Ink powder prevention bearing mechanism of paper box of image forming device

A toner and bearing technology, applied in the field of image forming devices, achieves the effects of cost reduction, improved user experience and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

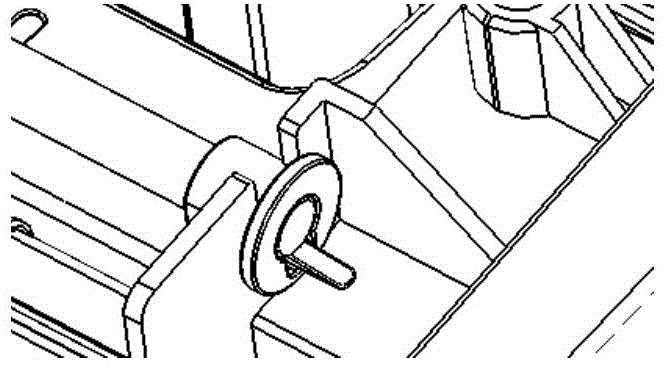

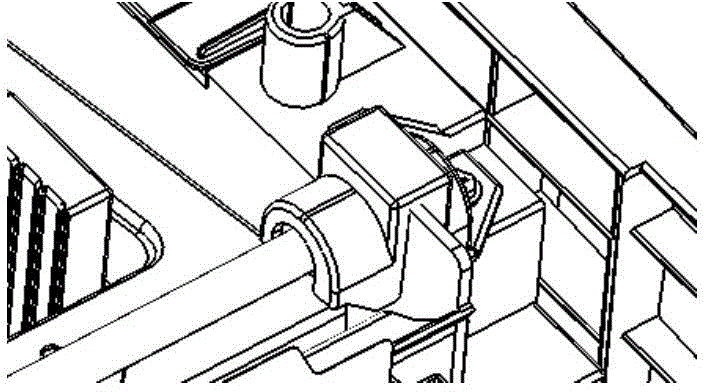

[0027] see Figure 3-6 , a carton anti-toner bearing mechanism of a copier, comprising a paper feed shaft 1, an anti-toner bearing 3; the anti-toner bearing 3 includes a main bearing 3b, and the outer end surface of the main bearing 3b is connected to a baffle 3d , the upper half of the inner end surface of the main bearing 3b has an arc-shaped cap 3a extending axially inward, and the inner side of the arc-shaped cap 3a is provided with a rib 3a1 along the axial direction, and the rib 3a1 is in contact with the paper feeding shaft 1; The outer end surface of the baffle plate 3d is also connected to the dustproof cap 3c.

[0028] The main bearing 3b is provided with an elastic buckle 3b1. The elastic buckle 3b1 is provided with an annular groove in the radial direction of the paper feeding shaft 1. The elastic buckle 3b1 is pressed into the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com