Bolt-free fastener system for tramcar

A technology for trams without bolts, applied in the direction of tracks, track superstructures, roads, etc., to achieve the effects of preventing over-installation, improving stability, and increasing distance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

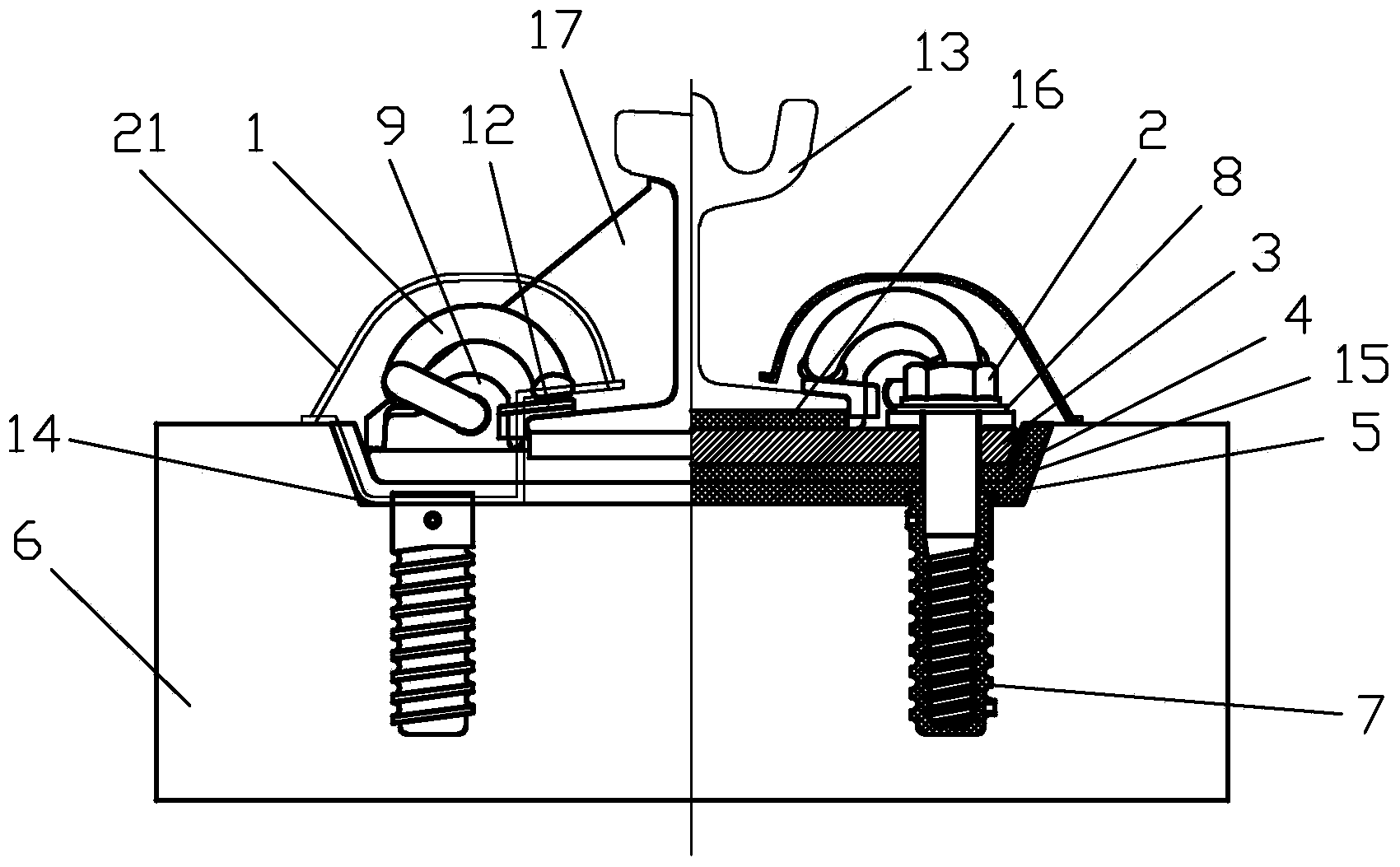

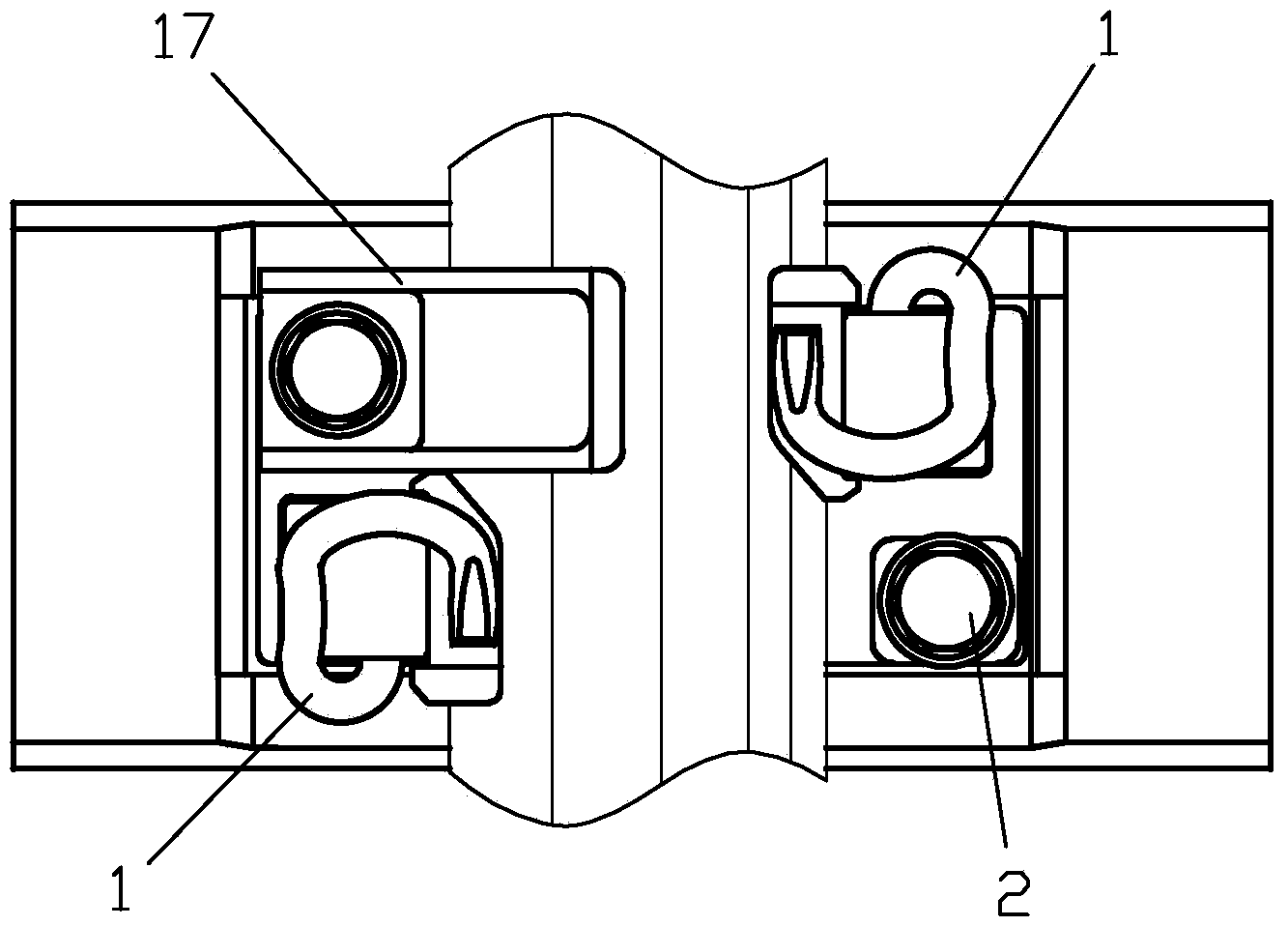

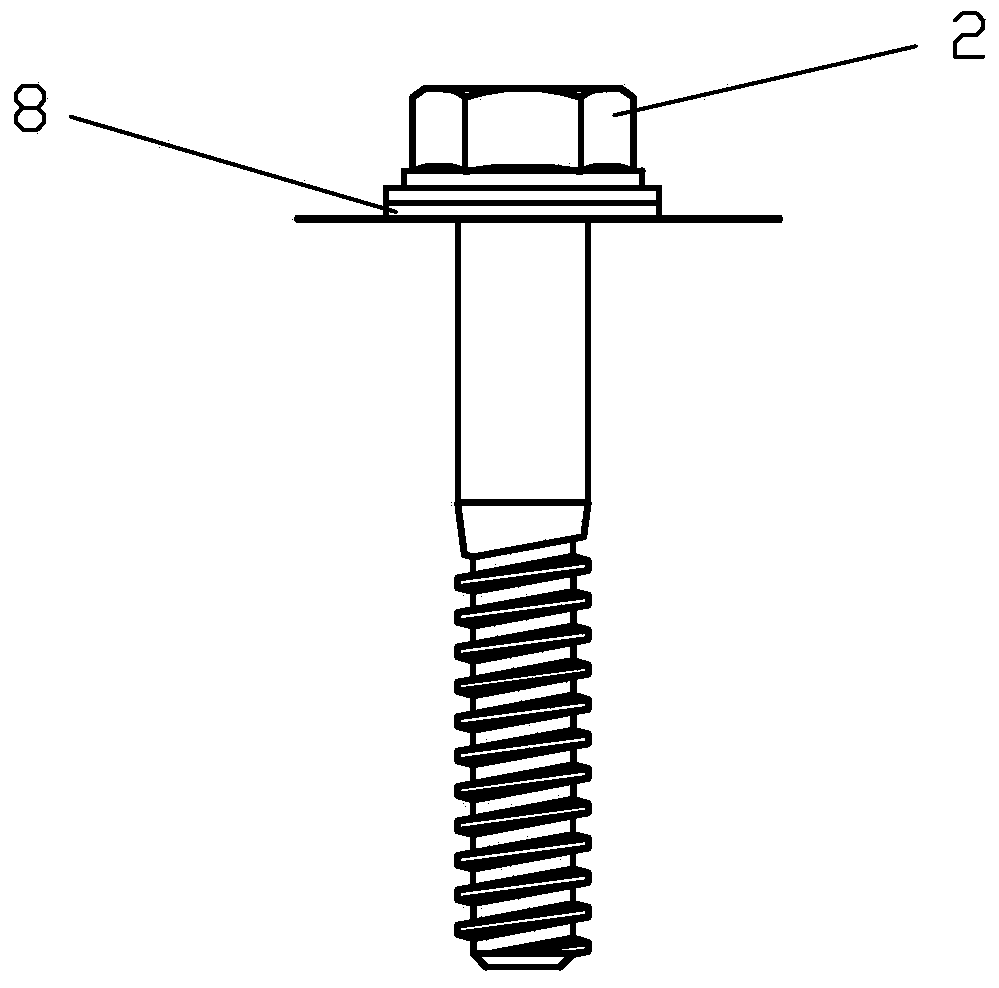

[0047] Such as figure 1 , 2 As shown, a boltless fastener system for a tram according to the present invention includes two e-shaped spring bars 1, two spiral spikes 2, an iron backing plate 3 for preventing the spring bars from being installed, and rails 13 on both sides An e-shaped spring bar 1 and a spiral spike 2 are arranged respectively, a height-adjusting backing plate 4 is laid under the iron backing plate 3, an elastic backing plate 5 is laid between the height-adjusting backing plate 4 and the sleeper 6, and rails on both sides of the rail 13 The e-shaped elastic bar 1 and the spiral spike 2 are arranged in a staggered manner. The spiral spike 2 passes through the iron backing plate 3 and is fixed to the sleeper 6. The sleeper 6 is equipped with a pre-embedded casing 7 corresponding to the spiral spike 2. Refer to image 3 , A double disc spring washer 8 is provided between the spiral spike 2 and the iron backing plate 3, which provides elasticity to the spiral spik...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated, and the difference is that:

[0058] refer to Figure 13 , Figure 14 , the fastener system of the present embodiment is not provided with a rail brace 17, which is used for general site use, and the position where the rail brace 17 contacts the iron backing plate 3 is not provided with serrated teeth 19 either.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com