Fine-count groove filter stick and fine-count groove composite filter stick

A groove and filter rod technology, applied in e-liquid filter, application, tobacco and other directions, can solve the problems of low hardness, large suction resistance, poor appearance, etc., to improve hardness, save consumption, ensure product appearance quality and smoke The effect of splice quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

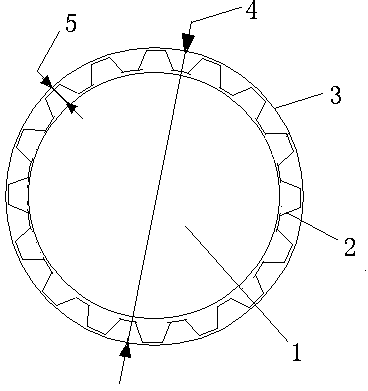

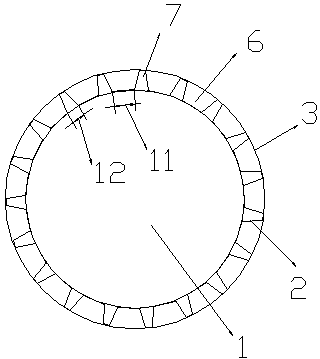

[0031] Such as figure 1 , figure 2 The fine grooved filter rod shown is composed of forming paper 3 and grooved cellulose paper wrapped around the filter core 1. The length of the filter rod is 120 mm, and the circumference of the filter rod is 17.5 mm (the diameter of the filter rod 4 is about 5.57 mm. ), the grooved cellulose paper is fine grooved cellulose paper 2, the grammage is 65g / m--2, and it contains 18 pairs of fine grooves composed of convex grooves 7 and concave grooves 6 The tooth shape of the thin branch groove is trapezoidal tooth, arc-shaped tooth or rectangular tooth 8, and the pressure depth 5 of the thin branch groove is 0.45mm; 100°C-130°C; all or part of the thin branch grooves are continuous along the length of the filter rod.

[0032] When the tooth shape of the thin-branched groove is trapezoidal or rectangular, the bottom opening 12 of the convex groove is smaller than the bottom edge 11 of the concave groove. The width of the bottom opening 12 of...

Embodiment 2

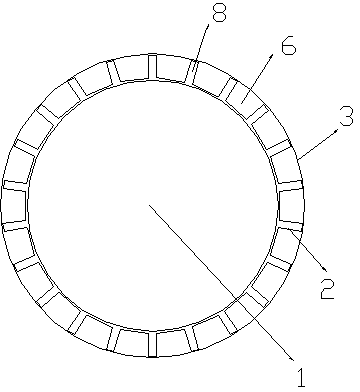

[0034] Such as image 3 For the thin-grooved filter rod shown, the top width of the convex groove 7 is equal to the width of the bottom opening 12, the tooth shape of the convex groove 7 is a rectangular tooth, and the tooth shape of the concave groove 6 is a trapezoidal tooth .

Embodiment 3

[0036] Such as Figure 4 In the cross-section of the thin-branched groove composite filter rod shown, the two sides of the convex groove 7 are glued together to form a radial shape of fins 9, and the thickness of the fins 9 is two layers of cellulose paper. thickness of. The fiber material of the filter element 1 does not enter into the convex groove 7, and the filter element 1 maintains good roundness and stable filtering performance. After the fine-groove filter rod is cut, the short-cut filter rods of the ordinary fine-branch acetate fiber filter rod with the same circumference are connected end to end and spliced together, and the same outer ring forming paper is wrapped to form a fine-groove composite filter rod. Great.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com