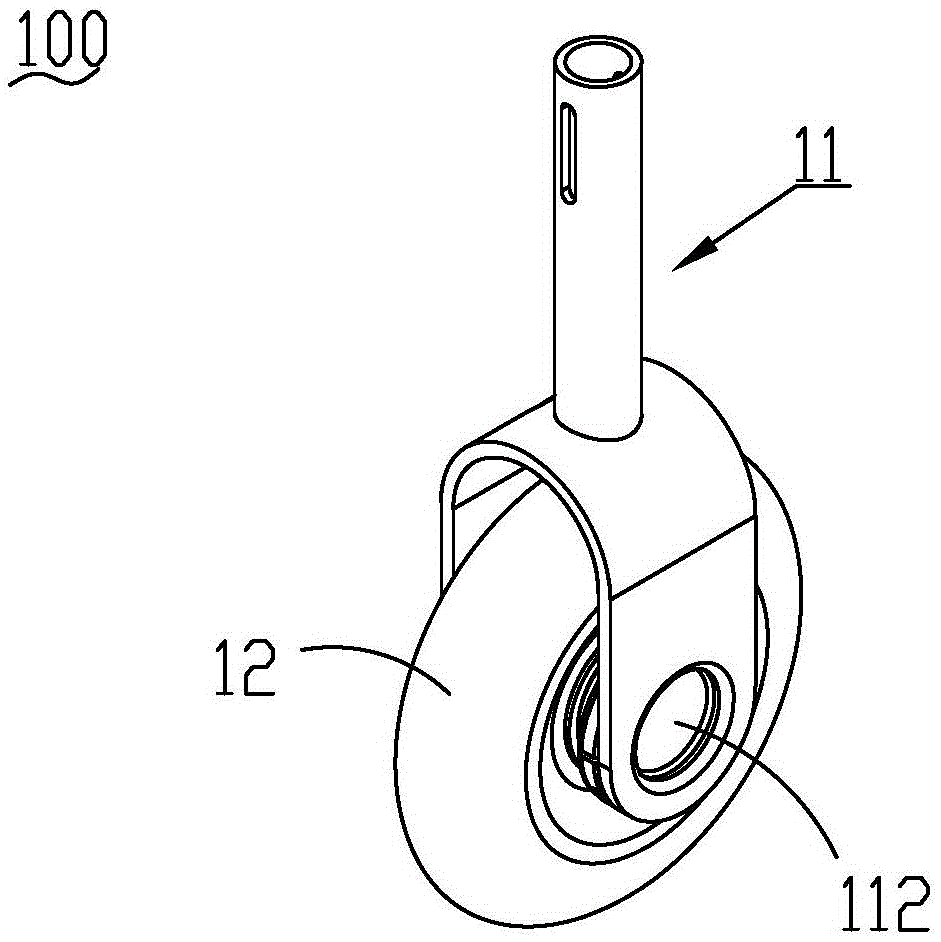

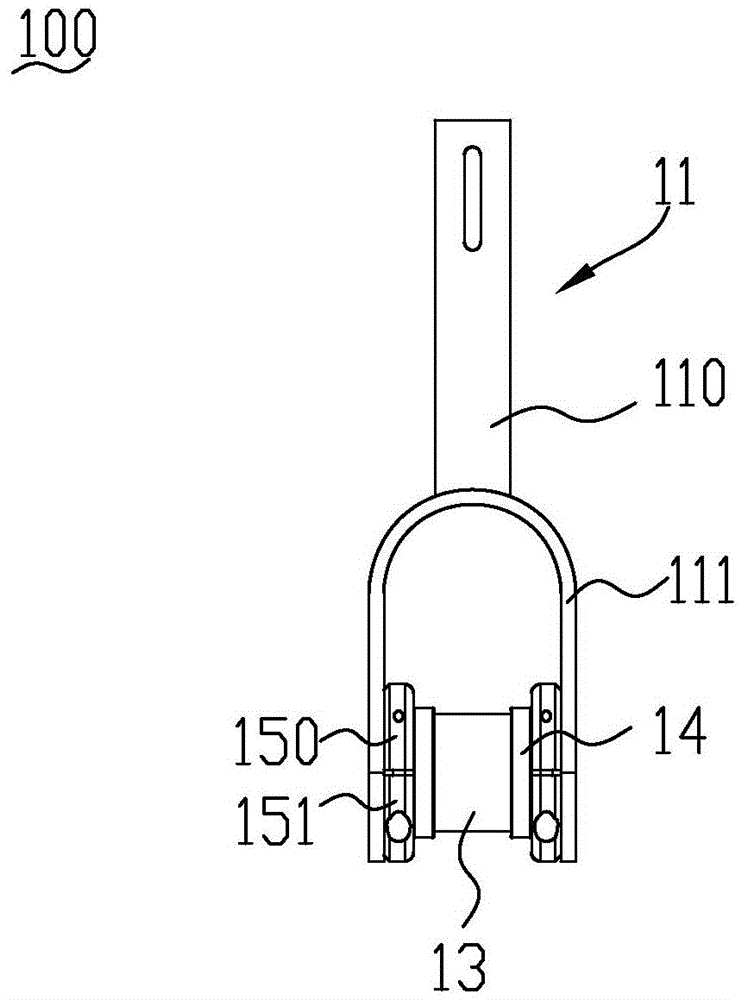

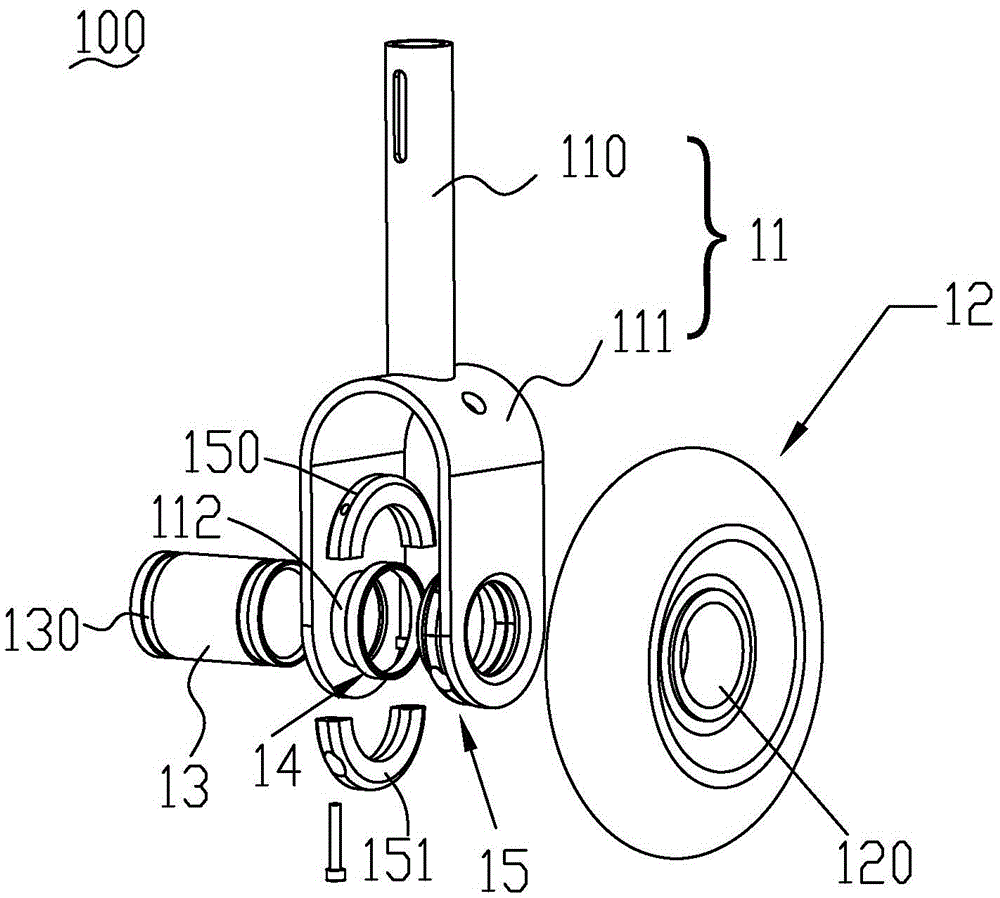

[0028] Attached figure 1 Attached Figure 4 The specific structure of the first embodiment of the present invention is shown. It discloses a wheel assembly without driving elements, which can be used as the front and rear wheels of bicycles and scooters, and can also be used as electric scooters, electric vehicles, motorcycles, etc. The non-driving wheel of a vehicle is generally the front wheel. The following uses the front wheel of a scooter as an example to illustrate the first embodiment of the present invention.

[0029] figure 1 The front wheel assembly 100 shown includes a hollow axle 13, a wheel carrier 11 with an axle hole 112 matching the outer diameter of the axle 13, and a wheel 12 rotatably connected to the axle 13. The wheel frame 11 includes a handlebar 110 connected with the frame body and a U-shaped fork frame 111. A pair of opposite wall surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com