Hardware assembly of externally opened hopper window and externally opened hopper window

A technology of hardware and components, applied in the field of window products, can solve problems such as loose self-tapping screws of hardware components, easy damage of window hardware components, poor anti-theft performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

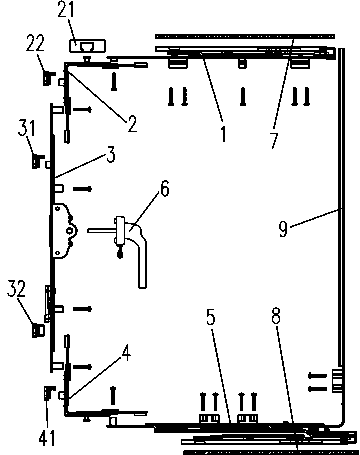

[0229] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 shown.

[0230] The hardware components include: upper sliding brace 1, corner driver A2, driver 3, corner driver B4, lower brace 5, handle 6, window frame lining board A7, window frame lining board B8, sash cover 9, Anti-theft screw, overhanging lock seat 21, lock block A22, lock block B31, anti-mistake lock block 32, lock block C41 and safety anti-theft lock 601.

[0231] The upper sliding brace 1 includes: upper sliding brace seat 101, upper sliding brace connecting rod A102, upper sliding brace connecting rod B103, upper sliding brace connecting rod C104, upper sliding brace connecting rod D105, upper sliding brace fixing head 106, upper sliding brace Slide rod fixing screw A107, upper sliding brace anti-theft screw...

Embodiment 2

[0345] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 shown.

[0346] As long as the embodiment one Figure 10 , Figure 11 Remove the sliding brace connecting rod G508 and the sliding brace connecting rod H509, which is the second embodiment of the present invention, and other installation methods, usage methods, working principles and functions are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com