Packaging robot for steel strip assembly line

A kind of assembly line and robot technology, applied in the direction of packaging, etc., can solve the problems of low production efficiency, unfavorable production development of enterprises, high labor cost, etc., achieve the effect of accurate packaging count, promote production development, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

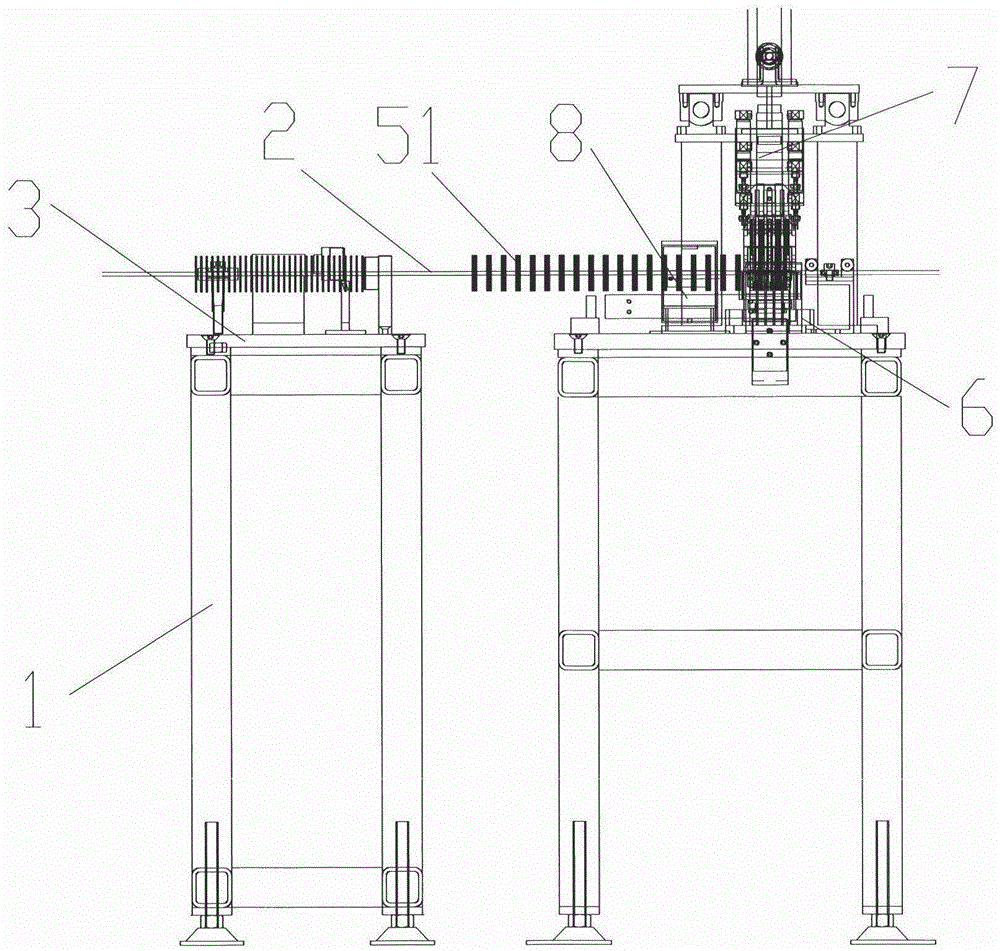

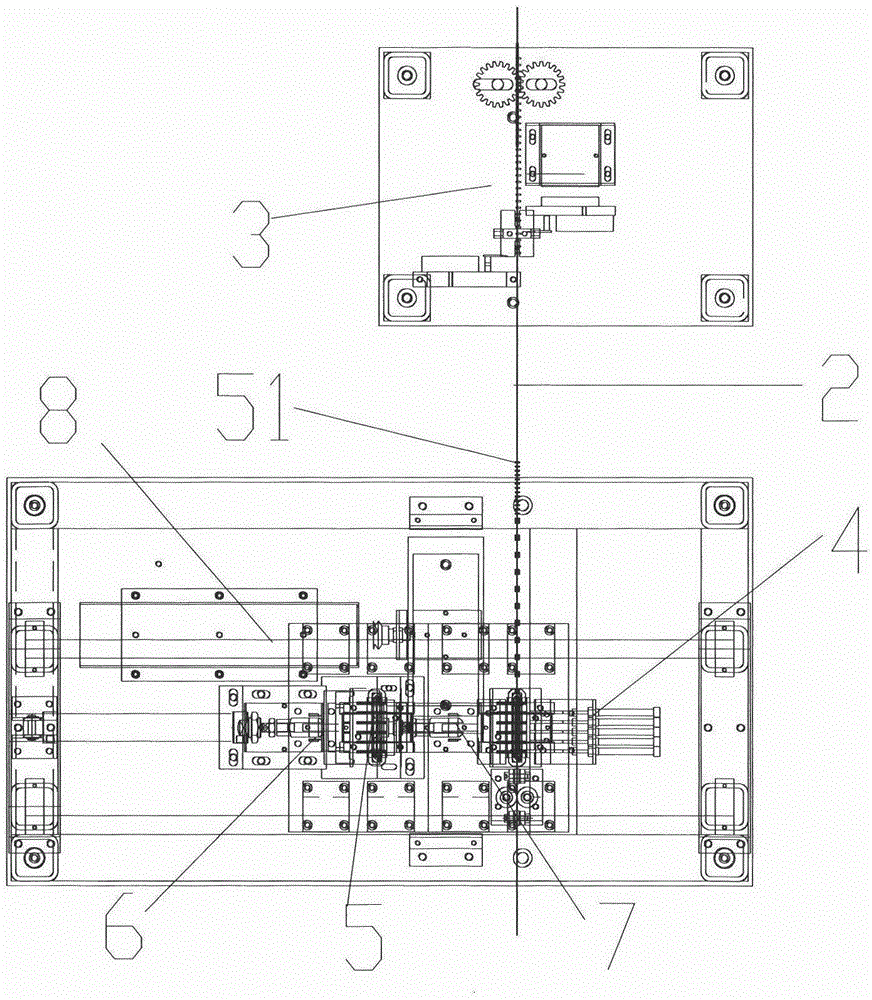

[0024] As shown in the accompanying drawings, a packaging robot for a steel strip assembly line of the present invention includes a frame 1 and a steel strip 2, and the steel strip 2 is arranged on the upper side of the frame 1 and traverses the frame 1; The frame 1 is successively provided with a counting and separating device 3, a queuing arrangement device 4, a bag taking device 5, a clamping device 6 and a grasping device 7; The adjacent position is provided with a bag box 8, and the bag taking device 5 can move back and forth between the bag box 8 and the clamping device 6; the grasping device 7 is arranged above the steel belt 2, and the The grabbing device 7 can move back and forth between the queuing sorting device 6 and the clamping device 6 .

[0025] The counting and separating device 3 includes a main board 9, a T-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com