A device and method for realizing online recycling of rare earth polishing slurry

A rare earth polishing and rare earth polishing powder technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of consuming large material resources and power costs, affecting the slurry turnover efficiency of production and operation of upstream enterprises, etc. Achieve the effect of eliminating surface wrapping, avoiding the consumption of a lot of resources and logistics costs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

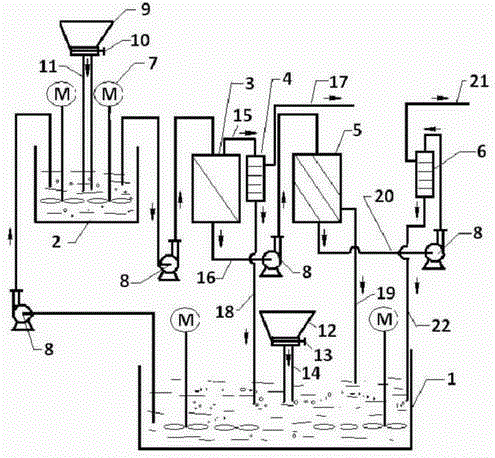

[0029] Referring to the accompanying drawings, a device for realizing online recycling of rare earth polishing slurry consists of a slurry tank (1), a slurry mixing tank (2), a cyclone separator (3), a pressure filter (4), and a fine filter (5), filter press 2 (6), leveling agent hopper (9), and powder hopper (12); the slurry tank (1) is equipped with agitator (7), and is connected to the slurry mixing tank through the delivery pump (8) (2) are connected; the pulp mixing pool (2) is attached with the agitator (7), and is connected with the cyclone separator (3) through the delivery pump (8); the cyclone separator (3) is attached with the light phase pipeline (15) and The pressure filter one (4) is connected with the heavy phase pipeline (16) and connected with the fine filter (5) through the transfer pump (8); the pressure filter one (4) is attached with the slag discharge pipeline (17) and the liquid discharge pipeline (18 ) and connected to the slurry tank (1); the fine filt...

Embodiment 2

[0040] Referring to the accompanying drawings, a device for realizing online recycling of rare earth polishing slurry consists of a slurry tank (1), a slurry mixing tank (2), a cyclone separator (3), a pressure filter (4), and a fine filter (5), filter press 2 (6), leveling agent hopper (9), and powder hopper (12); the slurry tank (1) is equipped with agitator (7), and is connected to the slurry mixing tank through the delivery pump (8) (2) are connected; the pulp mixing pool (2) is attached with the agitator (7), and is connected with the cyclone separator (3) through the delivery pump (8); the cyclone separator (3) is attached with the light phase pipeline (15) and The pressure filter one (4) is connected with the heavy phase pipeline (16) and connected with the fine filter (5) through the transfer pump (8); the pressure filter one (4) is attached with the slag discharge pipeline (17) and the liquid discharge pipeline (18 ) and connected to the slurry tank (1); the fine filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com