Rod piece welding machine

A welding machine and rod technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problem that welding equipment such as door welding machine operating machine cannot meet production requirements, and achieve simple structure, high welding accuracy, and low The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific drawings.

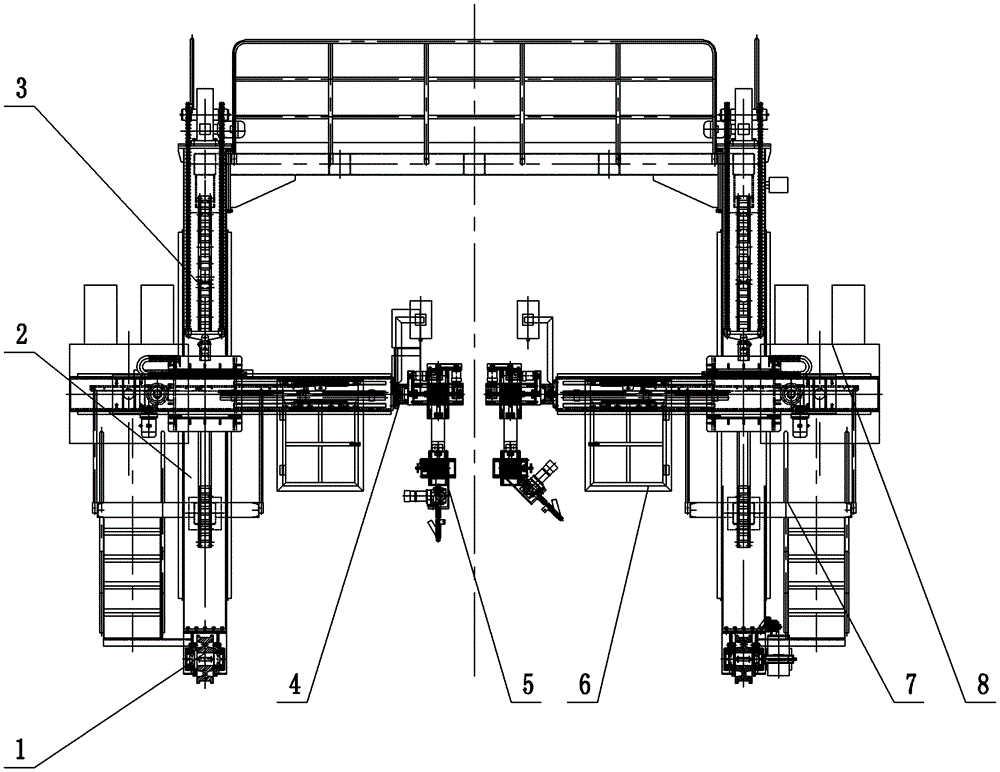

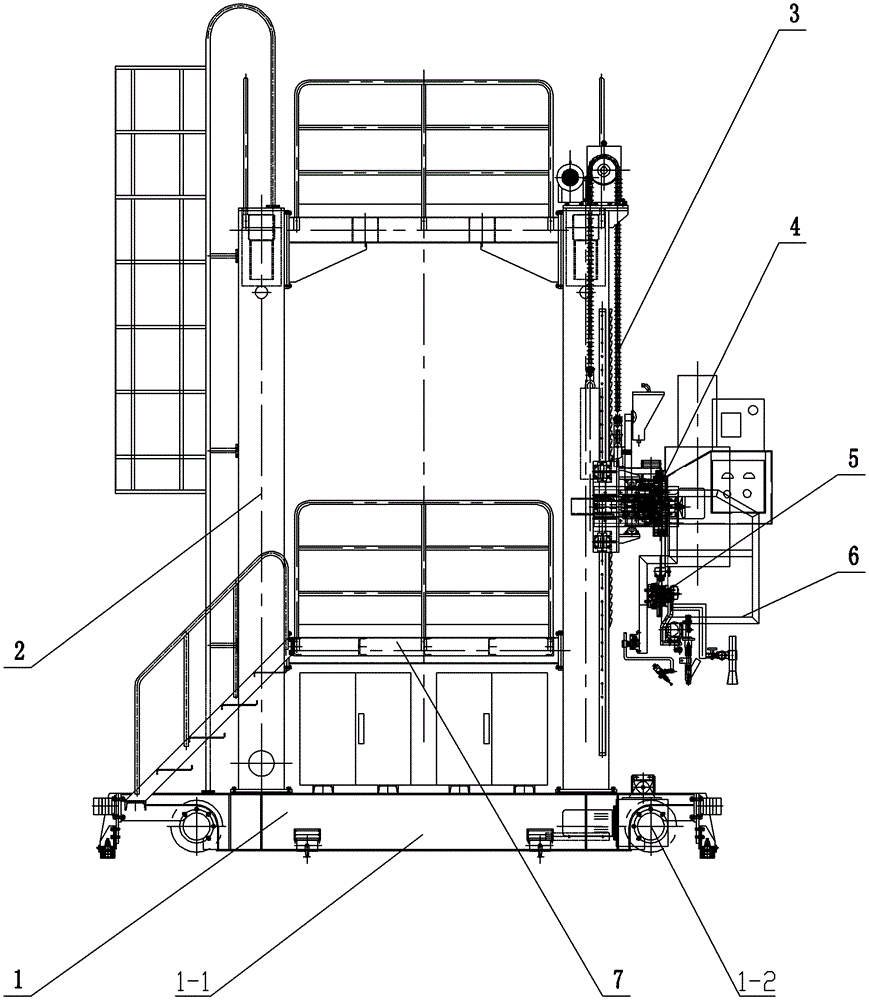

[0034] Such as Figure 1 ~ Figure 2 As shown: the rod welding machine includes a traveling mechanism 1, a gantry 2, a welding arm lifting mechanism 3, a weld seam servo tracking mechanism 4, a welding torch three-dimensional adjustment mechanism 5, an operation table 6, a loading platform 7, and a flux conveying and recycling system 8 etc.;

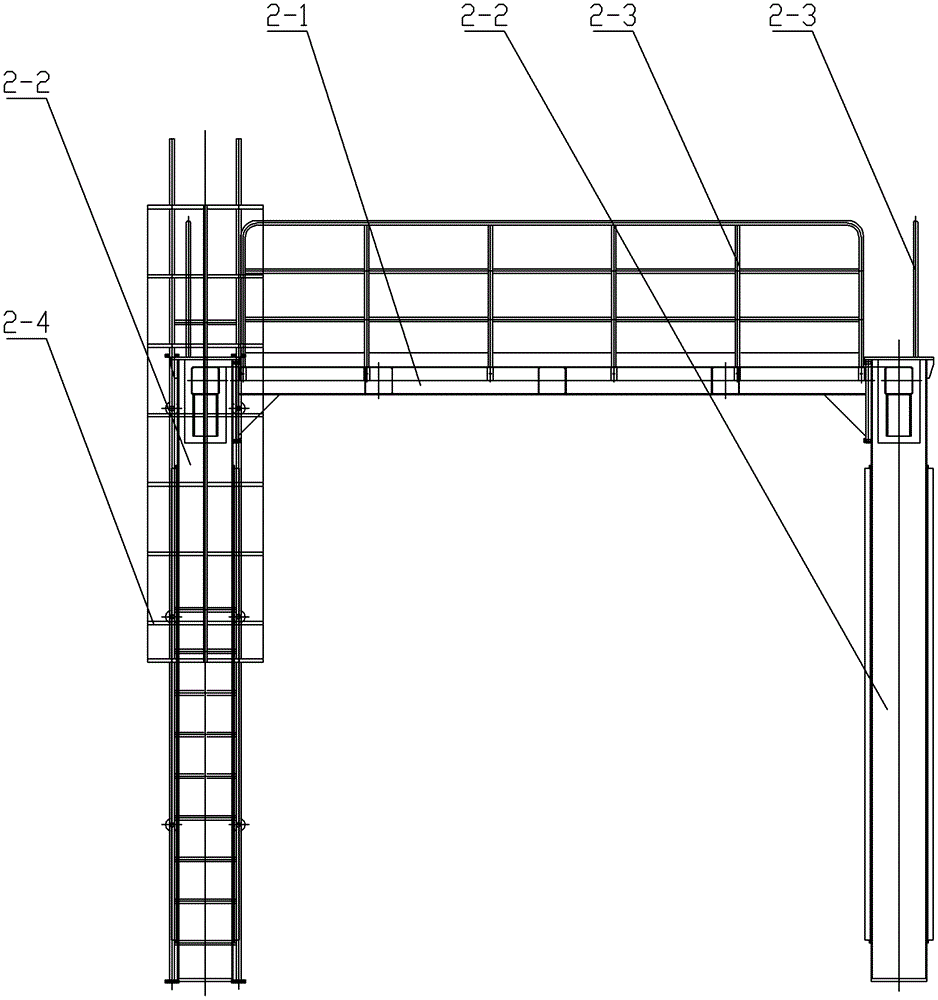

[0035] Such as Figure 3 ~ Figure 4 : the gantry includes a gantry platform 2-1, a gantry column 2-2, a gantry guardrail 2-3, and a gantry ladder 2-4;

[0036] Such as Figure 5 ~ Figure 6 , Figure 15 As shown: the welding arm elevator 3 includes a first reducer 3-1, a sprocket 3-2, a chain 3-3, a first coupling block 3-4, a counterweight 3-5, and a second coupling block 3-6 , shoulder pole 3-7, ratchet 3-8, first coupling seat 3-9, guide seat 3-10, first slide rail 3-11, first slider 3-12, cross arm 3-13, second Slide rail 3-14, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com