Preparation method for tiamulin micro-capsule preparation

A tiamulin preparation technology, applied in the field of preparation of tiamulin microcapsule preparations, can solve the problems of low bioavailability, poor palatability, strong irritation, etc., and achieve increased feed intake, long-lasting, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

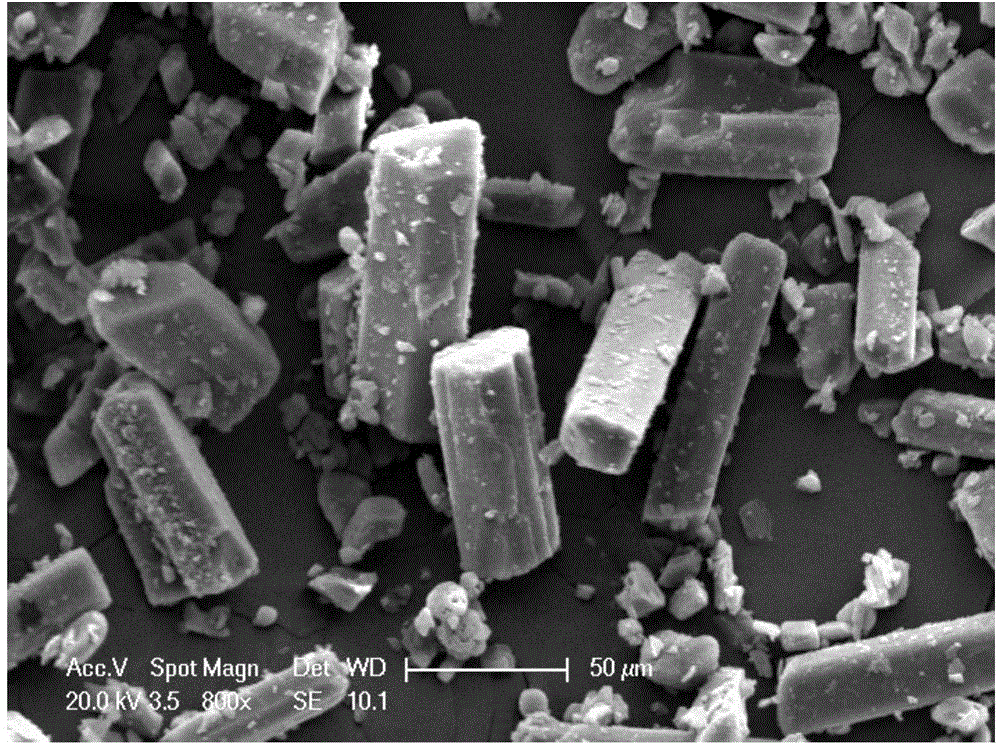

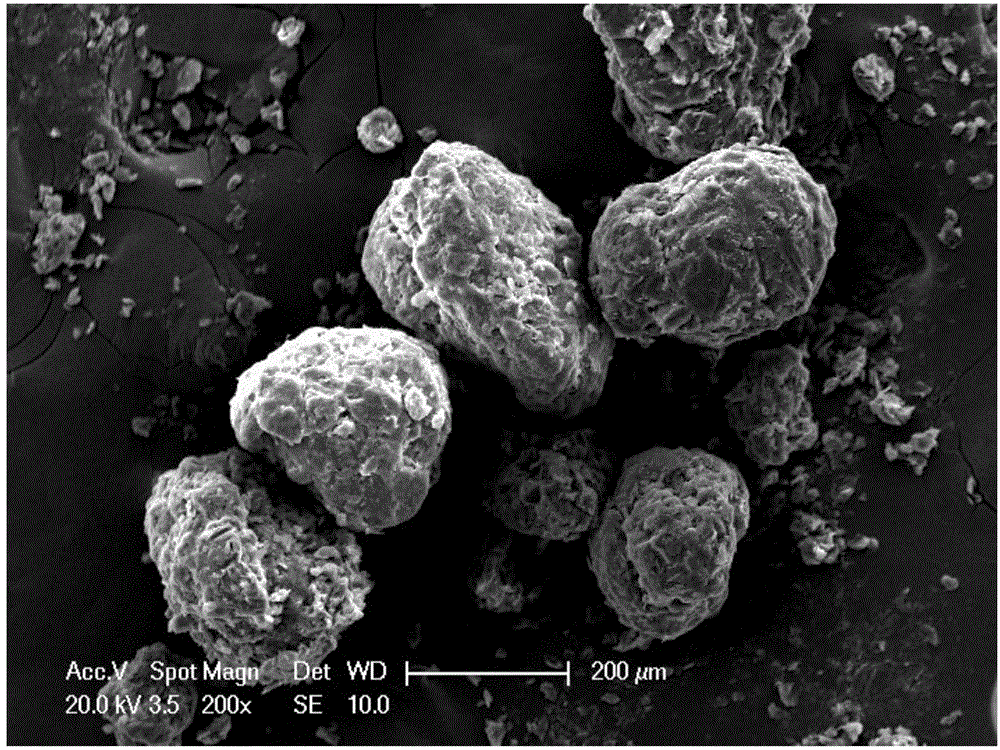

[0026] Add the original tiamulin powder into the hydrogenated vegetable oil containing 5% magnesium stearate and 1.3% triglycerol monostearate in a mass ratio of 1:1, high-speed emulsification and shear stirring for 45 minutes , the temperature is controlled at 80°C; the obtained material is transferred to 4 times the volume of an aqueous solution containing 0.5% chitosan, 0.2% pectin and 1.5% Tween 80 by mass percentage, the temperature is controlled at 80°C, and stirred for 30 minutes After cooling down, keep stirring until the tiamulin microcapsules in the solution are completely precipitated; stop stirring, filter and dehydrate the above-mentioned materials through a 200-mesh sieve, and make tiamulin microcapsule preparations after low-temperature vacuum drying. The particle size of the microcapsules ranges from 150 μm to 250 μm, the recovery rate (the ratio of the total weight of the microcapsules to the total weight of the feed) is 94.4%, and the encapsulation efficiency ...

Embodiment 2

[0028] Add tiamulin original powder into hydrogenated vegetable oil containing 10% magnesium stearate and 1% triglycerol monostearate in mass ratio of 1:8, high-speed emulsification and shear stirring for 15 minutes , the temperature is controlled at 80°C; the obtained material is transferred to 4 times the volume of an aqueous solution containing 0.5% chitosan, 0.2% pectin and 1.5% Tween 80 by mass percentage, the temperature is controlled at 80°C, and stirred for 30 minutes After cooling down, keep stirring until the tiamulin microcapsules in the solution are completely precipitated; stop stirring, filter and dehydrate the above-mentioned materials through a 200-mesh sieve, and make tiamulin microcapsule preparations after low-temperature vacuum drying. The particle size of the microcapsules ranged from 300 μm to 500 μm, the recovery rate was 93.7%, the encapsulation efficiency was 98.7%, and the drug loading was 10.3%.

Embodiment 3

[0030] Add the original tiamulin powder into the hydrogenated vegetable oil containing 2.5% magnesium stearate and 2% triglycerol monostearate in a mass ratio of 2:1, high-speed emulsification and shear stirring for 60 minutes , the temperature is controlled at 70°C; the obtained material is transferred to 4 times the volume of an aqueous solution containing 1% chitosan, 0.2% pectin and 1% Tween 80 in mass percentage, the temperature is controlled at 70°C, and stirred for 30 minutes After cooling down, keep stirring until the tiamulin microcapsules in the solution are completely precipitated; stop stirring, filter and dehydrate the above-mentioned materials through a 200-mesh sieve, and make tiamulin microcapsule preparations after low-temperature vacuum drying. The particle size of the microcapsules ranged from 100 μm to 150 μm, the recovery rate was 96.8%, the encapsulation efficiency was 96.4%, and the drug loading was 63.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com