A device for recovering and recycling electroplating spray cleaning liquid

A technology of spraying cleaning and rinsing liquid, applied in electrolysis process, electrolysis components, cells, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

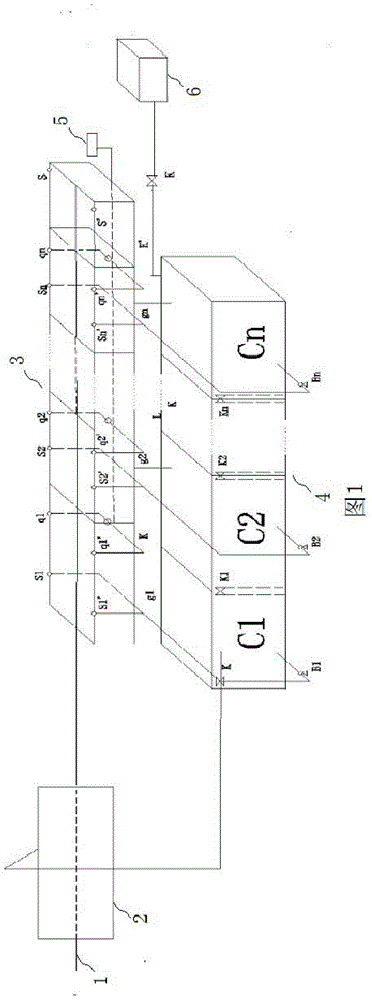

[0019] Such as figure 1 As shown, a device for recycling and reusing electroplating spray cleaning liquid of the present invention includes several circulating cleaning systems 3 set up along the production line 1, and the circulating cleaning systems are cascaded in series along the production line, and the number of the circulating cleaning systems is as follows: 5-30 is excellent. The plated parts are automatically moved from left to right on the automatic production line, and the pre-treatment, electroplating, cleaning, post-treatment and other processes are completed while moving to complete the entire electroplating process. The plated piece moves from the left side to the right side of the plating tank 2 while electroplating to the right side of the plating tank, and then the electroplating is completed and the tank enters the cleaning process.

[0020] The circulating cleaning system described here includes a spray cleaning tank, a nozzle and a pump, the nozzle is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com