Solid-phase resin and its preparation method and use

A technology of resin and peptide resin, which is applied in the field of peptide solid-phase synthesis, can solve the problems of high cost and unfavorable large-scale production of PEG king resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Resin preparation method

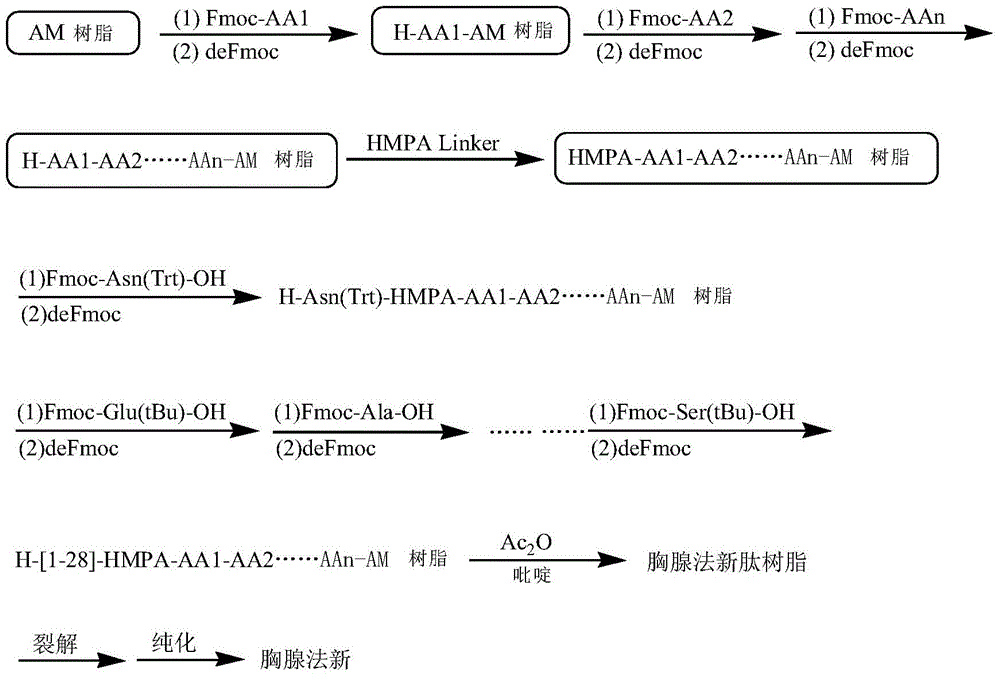

[0060] The above-mentioned specific resin that connects an amino acid or a small peptide in the HMPA Linker and AM resin provided by the present invention can be obtained by polypeptide solid-phase synthesis. Specifically, the following steps may be included:

[0061] Step 1. Obtain peptide resin fragments by peptide solid-phase synthesis: AA 1 -AA 2 ...AA n - AM resin;

[0062] Step 2. Connect HMPA Linker to get HMPA-AA 1 -AA 2 ...AA n - AM resin.

[0063] The condensing agent used in the above step 2 is preferably DIC / HOBt.

[0064] The use of resin - a new preparation method of thymus method

[0065] The above-mentioned specific resin that connects an amino acid or a small peptide in the HMPA Linker and AM resin provided by the present invention can be used for the new solid-phase synthesis of polypeptides by thymus method.

[0066] The preparation method of the thymus method new polypeptide solid-phase synthesis provided by the i...

Embodiment 1

[0098] H-[Arg(Pbf)] 4 -Synthesis of AM resin

[0099] (1) AM resin (manufactured by Tianjin Nankai Hecheng Technology Co., Ltd., with a substitution degree of 1.1mmol / g, 100g) was put into a solid-phase reaction column, washed twice with DMF, and swelled in DMF for 30 minutes.

[0100] (2) Dissolve Fmoc-Arg(Pbf)-OH (142.73g) and HOBt (44.58g) in DMF (800mL), add DIPCDI (69mL), and pre-react in an ice bath for 10 minutes.

[0101] (3) Add the above reaction solution into a solid-phase reaction kettle, stir it mechanically, and react at room temperature for 3 hours. The ninhydrin test shows that the resin is colorless and transparent.

[0102] (4) Drain the solution and wash 3 times with DMF. Use 20% piperidine in DMF to remove Fmoc twice at room temperature for 10 min and 20 min respectively.

[0103] (5) The solution was drained, the resin was washed 5 times with DMF and 2 times with DCM, and the ninhydrin test was positive.

[0104] (6) Repeat step (2) to step (5) to obta...

Embodiment 2

[0106] H-Asn(Trt)-HMPA-[Arg(Pbf)] 4 -Synthesis of AM resin

[0107] (1) Dissolve HMPA Linker (40.08g) and HOBt (44.58g) in DMF (800mL), add DIPCDI (69ml), and pre-react in an ice bath for 10 minutes.

[0108] (2) The above reaction solution was added to a solid-phase reaction column, stirred mechanically, and reacted at room temperature for 3 hours, and detected by ninhydrin, the resin was colorless and transparent. The solution was drained, and the resin was washed 3 times with DMF.

[0109] (3) Dissolve Fmoc-Asn(Trt)-OH (131.27g), HOBt (44.58g), and DMAP (2.69g) in DMF (6L), add DIPCDI (69ml), and pre-react in an ice bath for 10 minutes .

[0110] (4) The above reaction solution was added to a solid-phase reaction column, stirred mechanically, and reacted at room temperature for 3 hours. Drain the solution, wash the resin 3 times with DMF, and shrink with methanol.

[0111] (5) Block with resin for 2 hours, and the blocking solution is DMF / acetic anhydride / pyridine=1L / 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com