Upper die of stamping die and stamping die

A technology for stamping dies and mold bases, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., and can solve the problems of inconvenient installation of elastic elements 6, inconvenient installation of side pins 2, and inability to provide enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide an upper die of a stamping die, which can provide sufficient installation space for the elastic element. Another core of the present invention is to provide a stamping die comprising the above-mentioned upper die.

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

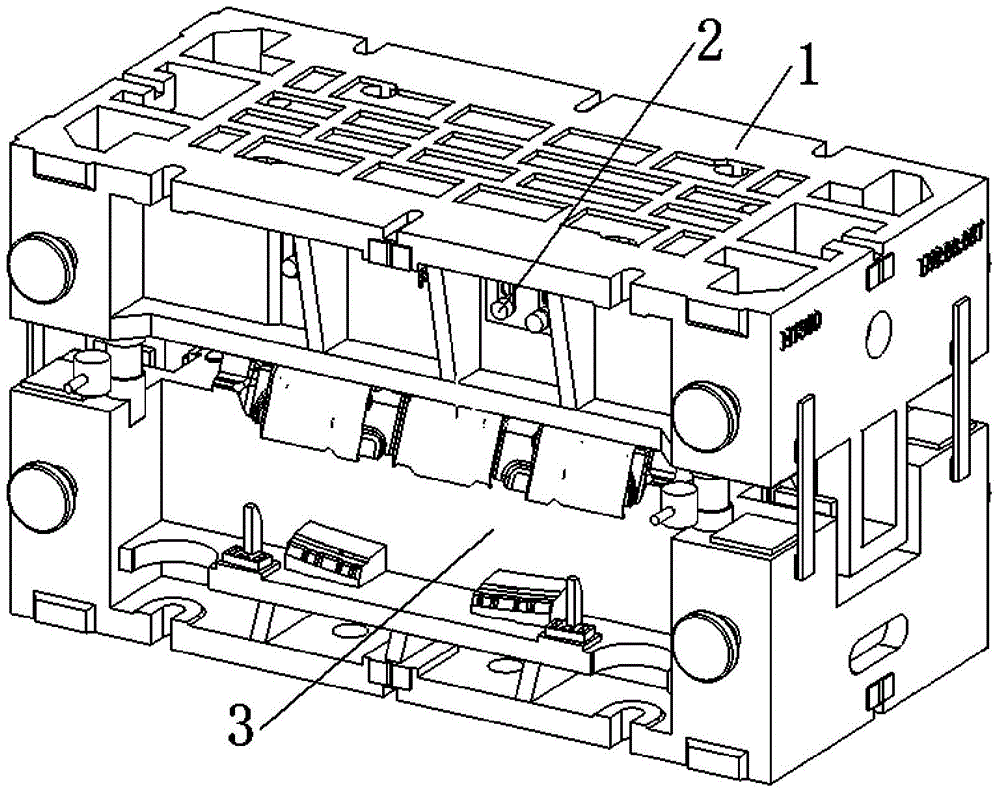

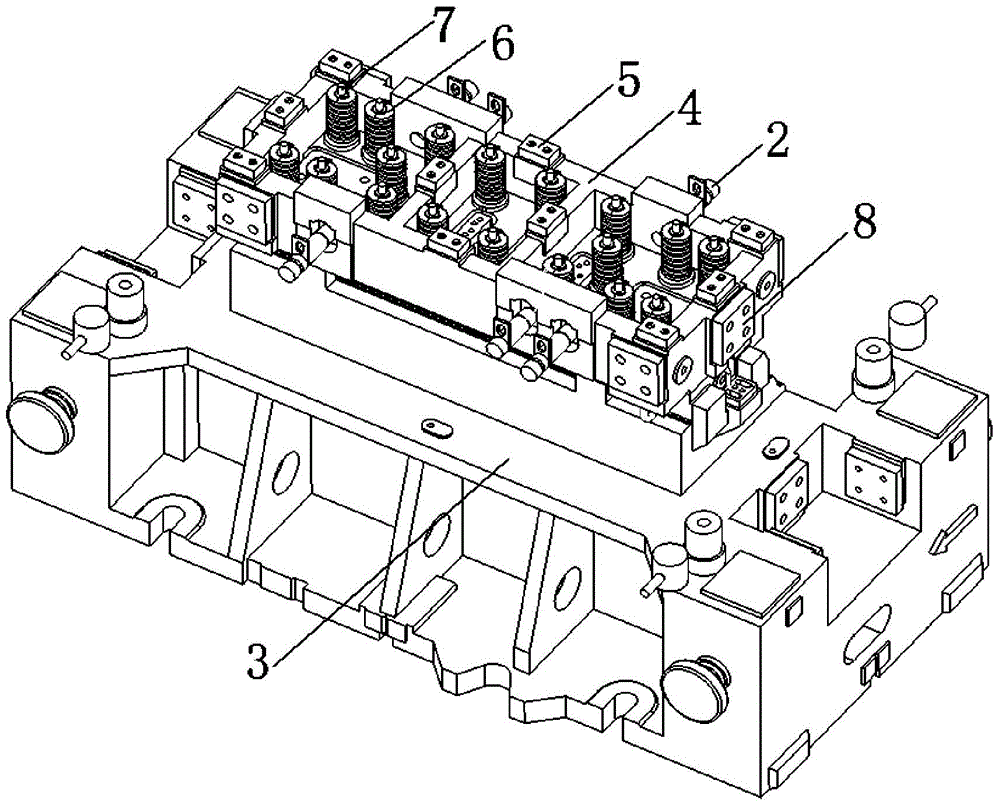

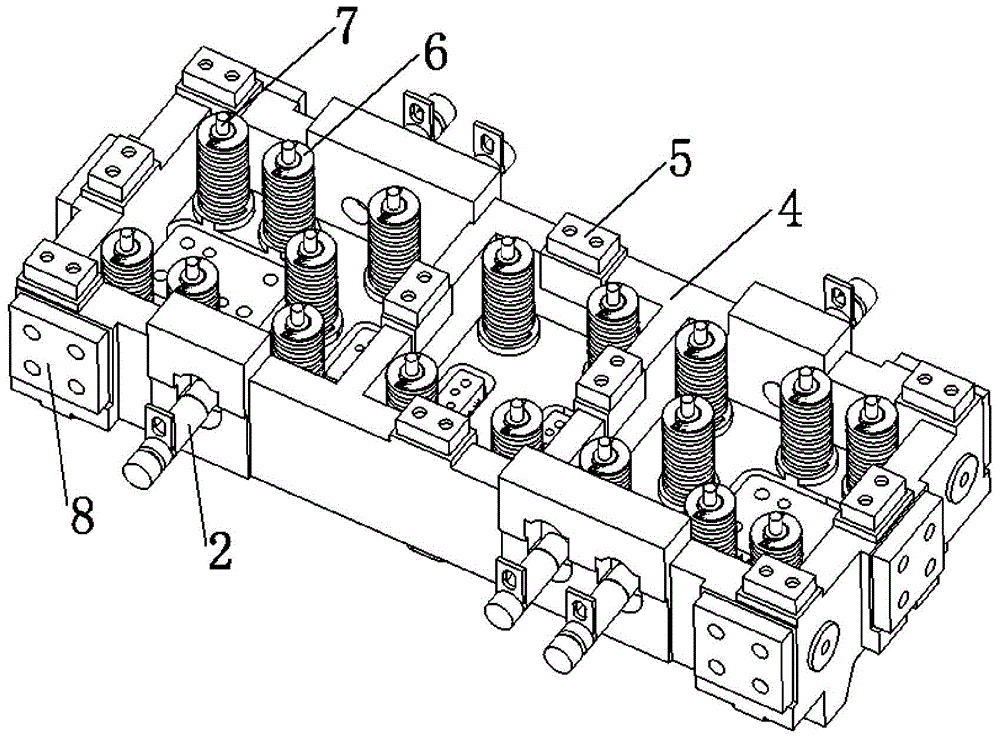

[0036] Such as Figure 5-9 As shown, the embodiment of the present invention provides an upper mold of a stamping die, the upper mold includes an upper mold base 11, an elastic element 12, a pilot pin 13, a mounting plate 14, a dowel bar 15 and a pressing core 16, wherein:

[0037] Upper mold base 11 can be an integral casting, and its bottom (the bottom refers to the side for installing elastic element 12 after upper mold base 11 has been manufactured) has a space for installing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com