A lifting ring tilting mechanism

A technology of tilting mechanism and lifting ring, applied in drilling equipment, earth-moving drilling, drill pipe and other directions, can solve the problems of inability to grab heavy objects, small installation workload, difficulty in rotating the lifting ring, etc., to reduce drilling procedures and device safety. The effect of raising and increasing the component arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

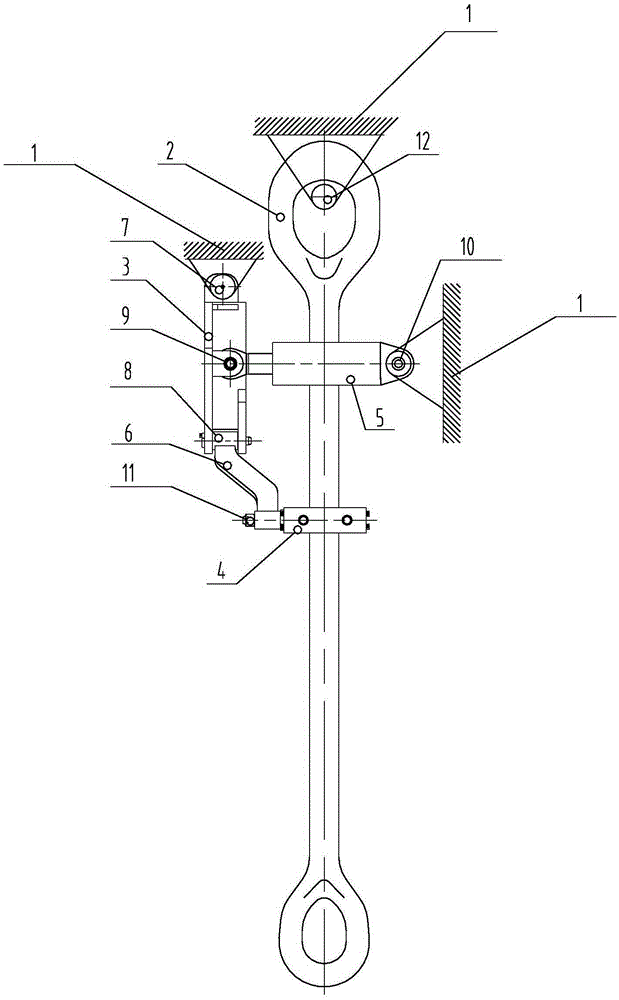

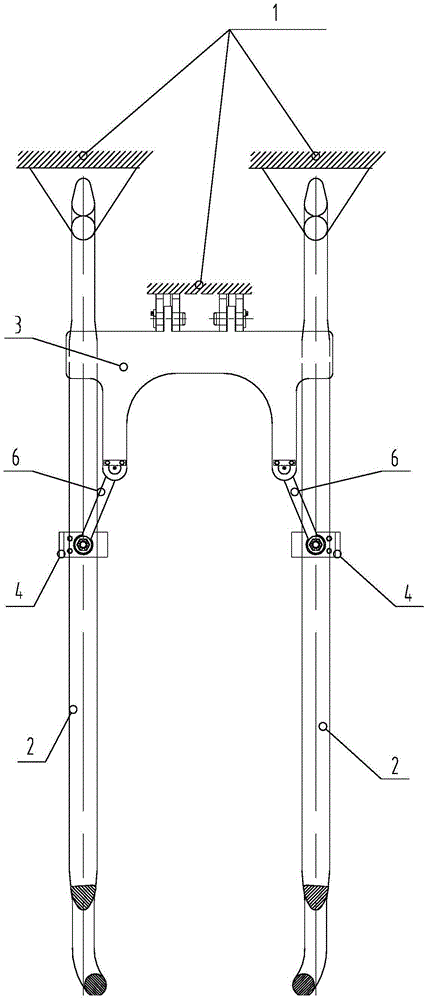

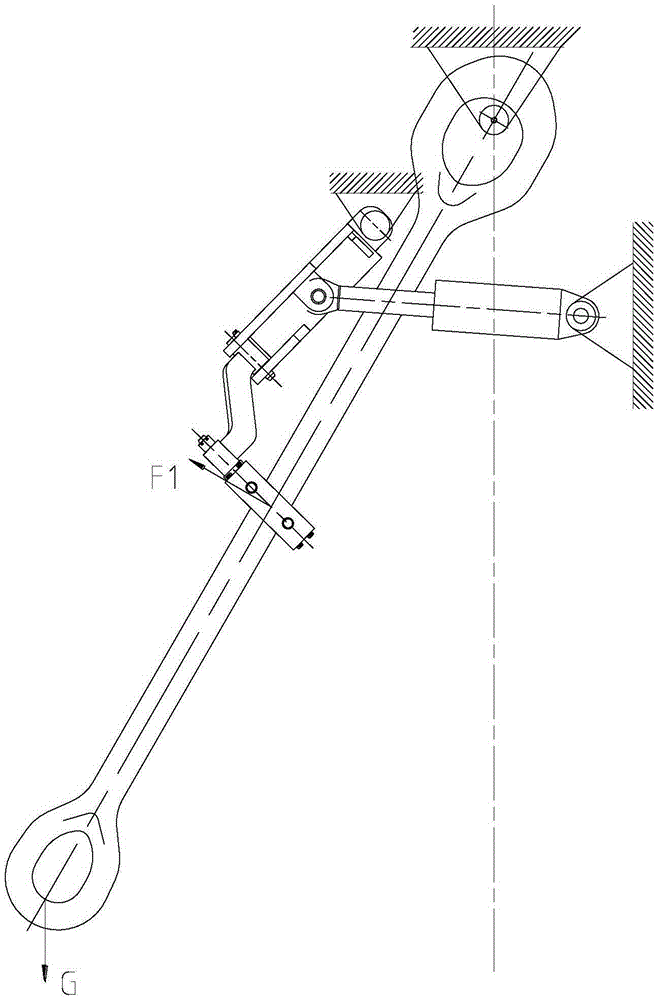

[0036] Such as Figure 1 to Figure 3 As shown, the lifting ring tilting mechanism of this embodiment includes a lifting ring 2, a bracket 3, a hoop 4 and an oil cylinder 5,

[0037] The upper end of the lifting ring 2 is hinged on the top drive body 1 through the sixth pin shaft 12, and the lifting ring 2 can rotate around the sixth pin shaft 12;

[0038] The upper end of the bracket 3 is hinged on the top drive body 1 through the first pin shaft 7, and the bracket 3 can rotate around the first pin shaft 7;

[0039] The lower end of support 3 is connected with connecting rod 6, and the upper end of connecting rod 6 is hinged with support 3 by the second bearing pin 8, and connecting rod 6 can rotate around the second bearing pin 8, and the axis line of the second bearing pin 8 and the first The axis lines of a pin shaft 7 are perpendicular to each other;

[0040] The lower end of connecting rod 6 is equipped with hoop 4, as Figure 4 As shown, the hoop 4 includes a roller b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com