Auxiliary obstacle surmounting and detecting device imitating scorpion tail

A technology of scorpion tail and rear tail, which is applied in the field of robot obstacle detection devices, can solve the problems of no retractable ability, large space occupied by the mechanism, and the robot rolls and overturns, etc., to achieve the expansion of body functions, small platform space, and strong passing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

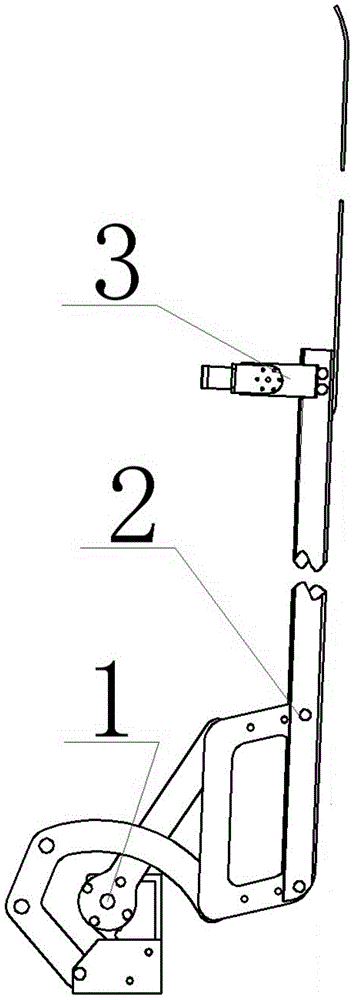

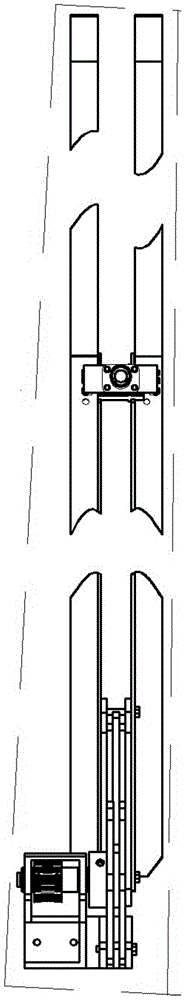

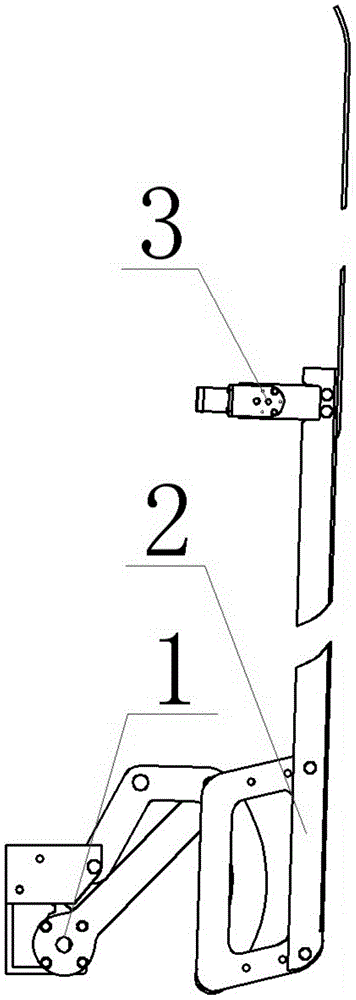

[0013] 1-4, the present invention is a scorpion-tail-like auxiliary obstacle-surmounting and detection device, which is composed of a scorpion-tail retractable mechanism 1, a scorpion-tail-like mechanism 2, and a lens detection mechanism 3. Scorpion tail retractable mechanism 1 is made of fixed base 1-1, worm gear 1-2, driving rod 1-3, driven rod 1-4, driven rod base 1-5, driven rod shaft 1-6, Turbine shaft 1-7, bearing 1-8 and supporting screws; imitation scorpion tail mechanism 2 adopts symmetrical arrangement, consists of diamond tailstock 2-1a / b, rigid rear tail 2-2a / b, flexible front tail 2-3a / b. pin shaft 2-4 and supporting screws; lens detection mechanism 3 is composed of steering gear 3-1, lens frame 3-2, lens holder 3-3, lens 3-4 and supporting screws.

[0014] The fixed base 1-1 is used for installation with the mobile robot. It adopts a modular design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com