Automatic guiding system and method of tower crane

A technology for tower cranes and automatic guidance, which is applied in the directions of cranes, load hanging components, transportation and packaging, etc., which can solve the problems of slow operation, low efficiency, and inability to clearly see the operation area, so as to reduce cumbersome work and reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

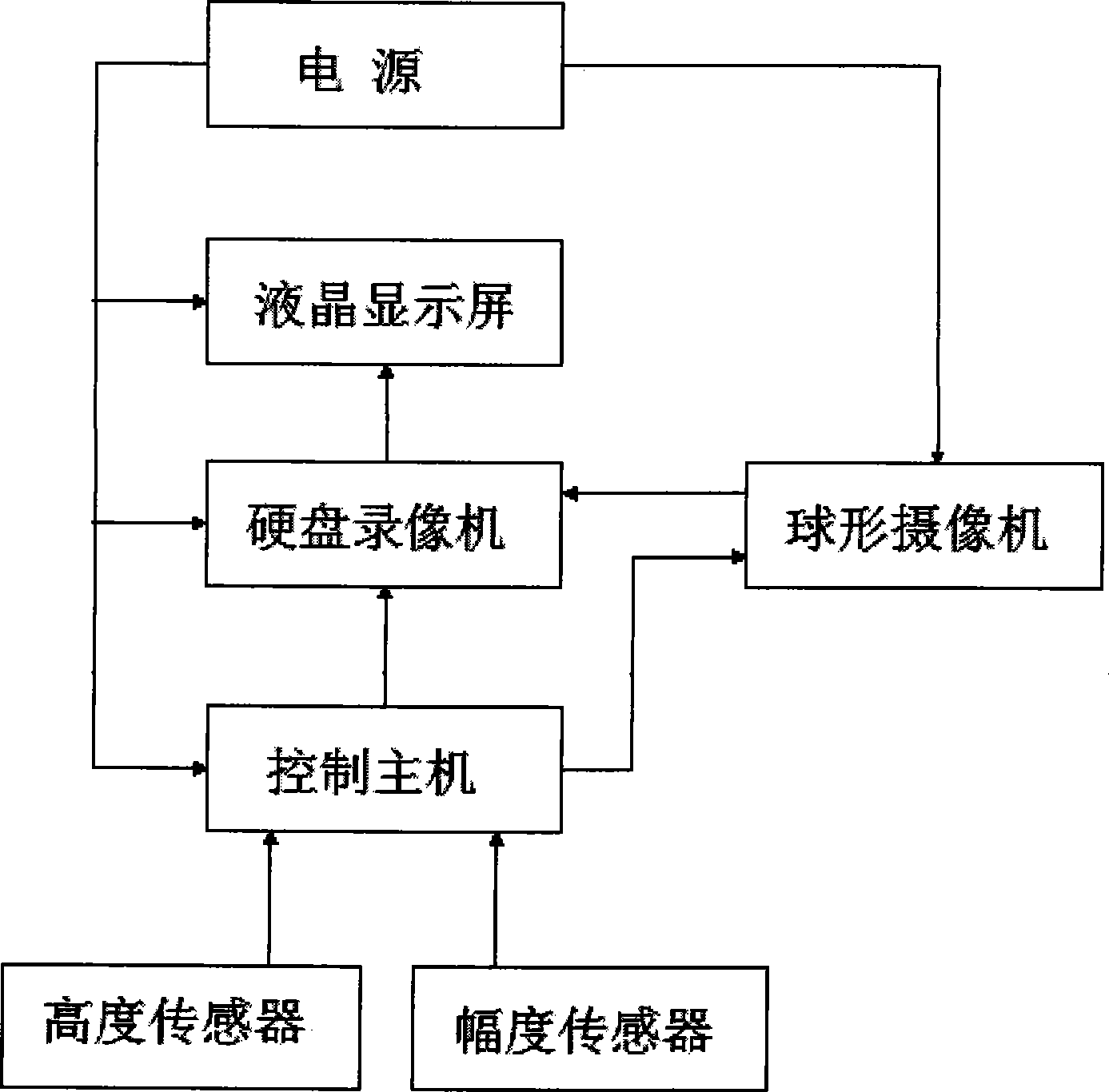

[0055] figure 1 It is an automatic guidance system for tower cranes. It consists of a control host, a spherical camera, a hard disk video recorder, a liquid crystal display, a height sensor, and an amplitude sensor.

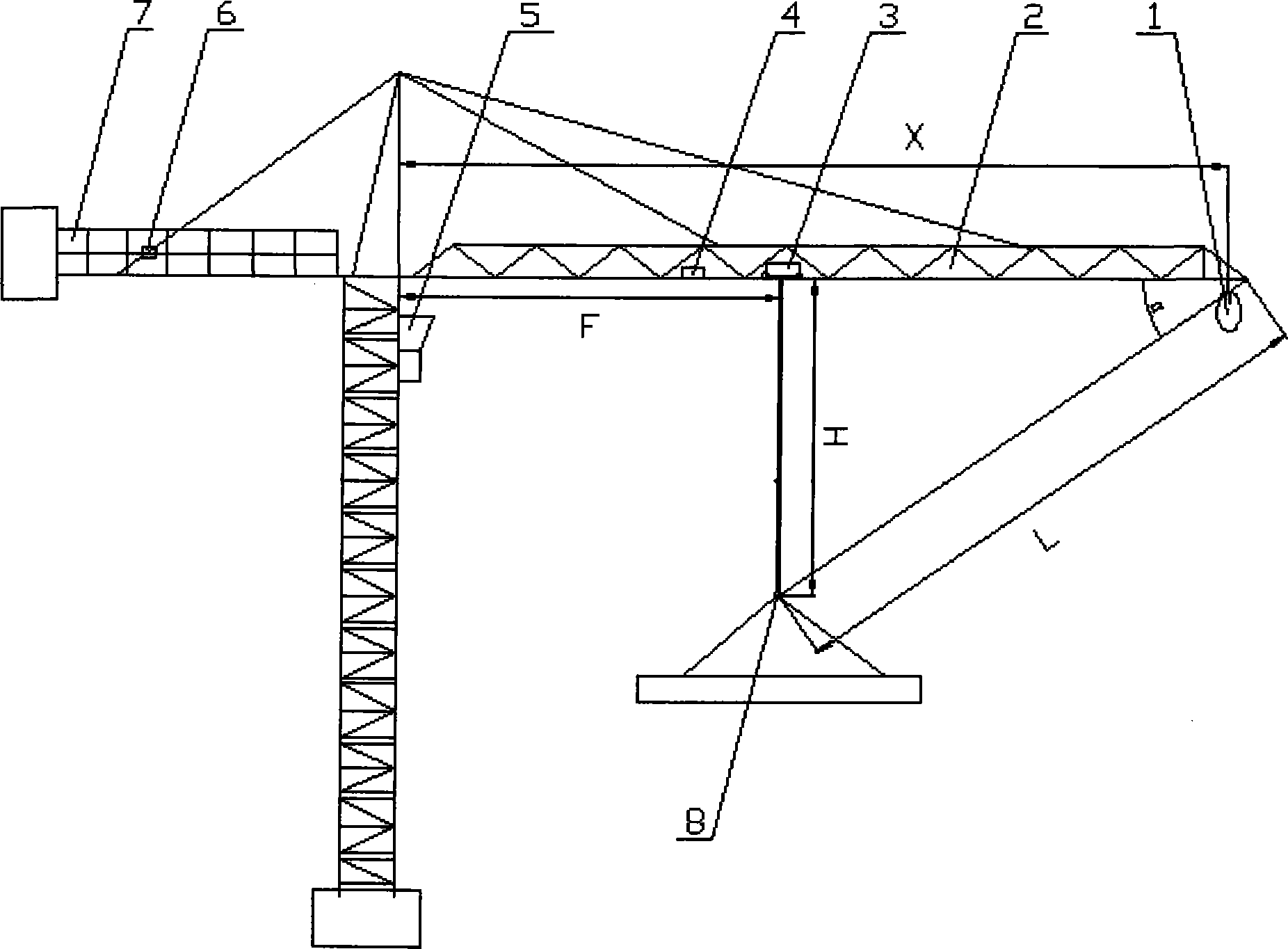

[0056] Among them, the control host, hard disk video recorder and high-definition liquid crystal display are all installed in the cab 5 of the tower crane. The spherical camera 1 is installed at the front end of the boom 2 of the tower crane.

[0057] Among them, the control host uses an ARM-based single-chip microcomputer as the main processor.

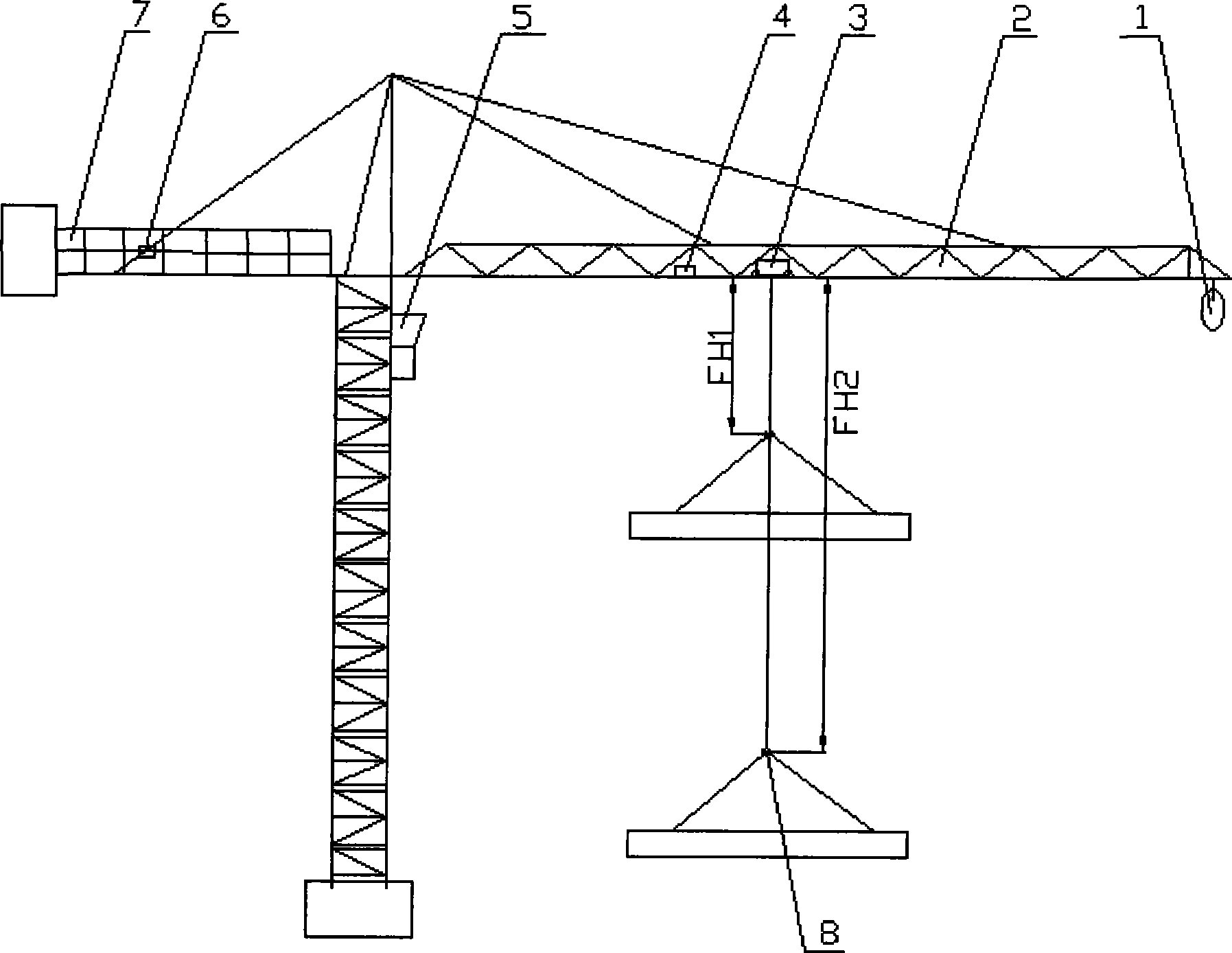

[0058] On the boom 2 of the tower crane, a boom winch 4 is housed, and the boom winch is used to change the height of the suspension hook 8 .

[0059] A balance arm hoist 6 is installed on the balance arm 7, and the balance arm hoist is used to change the moving distance of the luffing trolley 3.

[0060] Both the height sensor and the amplitude sensor are high-precision resistive sensors (type DXZ1: 660W stroke lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com