Straw displacement device in seed ditches of corn resowing cornfields

A displacement device and seed ditch technology, applied in agricultural machinery and tools, agriculture, shovels, etc., can solve the problems of increasing wheat production costs, unfavorable soil fertilization, etc., and achieve difficult emergence, high operating efficiency, and improved drought and frost resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

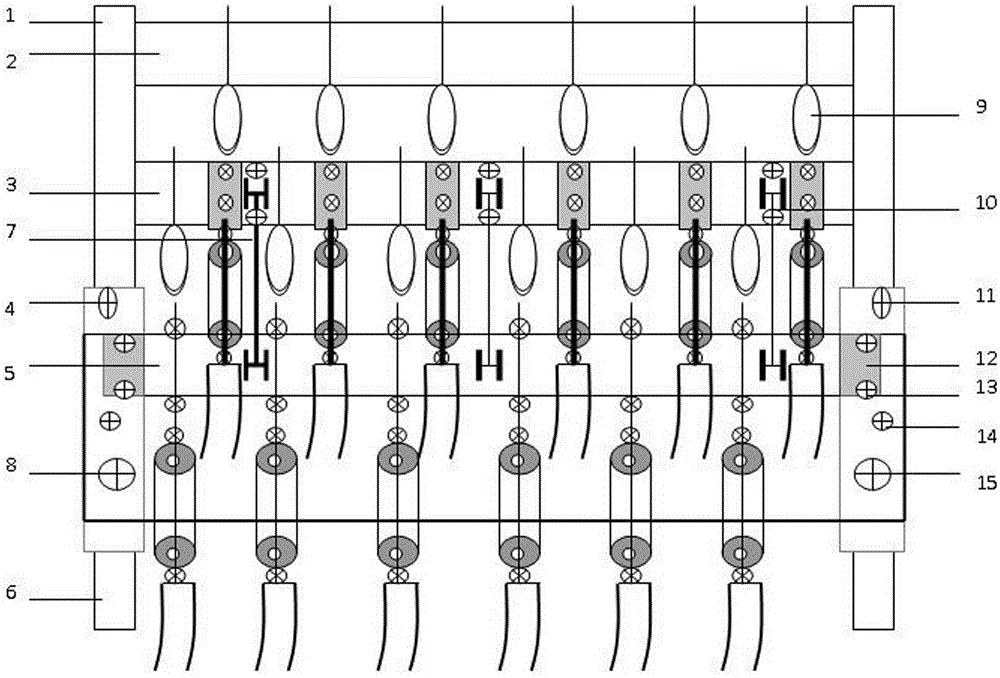

[0015] The support includes a crossbeam (5), a rear beam (3), two left and right longitudinal beams (4), and three struts (7). The bracket is located behind the rotary tiller and in front of the seeder. The front and rear ends of the longitudinal beam (4) are respectively fixed with the longitudinal beam of the rotary cultivator (6) and the longitudinal beam of the planter (1) by bolts E (15) and bolts B (11); the two ends of the bracket beam (5) They are respectively fixed with the left and right longitudinal beams (4) of the bracket through the backing plate A (12) and the bolt C (13); Fixed, the other end is welded on the support beam (5); the pedal (8) is fastened to the left and right ends of the support longitudinal beam (4) and fixed by bolt D (14). The rear beam (3) can be directly replaced by the front beam of the planter.

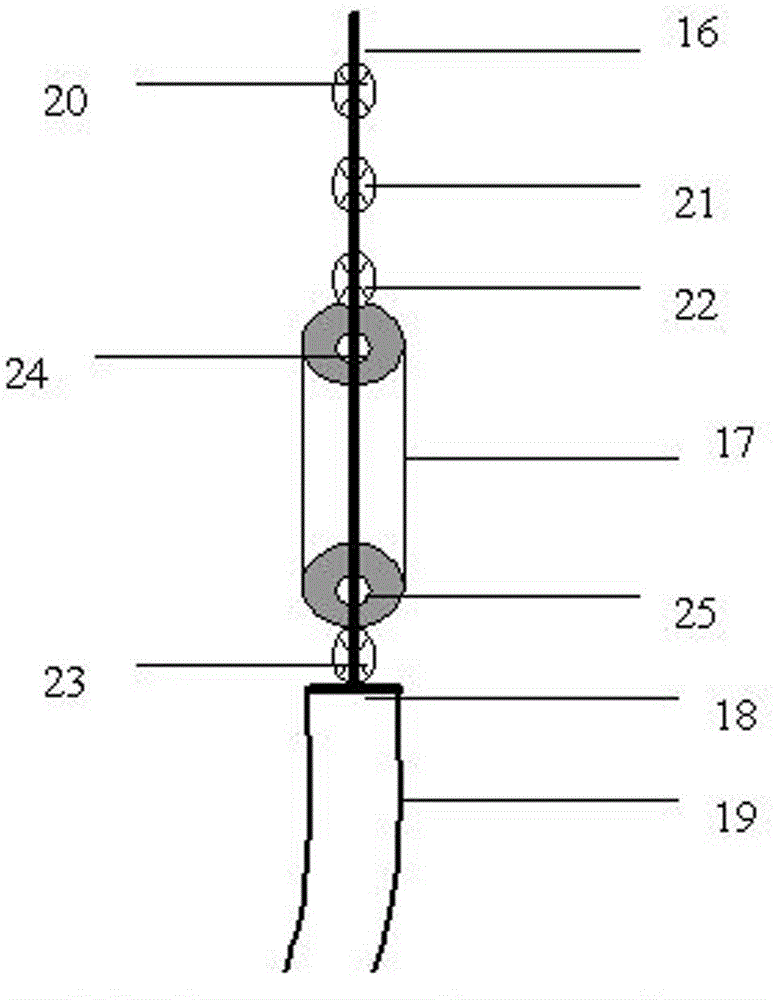

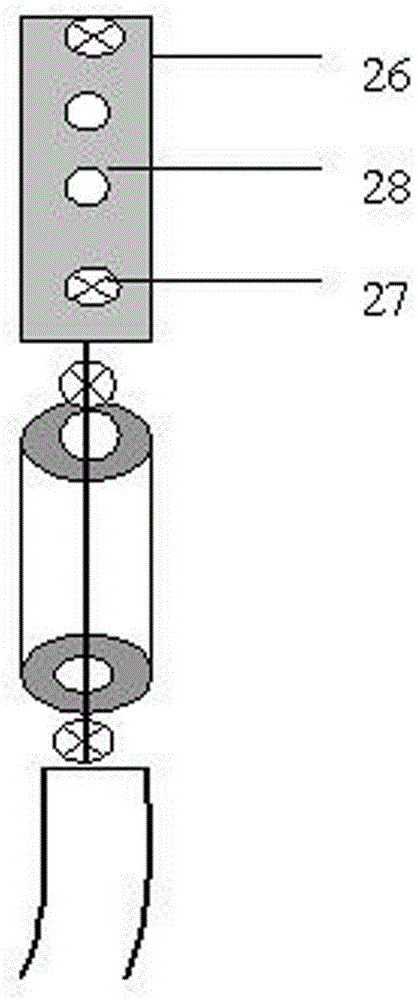

[0016] The stalk member is aligned longitudinally with the disc opener (9) of the planter. The stalk member installed on the support beam (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com