A mobile suction cup lifting device

A hoisting device and suction cup technology, which is applied in hoisting devices, transportation and packaging, load hanging components, etc., can solve the problems of workpiece damage, difficult adjustment of hoisting position, and poor contact of hoisting devices, so as to avoid damage and realize large The effect of range movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

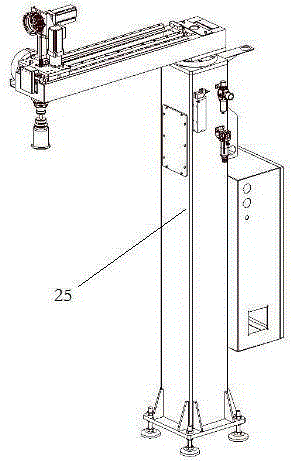

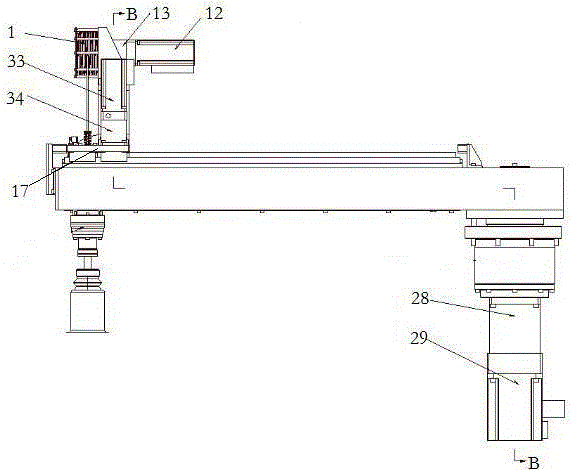

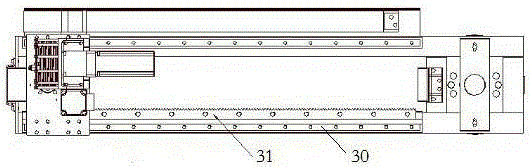

[0033] Example: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a movable suction cup lifting device includes a support frame 25, and the support frame 25 is provided with a rotating mechanism, a sliding mechanism and a suction cup lifting device. 14. The mounting base 14 is provided with a reel 1 wrapped with a wire rope, and the reel 1 is also provided with a wire rope anti-loosening shaft 15, and the first servo motor 12 is driven by a first planetary reducer 13 The winding drum 1 rotates, and the suction cup 11 is controlled by a vacuum generator 24 to generate a vacuum. The vacuum generator 24 is connected with a spiral telescopic air pipe 18. The vacuum generator 24 is arranged on the slide table 17, and the steel wire rope 16 passes through The guide hoisting device that keeps the suction cup vertically lifting is connected with the suction cup 11, and the spiral telescopic air pipe 18 is connected with the guide hoisting device.

[0034] The rotary me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com