Detaching apparatus and detaching method

A peeling device, reference position technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve problems such as pattern damage, unstable boundary line shape, and peeling speed variation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

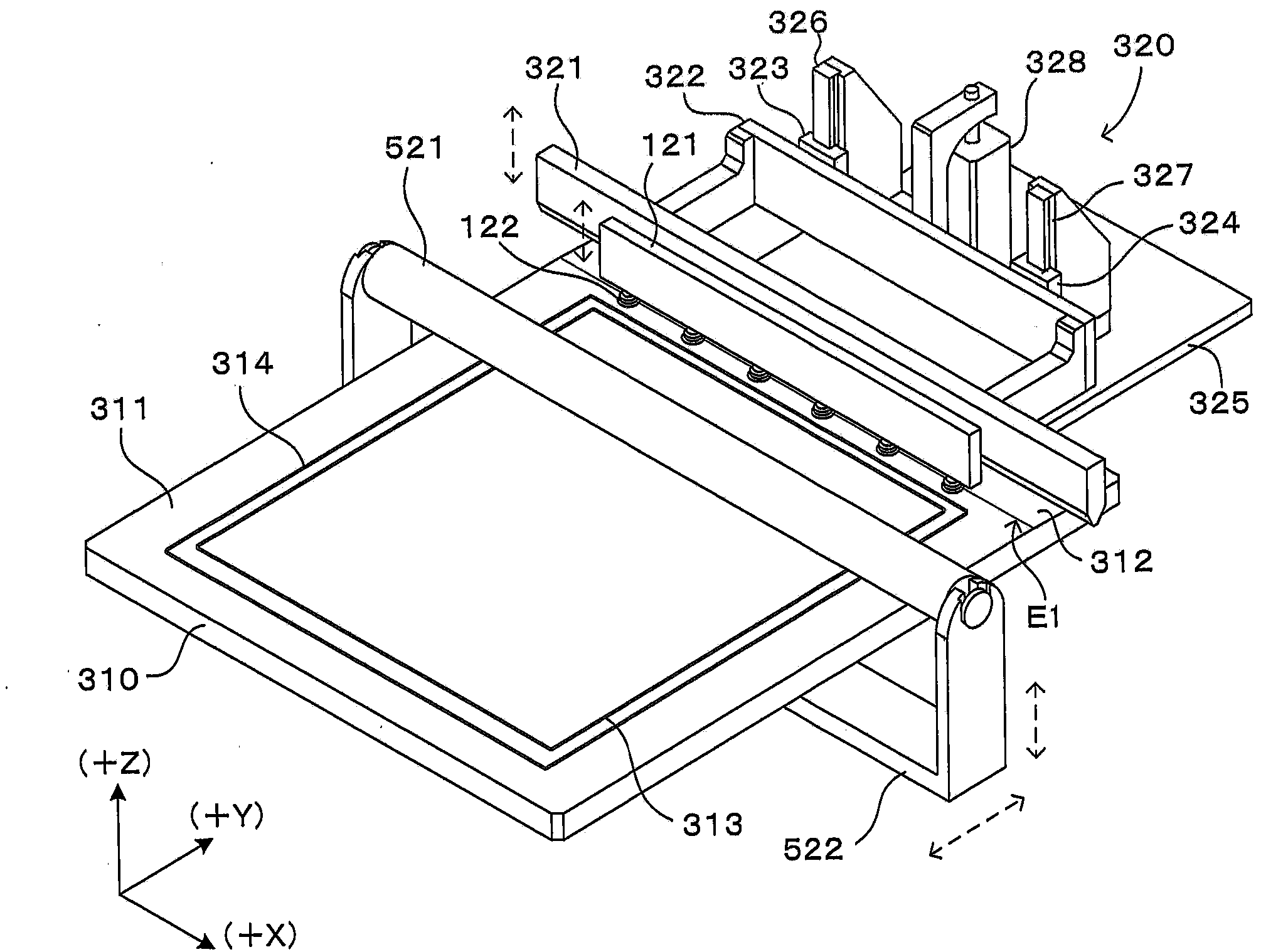

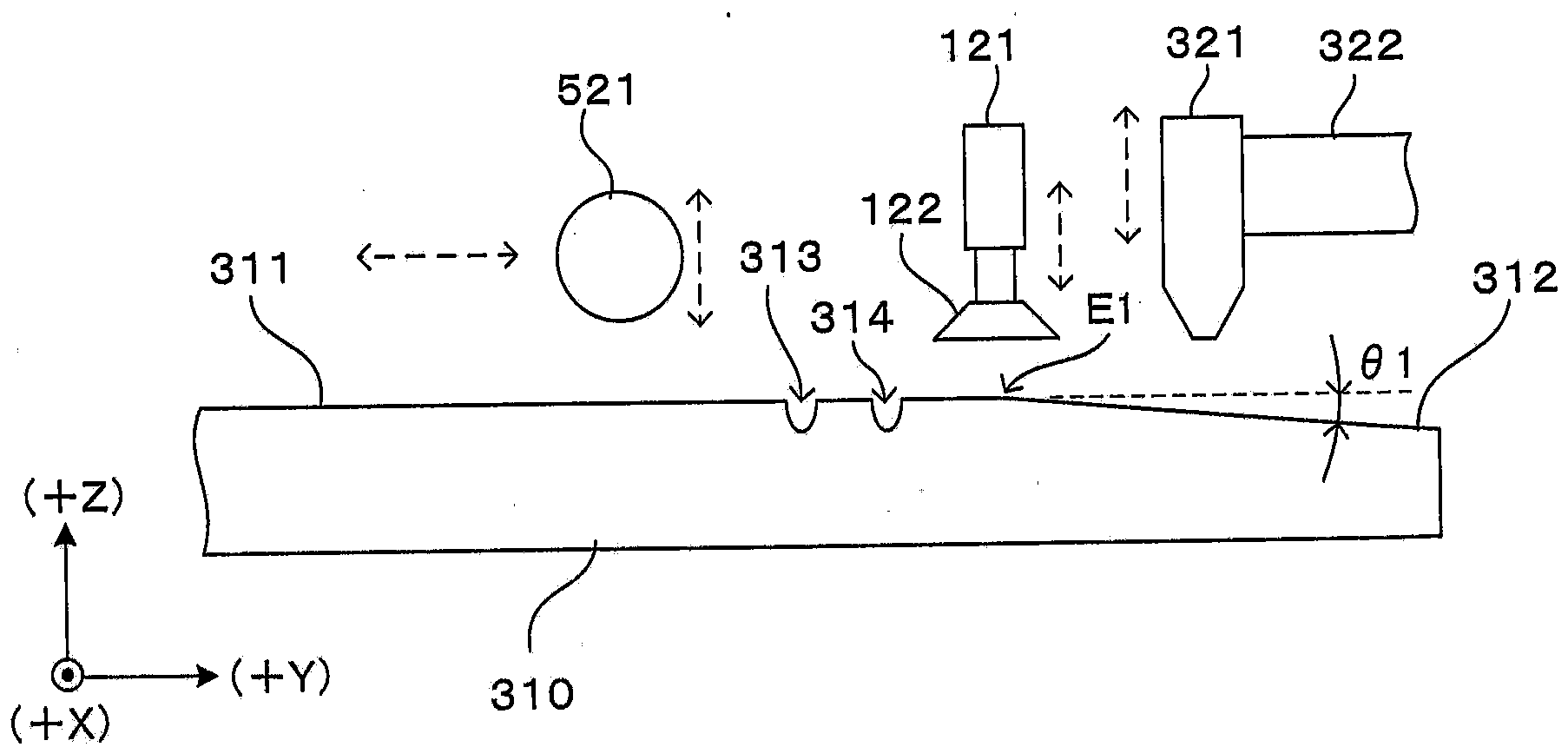

[0062] figure 1 It is a perspective view which shows 1st Embodiment of the peeling apparatus of this invention. In order to uniformly represent the directions in each figure, such as figure 1 Set the XYZ orthogonal coordinate axes as shown on the lower right. Here, the XY plane represents a horizontal plane, and the Z axis represents a vertical axis. More specifically, the +Z direction indicates a vertically upward direction. In addition, in each of the following figures, the size of each part may be appropriately enlarged or reduced to facilitate understanding of the invention. Therefore, in particular, the thicknesses of the substrates and blankets described later and the intervals between them may be shown larger than they actually are.

[0063] This peeling device 1 is a device for peeling two plate-shaped objects carried in with their main surfaces in close contact with each other. For example, it is used in a part of the pattern forming process of forming a predeter...

no. 2 approach

[0137] Figure 9 It is a perspective view which shows 2nd Embodiment of the peeling apparatus of this invention. In order to uniformly represent the directions in each figure, such as Figure 9 Set the XYZ orthogonal coordinate axes as shown on the lower right. Here, the XY plane represents a horizontal plane, and the Z axis represents a vertical axis. More specifically, the +Z direction indicates a vertically upward direction. In addition, in each of the following figures, the size of each part may be appropriately enlarged or reduced to facilitate understanding of the invention. Therefore, in particular, the thicknesses of the substrates and blankets described later and the intervals between them may be shown larger than they actually are.

[0138] With the stripping device 1 of the first embodiment ( figure 1 ) Similarly, this peeling device 2001 is a device for peeling two plate-shaped objects carried in with their main surfaces in close contact with each other. That...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com