Mixed potential type no based on sandblasting processed porous ysz substrate 2 Sensor and preparation method

A mixed potential type and sandblasting technology, which is applied in the direction of material electrochemical variables, can solve the problems of limited performance improvement and small modification area, and achieve multiple active sites, controllable roughness and surface area, and good thermal stability. and chemical stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

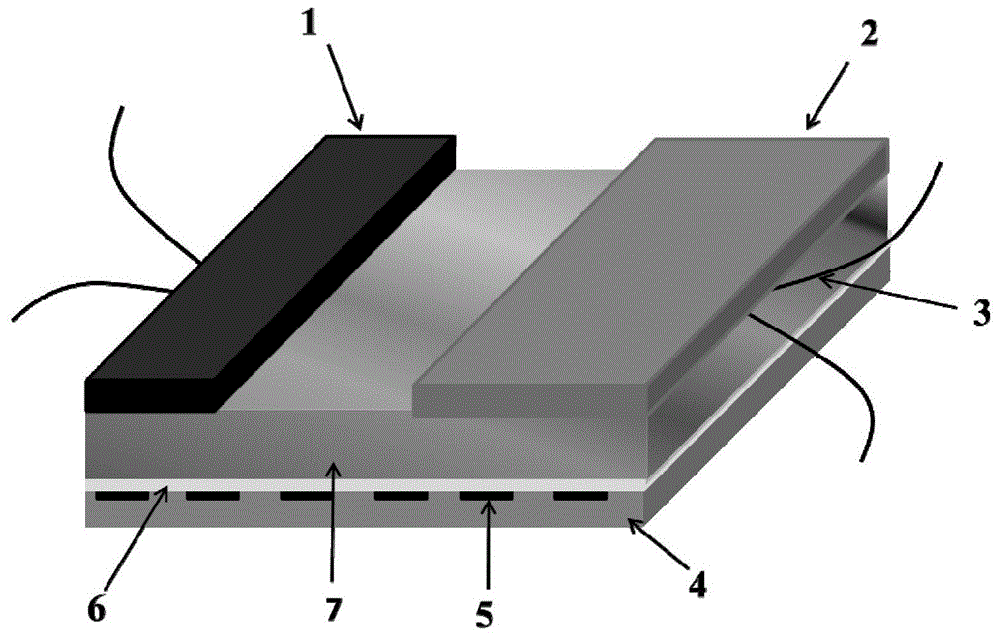

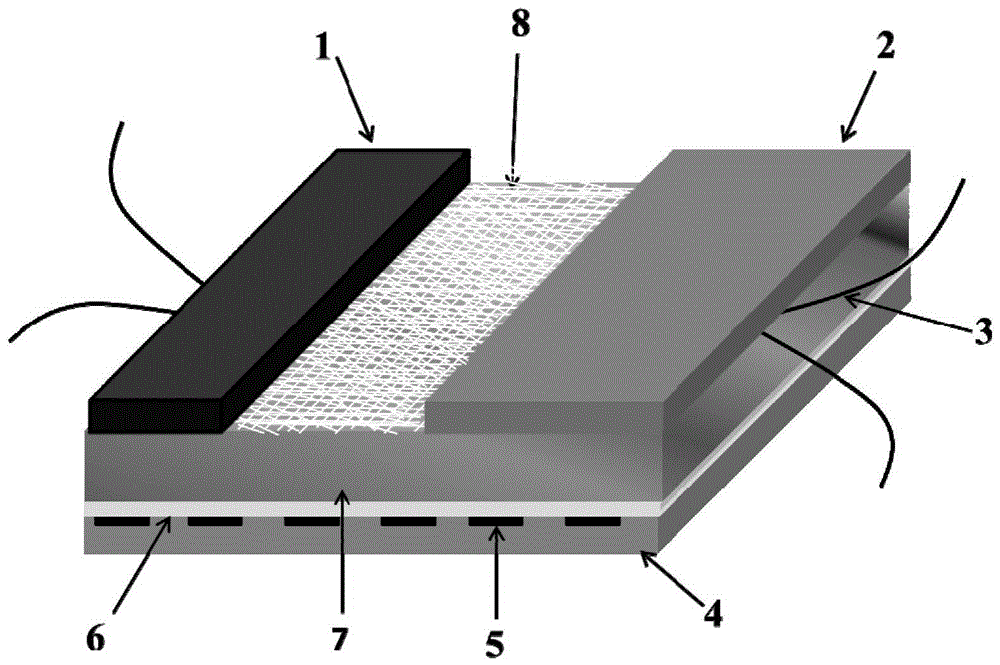

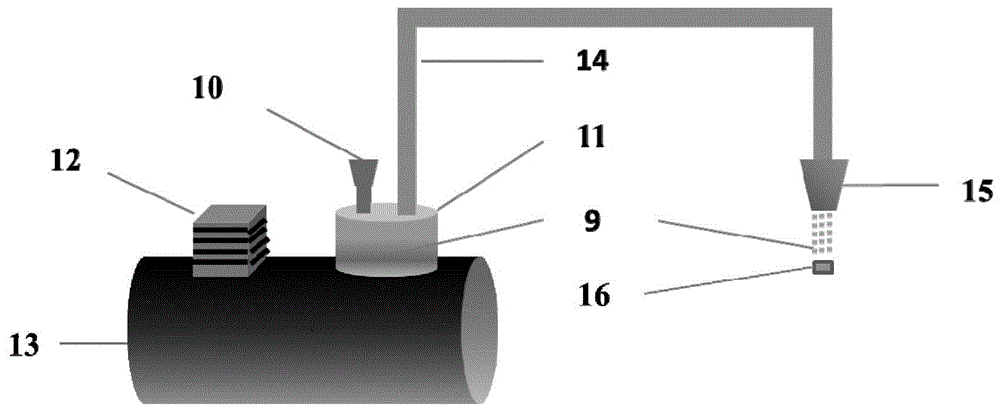

Method used

Image

Examples

Embodiment 1

[0054] Example 1: The YSZ substrate used in the sandblasting experiment, the sand particle size used is 40 μm, and the roughness is 364 nm.

[0055] The manufacturing process is to use the YSZ substrate with the roughness of 364nm processed by sandblasting to make the sensor device. Other manufacturing processes are the same as the comparative example.

[0056] Table 1 lists the devices made of unprocessed YSZ and sandblasted YSZ substrates with a roughness of 364nm at different concentrations of NO 2 The difference between the electromotive force in the atmosphere and the electromotive force in the air (ΔV) varies with NO 2 As for the change value of the concentration, it can be seen from the table that the sensitivity of the device made of the sandblasted YSZ substrate with a roughness of 364nm has some improvement, but the change is not much.

[0057] Table 1. ΔV vs. NO 2 change in concentration

[0058]

Embodiment 2

[0059] Example 2: The YSZ substrate used in the sandblasting experiment has a sandblasting particle size of 60 μm and a roughness of 649 nm.

[0060] The manufacturing process is to use YSZ with a roughness of 649 nm as a substrate to manufacture a sensing device by sandblasting. Other manufacturing processes are the same as the comparative example.

[0061] Table 2 lists the devices made of unprocessed YSZ and sandblasted YSZ substrates with a roughness of 649nm at different concentrations of NO 2 The difference between the electromotive force in the atmosphere and the electromotive force in the air (ΔV) varies with NO 2 It can be seen from the table that the sensitivity of the device made of the YSZ substrate with a roughness of 649nm after sandblasting has been greatly improved.

[0062] Table 2. ΔV vs. NO 2 change in concentration

[0063]

[0064]

Embodiment 3

[0065] Example 3: The YSZ substrate used in the sandblasting experiment has a sandblasting particle size of 80 μm and a roughness of 775 nm.

[0066] The manufacturing process is to use YSZ with a roughness of 775nm sandblasting as a substrate to make a sensing device. Other manufacturing processes are the same as the comparative example.

[0067] Table 3 lists the devices made of unprocessed YSZ and sandblasted YSZ substrates with a roughness of 775nm at different concentrations of NO 2 The difference between the electromotive force in the atmosphere and the electromotive force in the air (ΔV) varies with NO 2 It can be seen from the table that the sensitivity of the device made of the YSZ substrate with a roughness of 775nm after sandblasting has the best improvement.

[0068] Table 3. ΔV vs. NO 2 change in concentration

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com