Underground engineering roadway yielding support system

A technology for underground engineering and shaft roadway, which is applied in pillars/brackets, mining equipment, earthwork drilling and mining, etc., and can solve problems such as failure to achieve the expected support-surrounding rock integrated support effect, constant working resistance, and inability to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples, but the scope of protection required by the present invention is not limited to the scope described in the specific examples.

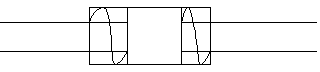

[0019] A yielding support system for wells and lanes in underground engineering, including yielding hydraulic props 4, yielding anchors 2, meshes 3, steel beams 5, pressure sensors 13, and controllers 14, and the meshes are laid on the surrounding rock of the roadway 1 3. Use the pressure anchor 2 to support the surrounding rock of the roadway, erect the steel beam 5, and perform roof support through the pressure hydraulic column 4; Rod 2 provides pressure support for the deformation of the surrounding rock to give full play to the self-stabilization ability of the surrounding rock. When the pressure support system yields to a certain extent, the interaction between the surrounding rock and the support system reaches a stable and balanced support state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com