Method and system for leveling chassis of vehicle

A chassis and vehicle technology, applied in the field of vehicle chassis leveling methods and systems, can solve problems such as low precision and easy occurrence of virtual legs, and achieve the effects of improving accuracy, avoiding virtual legs, and avoiding unleveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

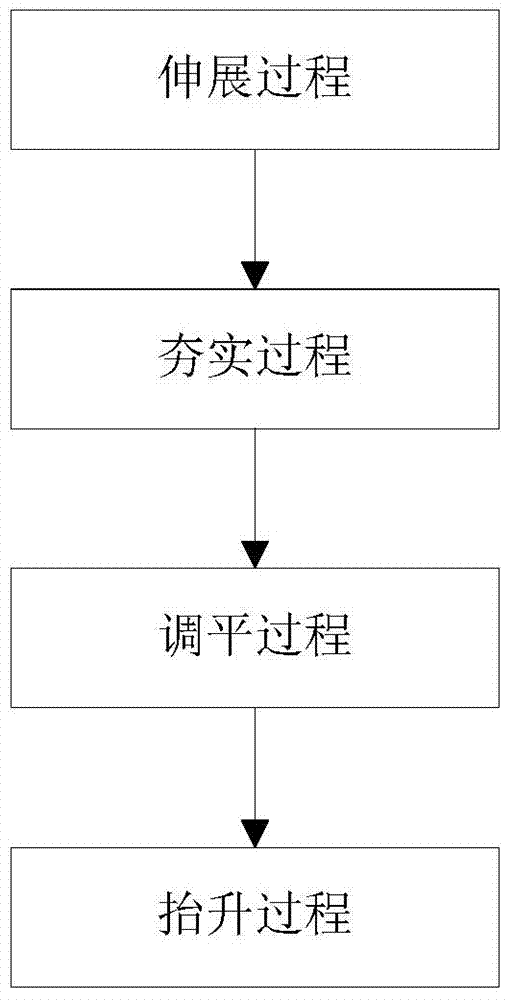

[0032]The vehicle chassis leveling method and system of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

[0033] refer to Figure 4 with Figure 5 , are respectively a structural schematic diagram and a schematic connection diagram of a preferred embodiment of the vehicle chassis leveling system of the present invention. In this preferred embodiment, the leveling system of the vehicle chassis of the present invention comprises:

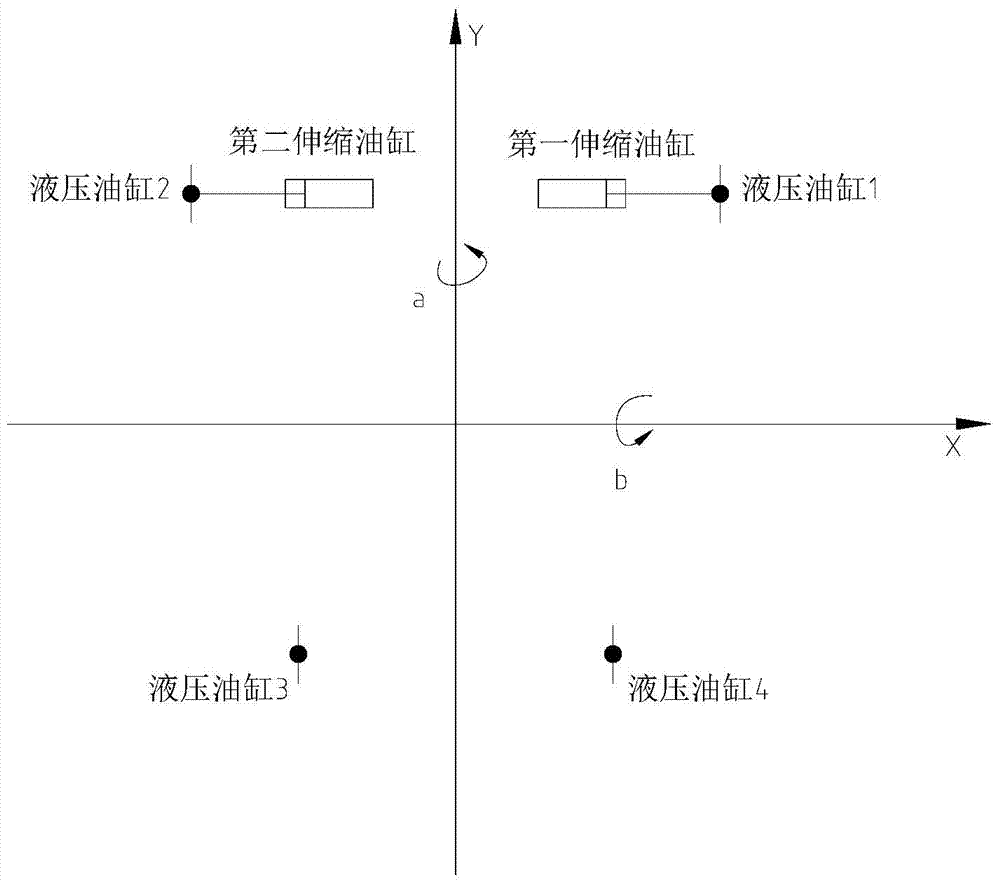

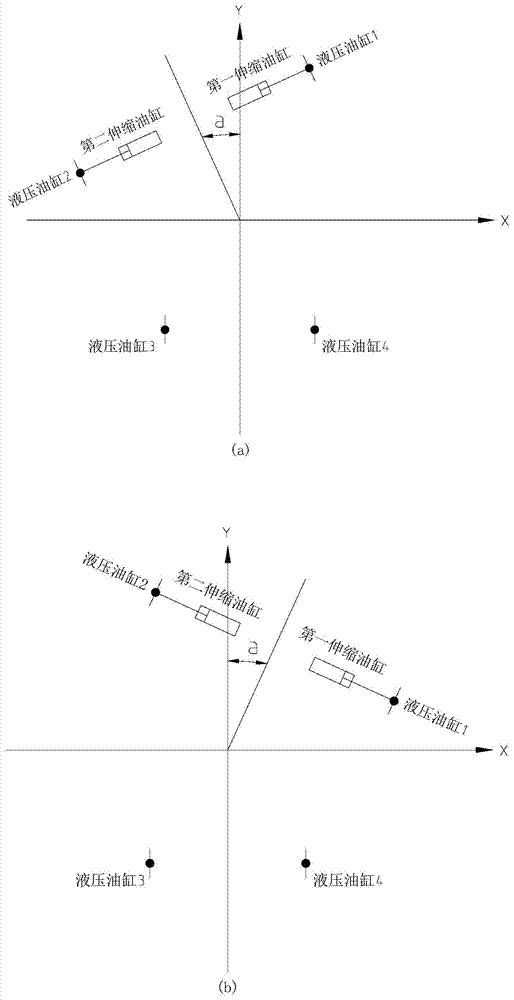

[0034] Hydraulic control system, four hydraulic oil cylinders C201~C204 corresponding to the outriggers, the first telescopic oil cylinder C205 and the second telescopic oil cylinder C206 that are symmetrically arranged on the front of the vehicle chassis and can be extended and retracted in the horizontal direction, fixedly arranged on the vehicle chassis for A two-axis level sensor that detects the tilt ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com