Mold workshop scheduling method based on real-time production data collection

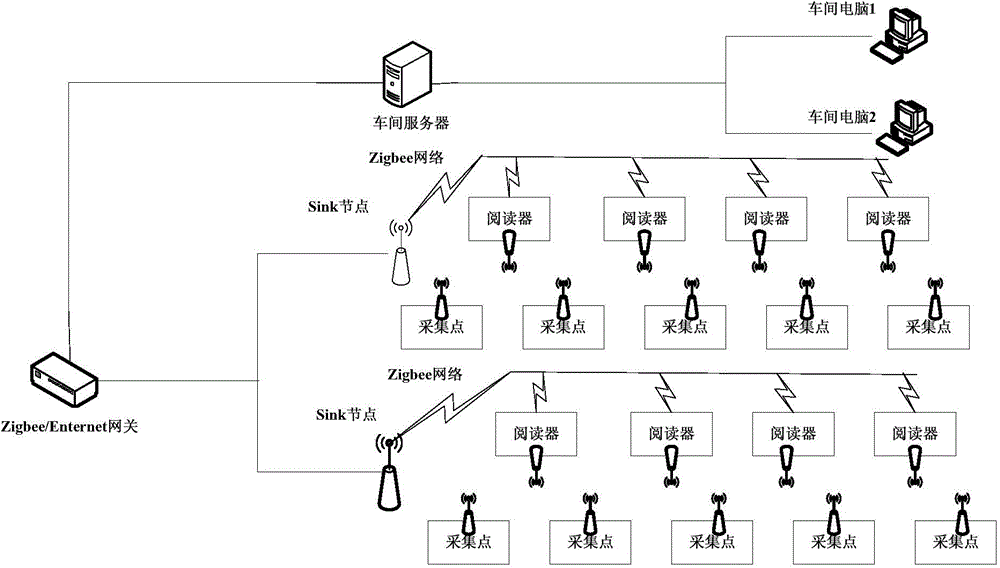

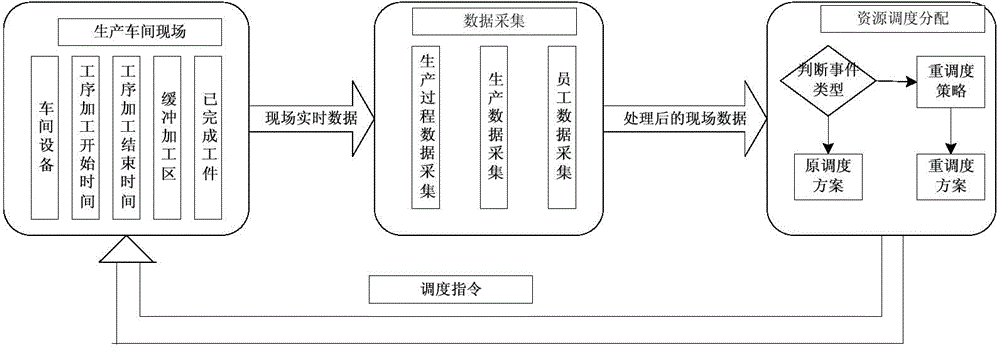

A technology for workshop scheduling and production data, which is applied in data processing applications, instruments, manufacturing computing systems, etc., and can solve problems such as accumulation, expansion, and inability to provide timely feedback of on-site interference information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

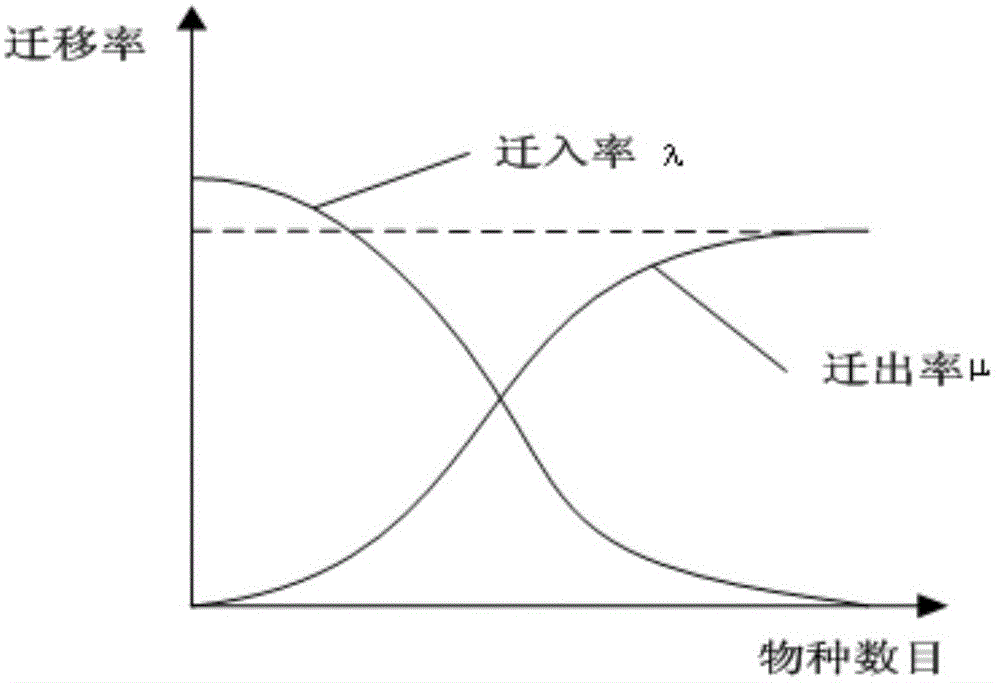

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0074] A mold workshop scheduling method based on real-time production data collection, its specific implementation is as follows:

[0075] Step 1. Determine the objective function for job scheduling in the die shop.

[0076] Mold manufacturing is characterized by different cycle lengths, different product types, and heavy tasks. Once an order is signed, meeting the delivery date required by the customer and minimizing production costs are the most important goals. Only in this way can the economic efficiency of the enterprise be improved. Therefore, the completion time F 1 Minimize and total production cost F 2 Minimize the factor as the objective function; where F 2 Including equipment processing costs, staff costs and raw material costs;

[0077] F 1 = min ( Σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com