Composition for the oxidation dyeing of keratin fibers, comprising particular fatty alcohols, a liquid fatty substance and a cationic polymer

A technology of keratin fibers, fatty substances, applied in the field of compositions for oxidative dyeing of keratin fibers containing specific fatty alcohols, liquid fatty substances and cationic polymers, capable of solving problems such as performance quality to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

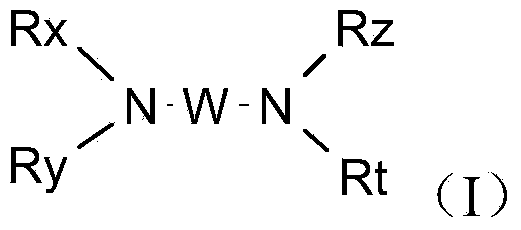

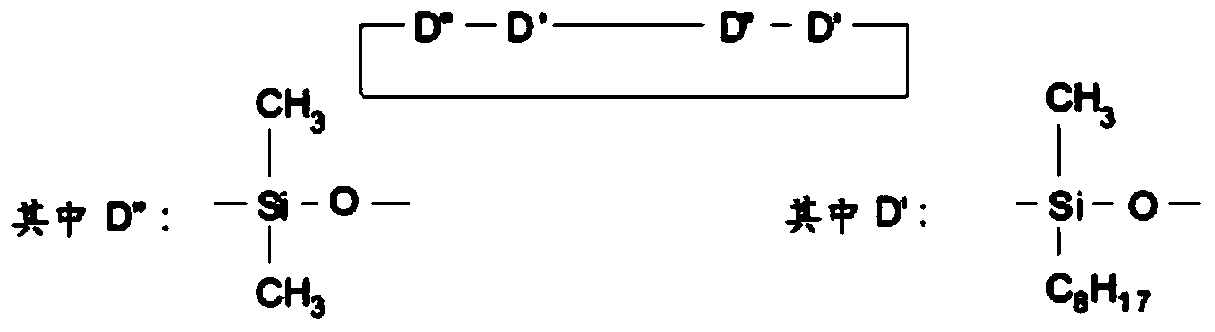

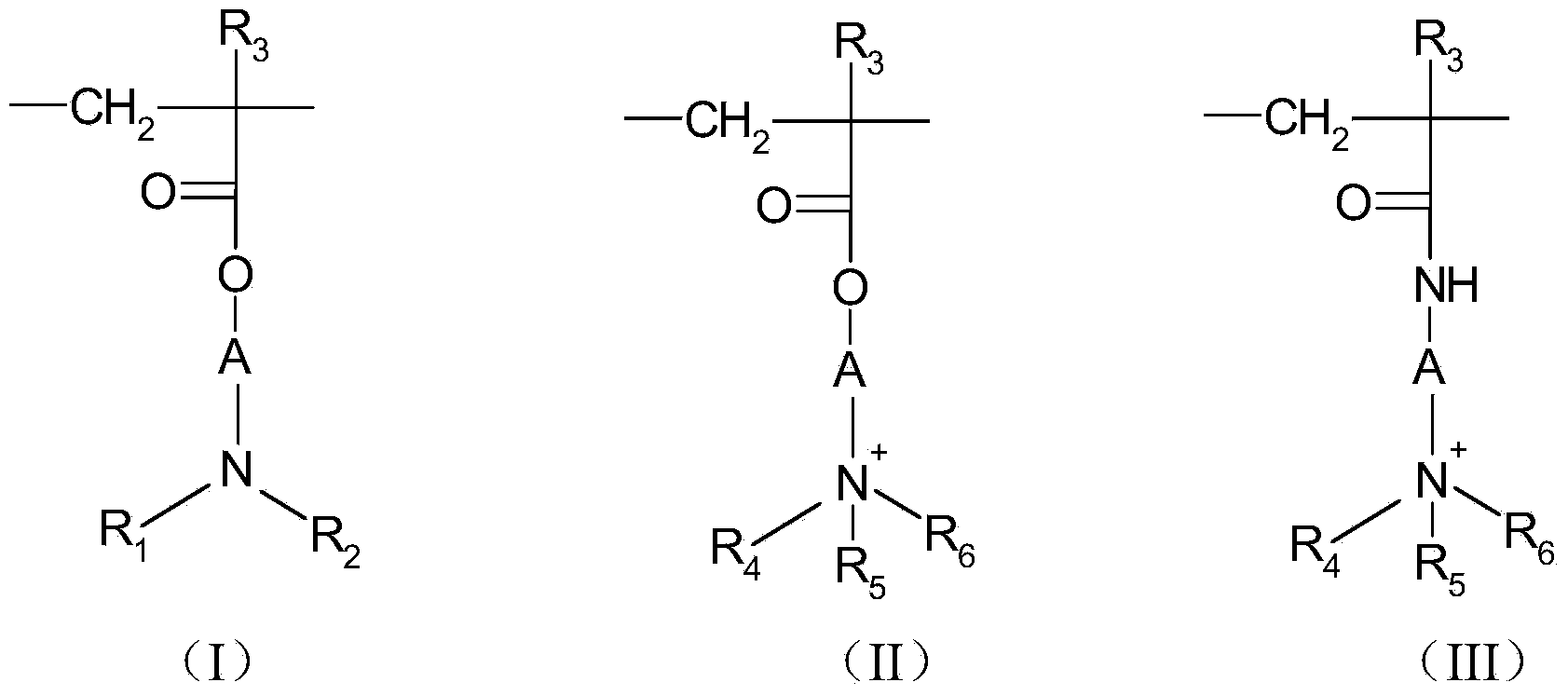

Method used

Image

Examples

Embodiment

[0423] The following oxidation dye compositions (A) were prepared (in the table below, amounts are expressed in grams of active substance):

[0424] Dye composition (A):

[0425]

[0426]

[0427] Oxidizing composition (B): (in grams of active substance)

6

0.04

Sodium pyrophosphate decahydrate

0.02

pentasodium pentetate

0.06

Glycerin

0.5

2.28

Cetyl stearyl alcohol with 25 OE

0.57

Trideceth-2 carboxamide MEA

0.85

water

make up to 100

[0429] For use the above composition is mixed in the following manner:

[0430] - the dye composition (A1) is mixed with the oxidizing composition (B) in a weight ratio of (A1):(B) of 1:1.5;

[0431] - the dye composition (A2) is mixed with the oxidizing composition (B) in a weight ratio of (A2):(B) of 1:1.5;

[0432] - the dye composition (A3) is mixed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com