Self-sensing conical roller bearing for wind driven generator

A technology for tapered roller bearings and wind turbines, applied in the directions of roller bearings, bearing components, shafts and bearings, etc., can solve the problem of difficulty in obtaining the running status of bearings in a timely and accurate manner, and improve reliability and power generation. The effect of strong power supply capacity and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

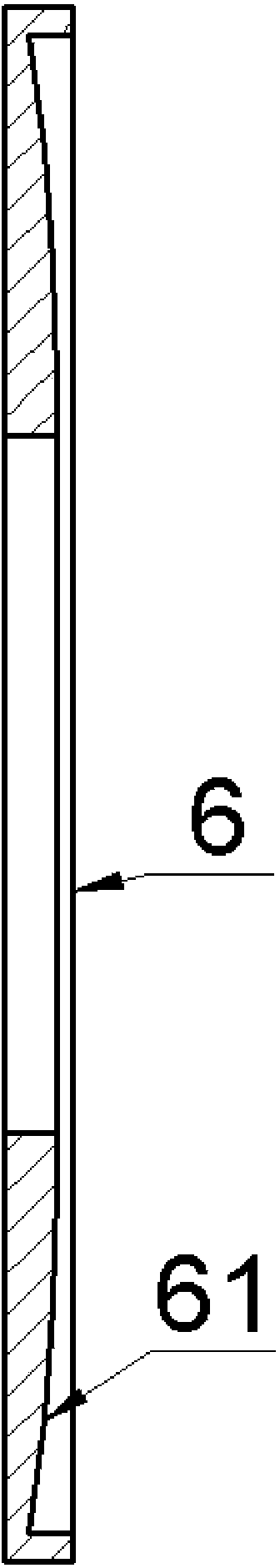

[0017] Such as Figure 1 to Figure 6 As shown, it includes an inner ring 1, a cone 2, a cage 3, and an outer ring 4. The right end of the inner ring 1 is provided with a stepped shaft 11, and the left end of the outer ring 4 is provided with a stepped hole 41. The inner ring 1 The left end and the right end of the outer ring 4 are respectively inlaid with a group of excitation magnets C2, and the stepped shaft 11 of the inner ring 1 and the stepped hole 41 of the outer ring 4 are respectively installed with a right disk 5 and a left disk 5' through interference fit, The right disc 5 is provided with a right step ring groove 51 and a right guide hole 52, and the left disc 5' is provided with a left step ring groove 51' and a left guide hole 52', and the right disc 5 and the left disc 5 The right pressing plate 6 and the left pressing plate 6' are respectively installed on the ' by screws, and the right pressing plate 6 and the left pressing plate 6' are respectively provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com