Matrix suction force control method for substrate dry-wet cycle test

A dry-wet cycle and matrix suction technology, which is applied in the field of geotechnical testing and the matrix suction control method of roadbed dry-wet cycle test, can solve the problems of chemical analysis method, such as many test steps, rough means, and difficult to operate, and achieves convenient use and manufacturing. Simple, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

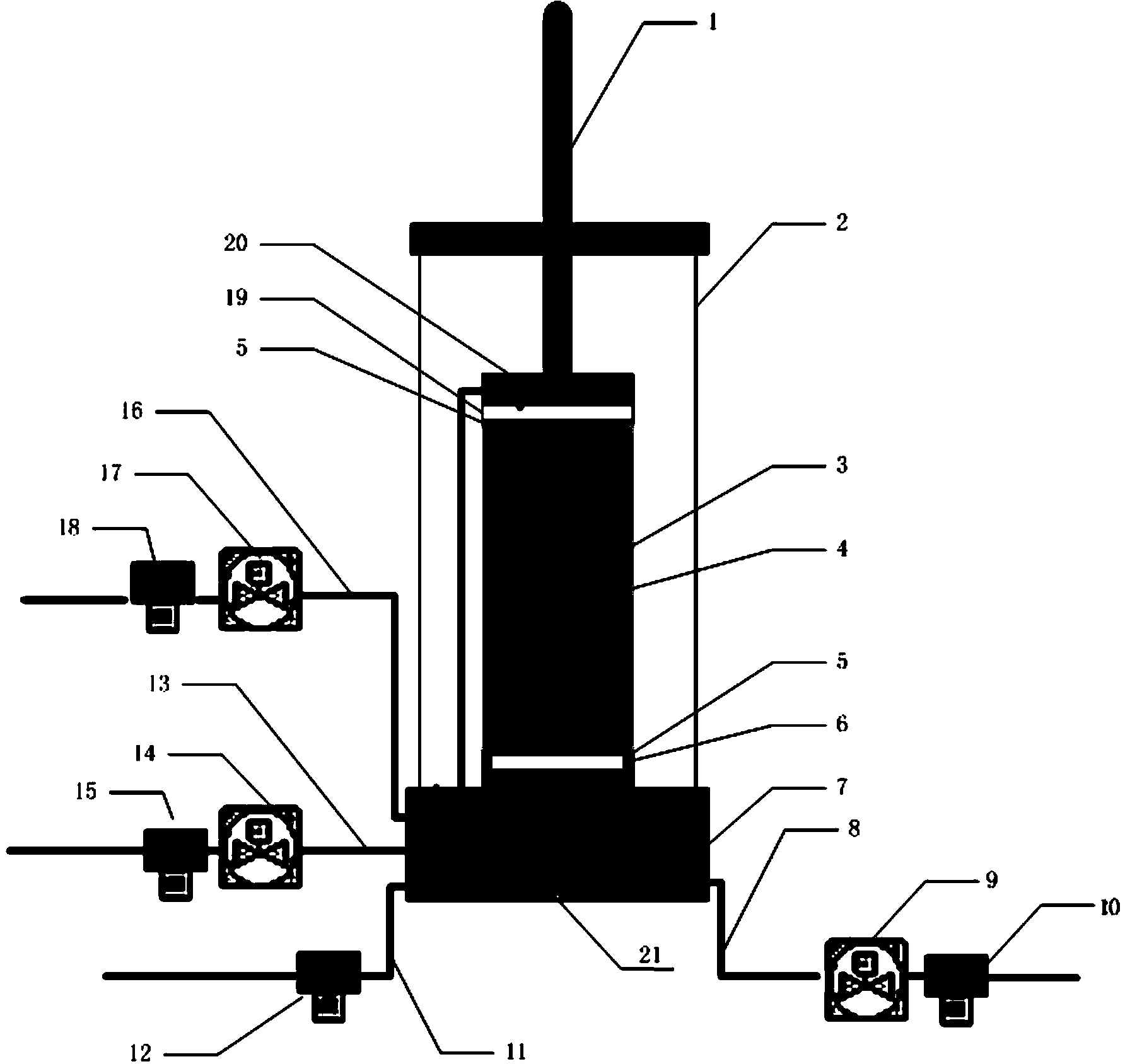

[0068] The dimensions of the apparatus used in the examples are as follows:

[0069] The length of the rubber film is 15-20cm, and the diameter is 5cm; the inner diameter of the pressure chamber cover is not less than 20cm, and the height is 30cm; the height of the lower part of the base of the sample device is 8cm, the diameter is 25cm, the upper part is 4cm, and the diameter is 5cm; the height of the upper cap of the sample is 2cm , 5cm in diameter; air pressure pipes, confining pressure pipes, and back pressure pipes use high-pressure water pipes (air pipes), air pressure pipes have a diameter of 6mm, and confining pressure pipes and back pressure pipes have a diameter of 8mm.

[0070] The soil sample used in the example is clay with a low liquid limit; through heavy-duty compaction tests, the optimal moisture content of the soil sample is 13.6%, and the maximum dry density is 1.82g / cm 3 . The test compaction degree is 94%, the target water content is 18%, and the saturate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com