A screening slag loading building

A slag loading and screening technology, which is applied in sieves, solids separation, grids, etc., can solve the problems of the quantity and quality of aggregates that cannot meet the requirements, the demand for sand and gravel aggregates is large, and the inability to screen aggregates, etc. To achieve the effect of easy promotion and use, simple structure and reduced mechanical input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

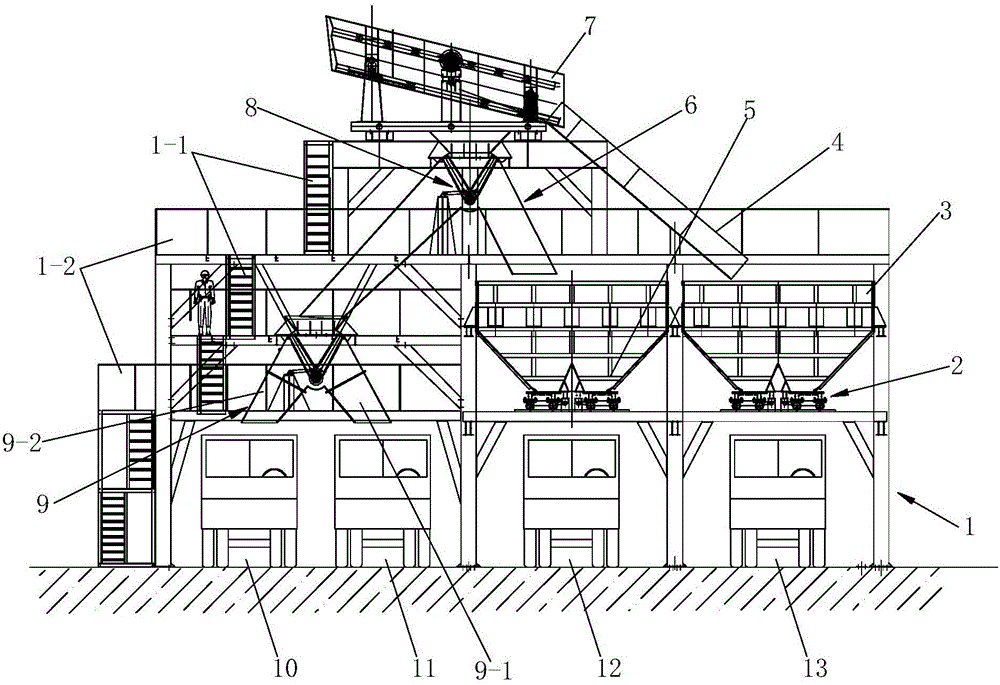

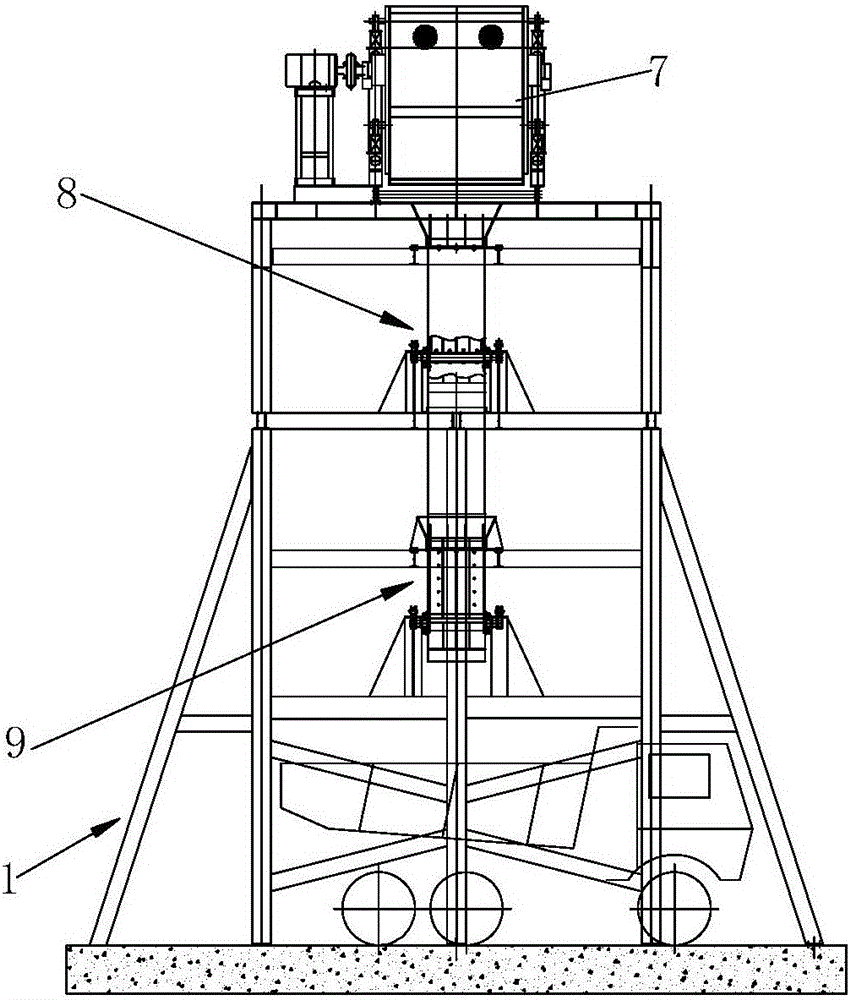

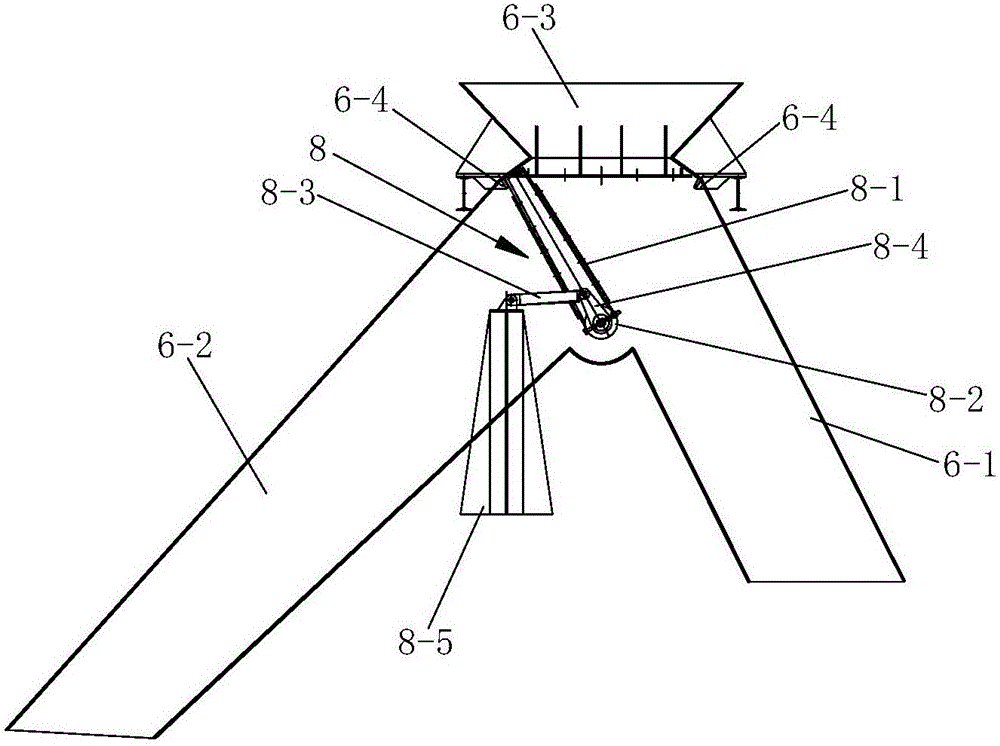

[0050] Such as Figure 1 to Figure 6A kind of screening slag loading building shown comprises vibrating screener 7, aggregate box 3, slag collecting box 5, first slag separator 6 and second slag separator 9; The aggregate outlet is connected to the aggregate box 3 through the first chute 4, and the spoil outlet of the vibrating screen 7 is connected to the feed inlet of the first slag separator 6; the first slag separator 6 includes The first slag separating cylinder 6-1 connected with the slag collecting box 5 and the second slag separating cylinder 6-2 connected with the feed port of the second slag separator 9; the second slag separator 9 includes For the third slag separator 9-1 and the fourth slag separator 9-2, which are charged to the transfer vehicle, the first slag separator 6 and the second slag separator 9 are provided with valves for controlling the flow direction of the waste slag. Switching device 8. In this embodiment, the vibrating screener 7 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com