A High-Speed Cylindrical Roller Bearing with Self-Generating Monitoring Device

A technology for cylindrical roller bearings and monitoring devices, which is applied to roller bearings, bearing components, shafts and bearings, etc., can solve the problems of piezoelectric vibrators difficult to obtain kinetic energy, short overlapping time, and vibration, and achieve novel structure and power generation The effect of large amount and effective speed bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

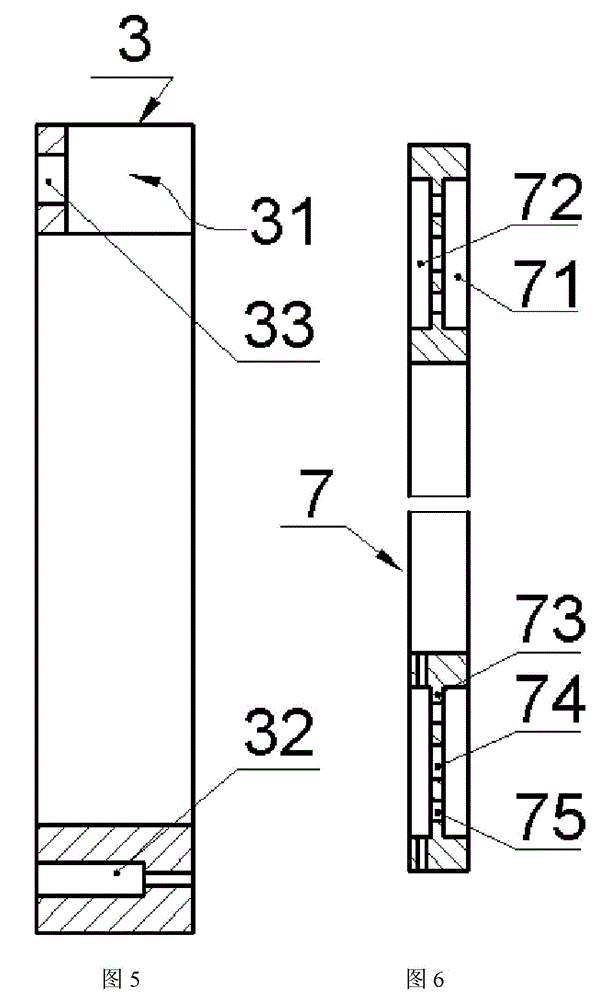

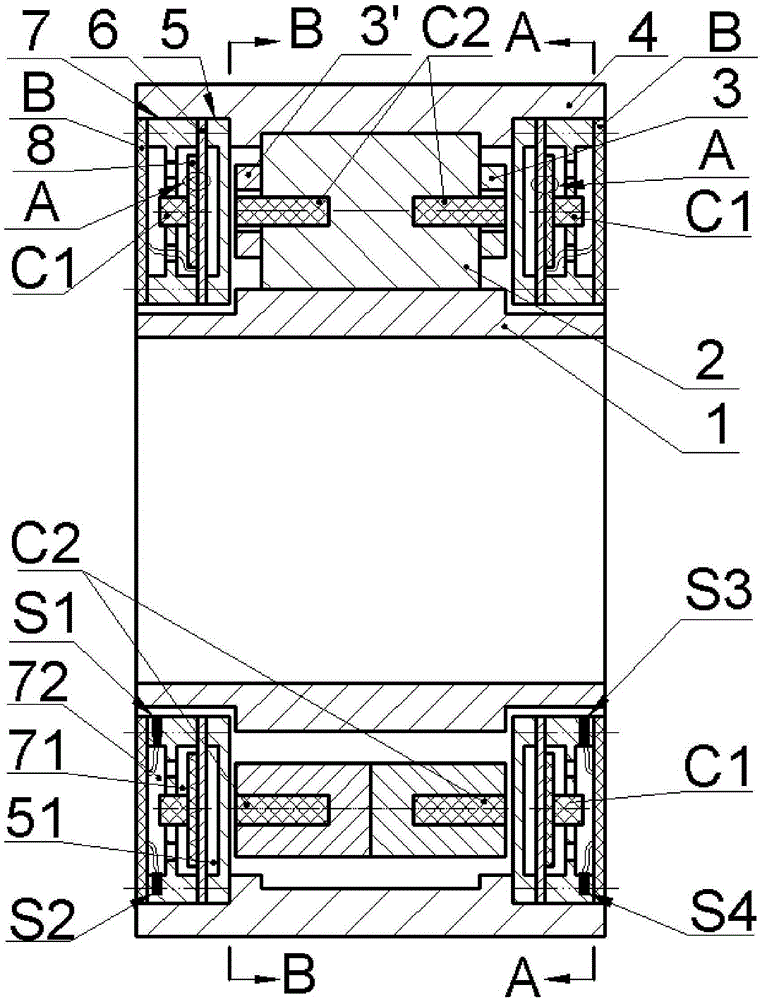

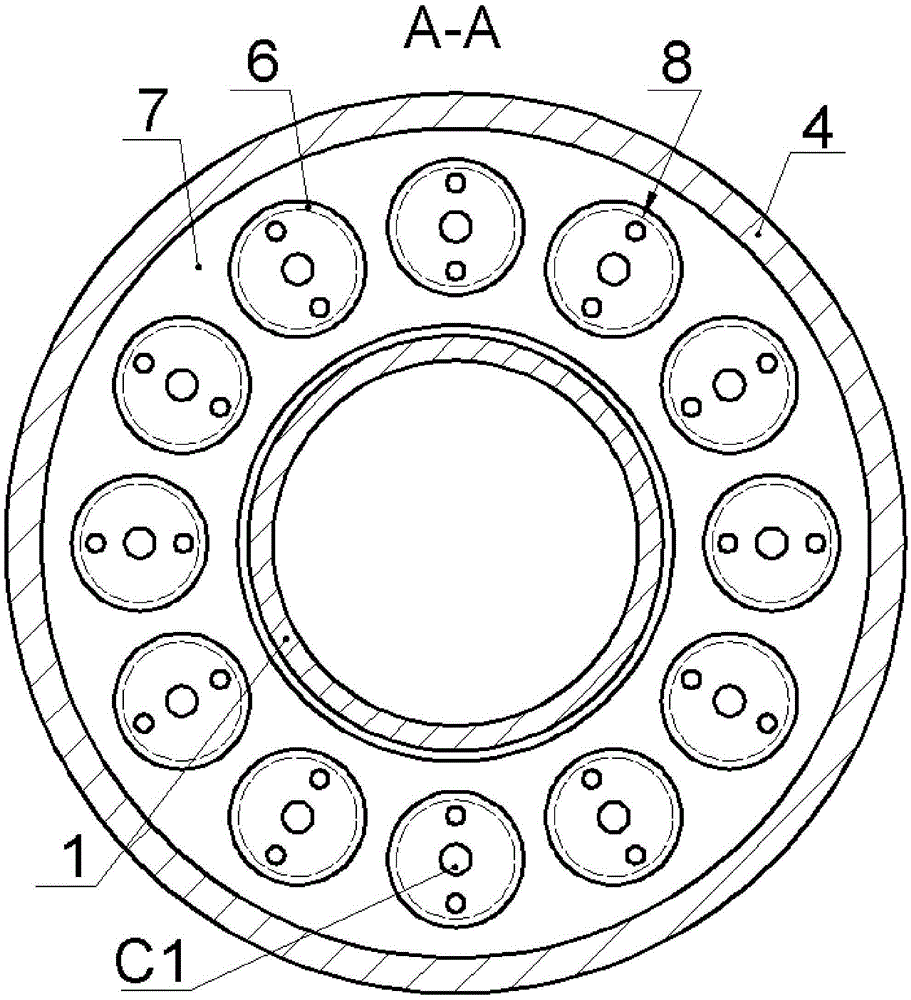

[0019] Such as Figure 1 to Figure 6 As shown, including inner ring 1, cylinder 2, outer ring 4, cage one 3 and cage two 3' are provided with cavity 31, stepped hole 32 and through hole 33, cage one 3 and cage two 3 'and the excitation magnet C2 embedded in the stepped hole 32 of the cage one 3 and cage two 3' are riveted by rivets, and the two cylinders 2 placed in the cavity 31 of the cage one 3 and cage two 3' One end of the excitation magnet C2 is inlaid with an excitation magnet C2, and one end of the excitation magnet C2 protrudes from the through hole 33 on the cage one 3 and the cage two 3'; Both ends are provided with stepped holes 41, and the disc body 7 is installed on the stepped shaft 11 or in the stepped holes 41 through interference fit. The two sides of the disc body 7 are respectively provided with a sink cavity 71 and an annular groove 72. The sink cavity 71 and The bottom wall 73 in the middle of the ring groove 72 is provided with a guide hole 74 and a wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com