Novel ink-jet printing head

An inkjet print head, inkjet head technology, applied in printing and other directions, can solve problems such as affecting inkjet printing speed, increasing production costs, and easy blocking of inkjet printing heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

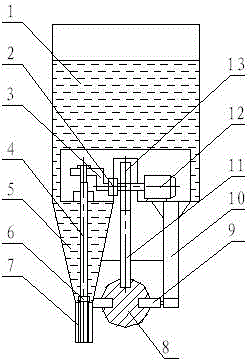

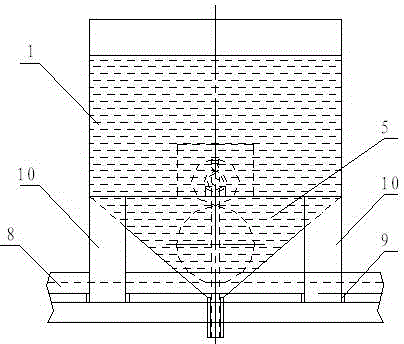

[0011] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0012] Such as figure 1 , figure 2 As shown, a new type of inkjet printing head, including ink cartridge 1, inkjet bucket 5, inkjet head 7, slide rod 4, crankshaft 3, electromagnetic clutch 2, micro motor 12, pinion gear 13, large gear 11, longitudinal rod 8. The bottom of the ink cartridge 1 is connected to the inkjet bucket 5, the inkjet bucket 5 is funnel-shaped, and the bottom end is provided with an inkjet head 7, the inkjet head 7 is a hollow cylinder, and a coaxial slide bar 4 is provided at the middle hollow part , and form a clearance fit with the slide rod 4, the slide rod 4 is provided with a small piston 6 whose size matches the inner diameter of the inkjet head 7. By controlling the position of the slide rod 4 and the small piston 6, the opening of the small piston 6 and the outlet of the ink jet bucket 5 can be precisely controlled, so as to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com