Online quality detection system for printed matter

A detection system and printed matter technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of large waste and defective products, achieve the effect of reducing material waste, reducing labor demand, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

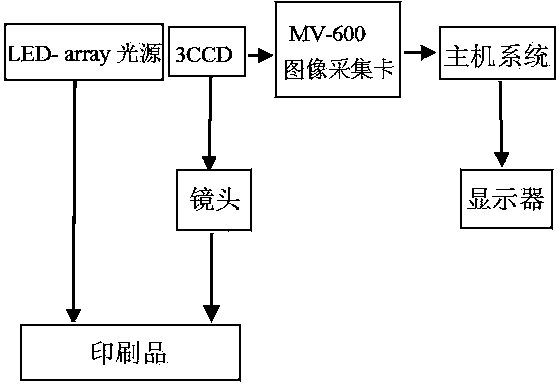

[0018] An online quality inspection system for printed matter, the system is composed of 3CCD camera, LED-array light source, zoom lens, MV-600 high-speed / high-precision industrial image acquisition card, PC platform hardware and image processing software.

[0019] This system uses 3CCD cameras instead of human eyes to take pictures. Specific features: (1) Definition: CCD (Charge Coupled Device, Change Coupled Device) is a semiconductor device that can convert optical images into digital signals. 3CCD, as the name suggests, is a camera using three CCDs. (2) Composition and function: CCD is composed of one or more cameras and lenses, and this system is composed of two cameras and lenses, which are used to shoot the printed matter to be tested. 3CCD uses 3 CCDs to convert red, green, and blue signals respectively, and the captured images are more natural in terms of color reproduction than single-chip CCDs, and their brightness and clarity are also better than single-chip CCDs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com