Wet rotor motor pump

A technology of motor pump and rotor, applied in the field of wet rotor motor pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

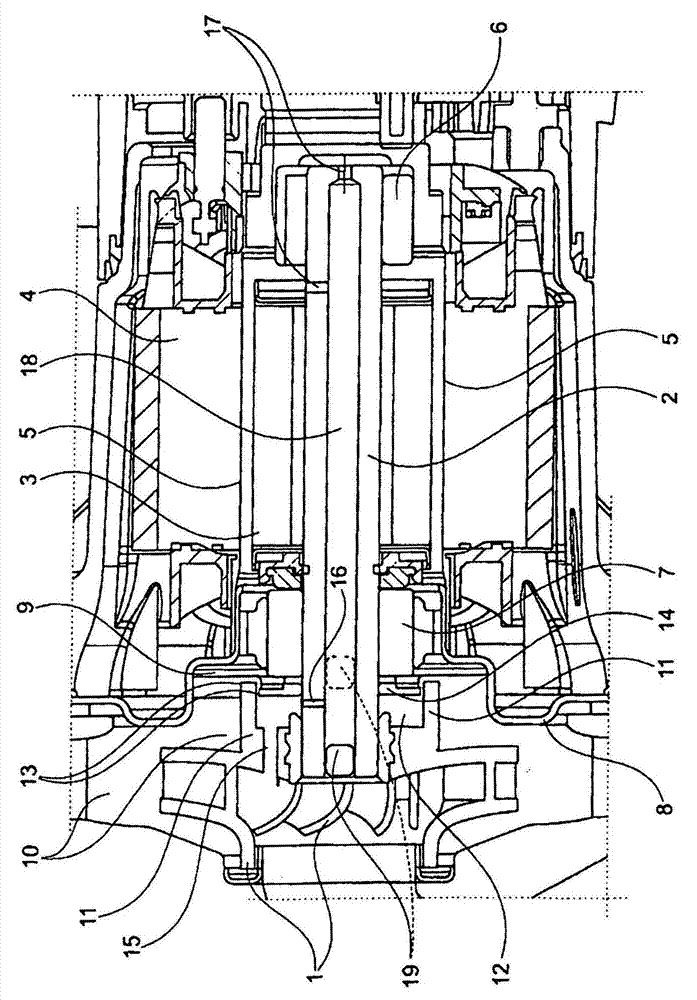

[0016] The wet rotor motor pump has, as a rotary pump, an impeller 1 driven by a coaxial hollow shaft 2 which supports a rotor assembly 3 which rotates in a stator 4 of the electric motor. The rotor assembly 3 is separated from the stator by a gap tube 5 through which the conveyed medium flows so that the bearings 6 , 7 located in the gap tube 5 are lubricated and cooled. The gap tube is closed at the rear, so that it can also be called a "gap pot".

[0017] At the end of the gap tube 5 facing the impeller, a gap tube flange 8 is formed, against which an annular separating wall 9 in the form of a sheet metal part rests in order to separate the pump chamber 10 from the interior of the gap tube 5 . At least one throughflow opening is located in the partition wall 9 , whereby the conveying medium reaches the interior of the gap tube 5 .

[0018] On the rear side of the pump impeller 1 , an annular projection 11 is integrally formed coaxially, so that an annular space 12 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com