A combined adjusting pin shaft

A technology for adjusting pins and tapered surfaces, applied to pins, connecting components, mechanical equipment, etc., can solve the problems of increasing the frictional resistance of the pin shaft, large equipment damage, and long maintenance period, so as to increase the matching clearance and facilitate disassembly. , The effect of reducing the disassembly resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

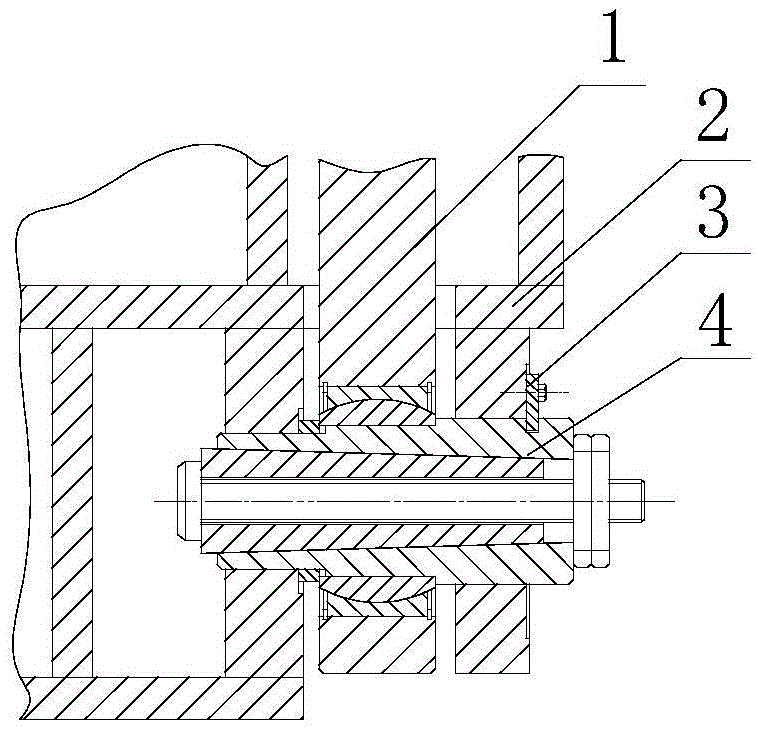

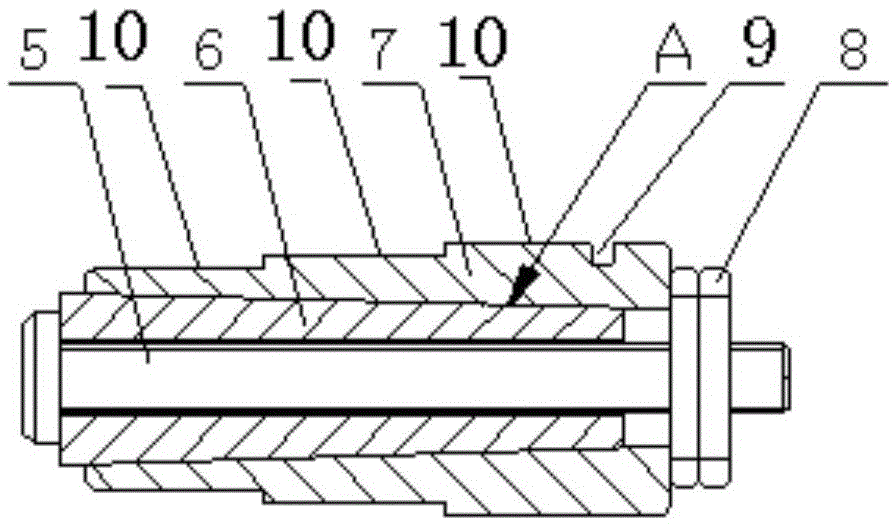

[0010] The present invention is described in detail below in conjunction with accompanying drawing.

[0011] refer to figure 1 , figure 2 , a combined adjustment pin shaft, including an outer shaft 7, the outer surface of the outer shaft 7 is provided with a positioning step 10, the outer shaft 7 is designed with a matching step and a shaft diameter with different matching requirements according to the matching requirements of the pin shaft, the outer shaft 7 and the inner shaft The 6 are radially matched through the tapered surface A, and the outer shaft 7 is longitudinally opened with a groove 9 with a width of 2-4mm. The other end is screwed with the nut 8, and the left end surface of the nut 8 is close to the small end surface of the tapered surface of the outer shaft 7.

[0012] Working principle of the present invention is:

[0013] refer to figure 1 , the combined pin shaft 4 of the present invention, the joint bearing on the connecting rod 1 and the sector frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com