Fall-off type feeding/moving/discharging system of automatic sampler

An automatic sampling and shedding technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of no feeding and unloading mechanism, poor applicability, difficult operation and connection, etc., to reduce pollution, clear discharge classification, speed and The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

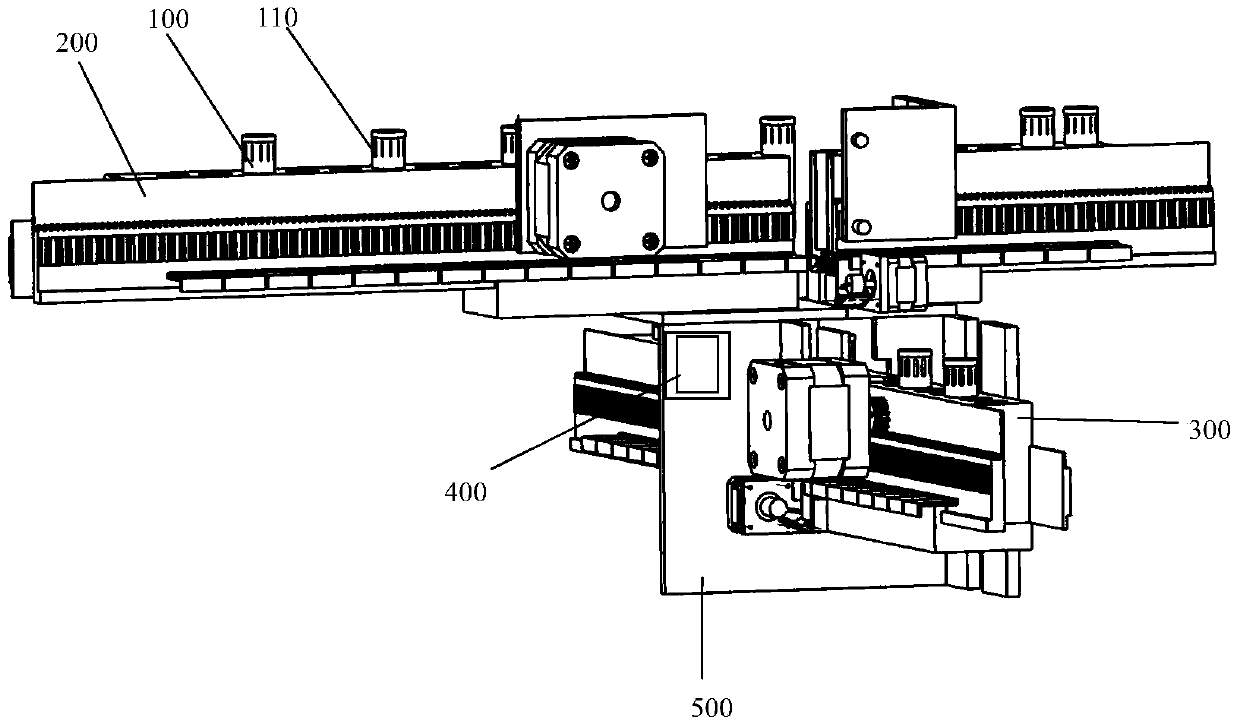

[0045] Referring to FIG. 1 , the feeding device 200 and the material moving device 300 are respectively fixed on the shell frame 500 , and the feeding device 200 is above the material moving device 300 .

[0046] The feeding device 200 and the material moving device 300 are respectively connected with the control device 400 .

[0047] The labels 110 are respectively on the containers 100, and each label 110 carries various agreed information.

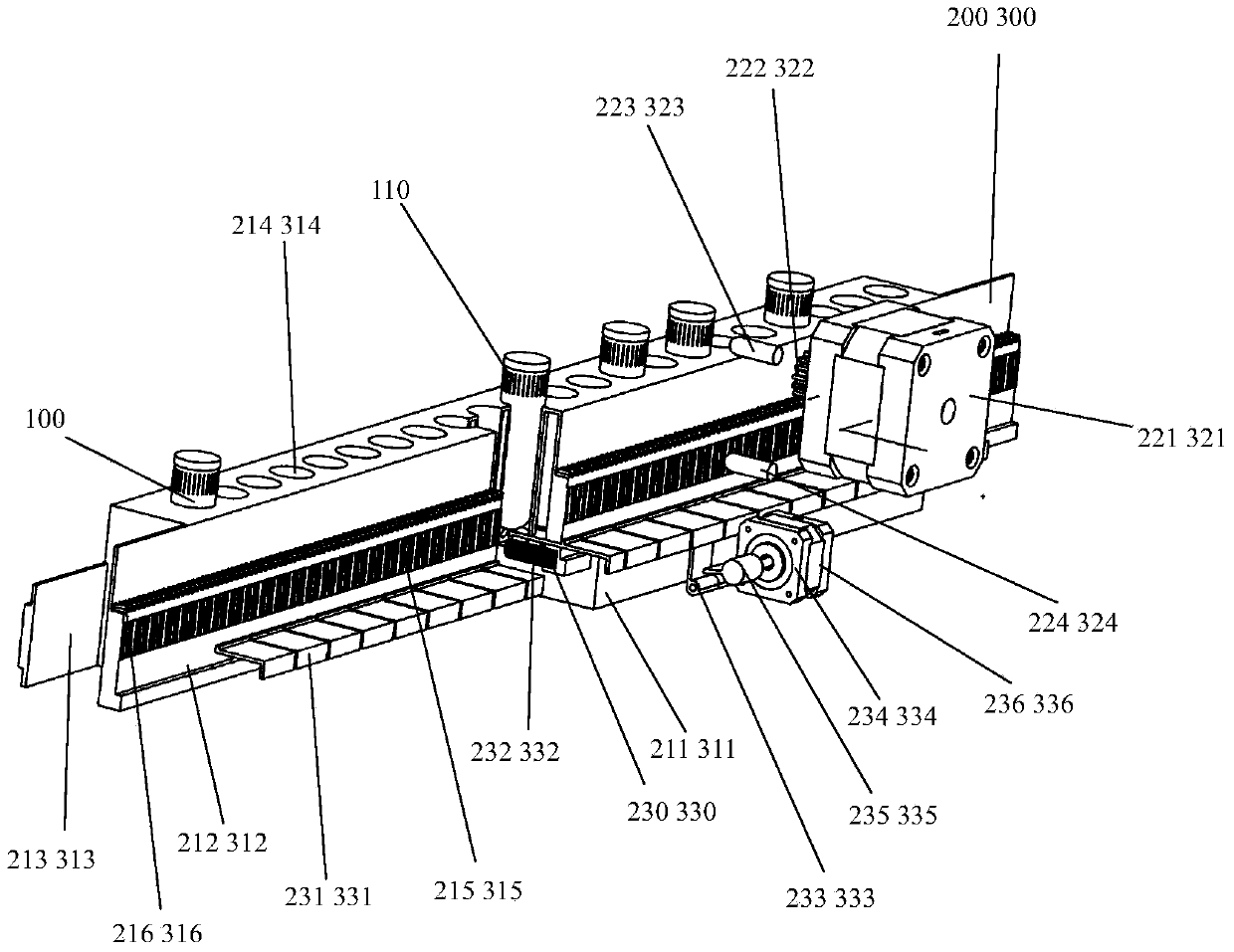

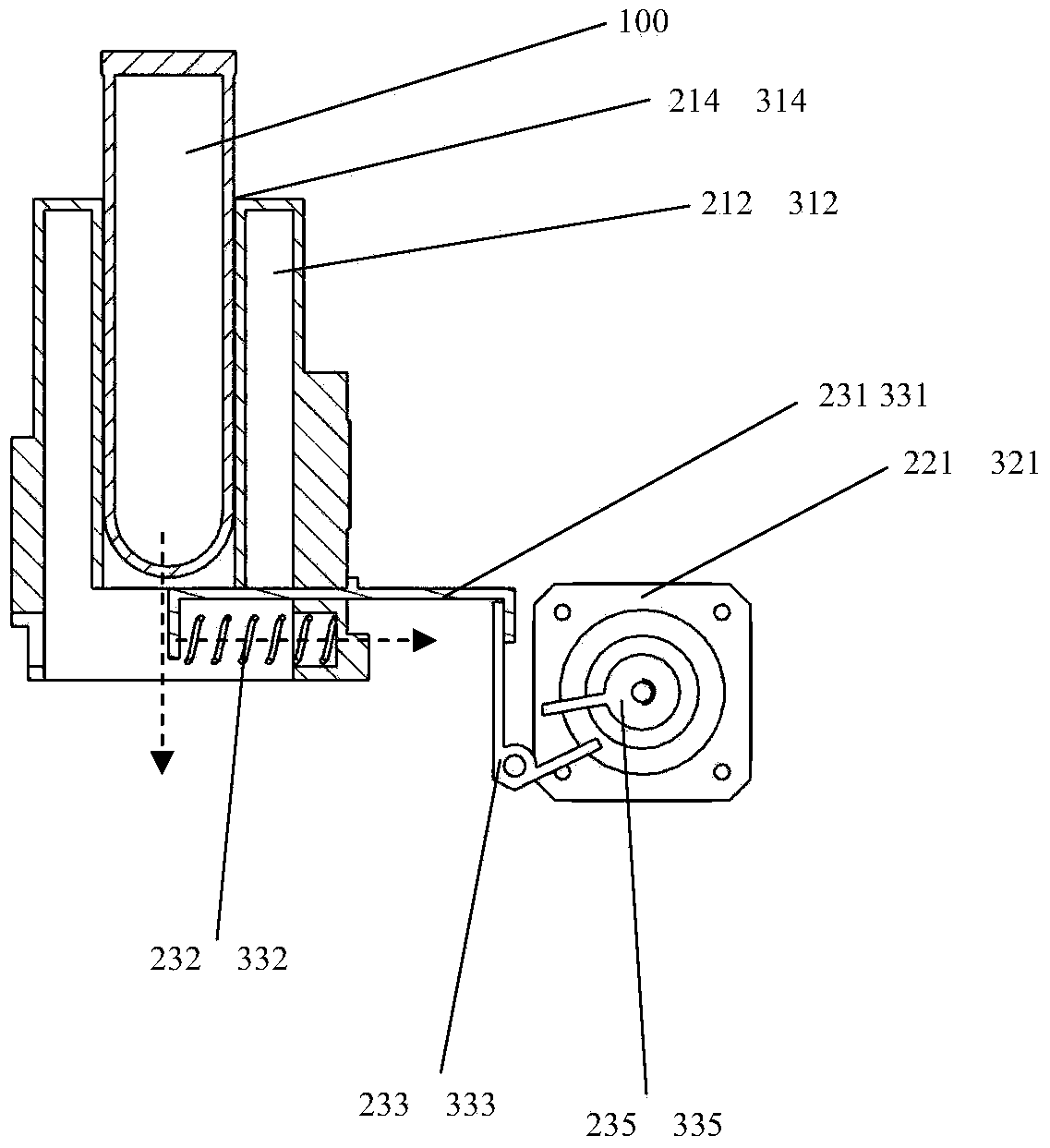

[0048] Fig. 2 is a sectional view of the feeding device 200 and the material moving device 300, image 3 It is a side sectional view of the feeding device 200 and the material moving device 300 .

[0049] Referring to Fig. 2, the feed chute frame 211 is fixed on the shell frame, the feed slide bar 212 slides in the feed chute frame 211, and the two ends of the feed slide bar 212 have a feed gap 213 respectively, and the feed slide bar 212 A plurality of feed holes 214 are arranged above the middle of the bar 212, the feed holes 214 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com