Steep dip medium-thickness coal seam coal-mining device and mechanical method

A technology of coal mining device and steep inclination is applied in the field of coal mining device of steep incline medium and thick coal seam, which can solve the problems of low recovery rate, low coal mining efficiency, high labor intensity, etc., so as to improve coal mining efficiency and recovery rate, reduce The effect of coal mining labor intensity and high coal seam recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

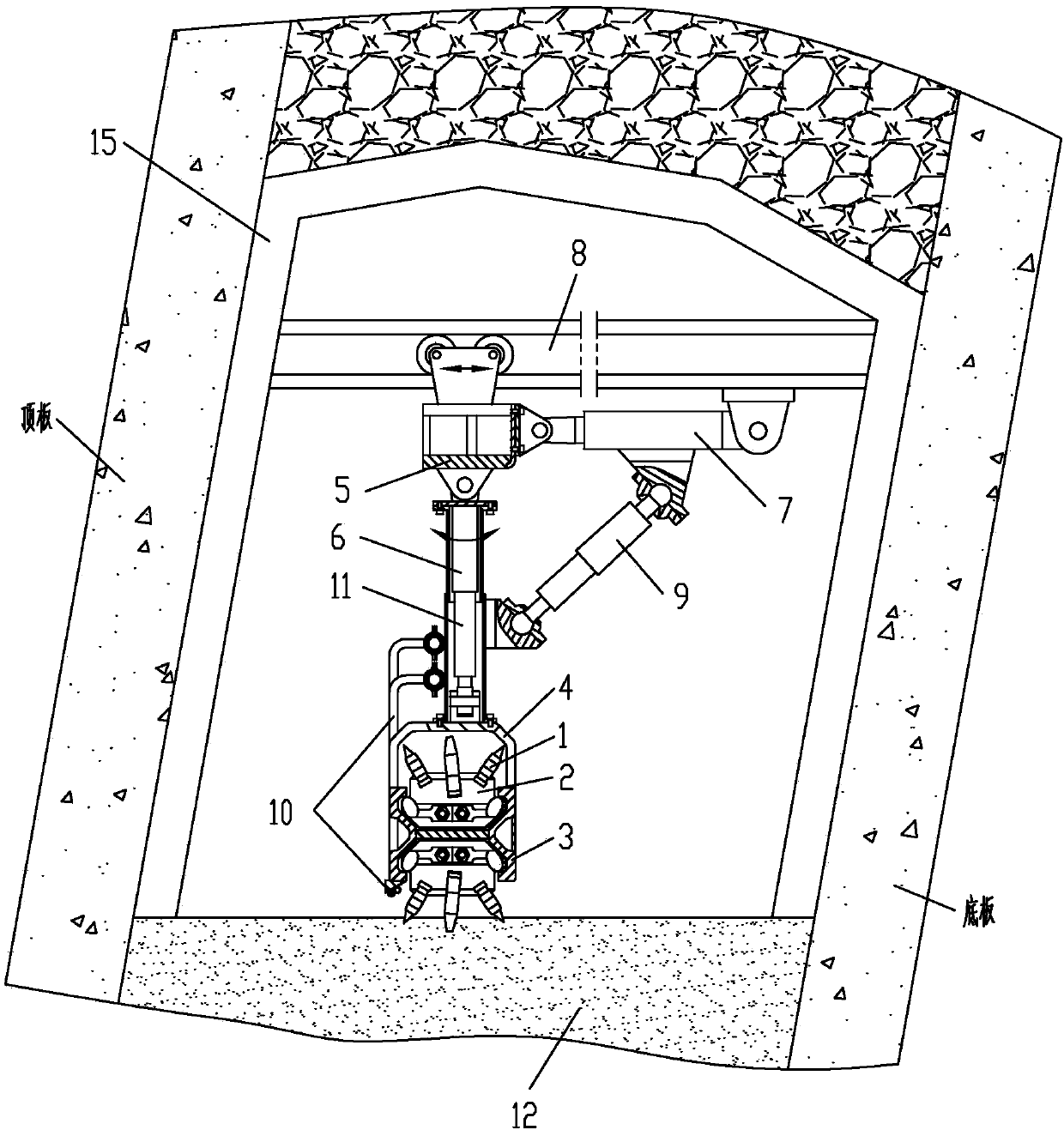

[0035] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , a coal mining device for steeply inclined medium-thick coal seams, comprising an integrated coal mining and transporting machine, a hydraulic system, and a control system. The coal cutting tooth 1 on the conveying scraper 2, the conveying scraper 2 drives its circular movement through the annular traction chain, and the coal mining and transportation integrated machine is fixedly connected with the gantry hanger 4 through the upper ends of both sides of the frame 3, the Above the hanger 4, there are a plurality of crossbeams 8 arranged in parallel in an I-shaped steel structure, and a moving part 5 is slidably connected to each crossbeam 8, and the moving part 5 is suspended by rollers supported on both sides of the I-shaped rail of the crossbeam 8 by rolling. On the beam 8; the lower part of the moving part 5 is hinged with a vertically arranged feed cylinder 6; a plurality of moving parts 5 are coaxial wi...

Embodiment 2

[0038] Example 2, see figure 1 , figure 2 , image 3 , Figure 4 , a method of mechanized coal mining in steeply inclined medium-thick coal seams, comprising the following steps:

[0039] In the first step, an opening is formed at the upper end of the steeply inclined coal seam 12, and a return airway 13 and a coal dropout 14 communicated with the transport roadway are respectively excavated downward along the inclined direction of the steeply inclined coal seam 12 at both ends of the cutout;

[0040] In the second step, set up a shield bracket 15 to control the roof in the cut hole, and fix the coal mining device of the first embodiment of the present invention on the shield bracket 15 through its plurality of beams 8, so that the mining and transportation of coal in the coal mining device The all-in-one machine is suspended above the top of the coal seam, and the all-in-one coal mining and transporting machine is adjusted to the initial state of leaning to the coal mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com