Intelligent stored cargo space distribution and optimization method

A technology of cargo space allocation and intelligent warehousing, applied in instruments, data processing applications, forecasting, etc., can solve the problem of rarely considering the impact of cargo space allocation on the efficiency of stackers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with drawings and embodiments.

[0059] The present invention mainly comprises the following steps:

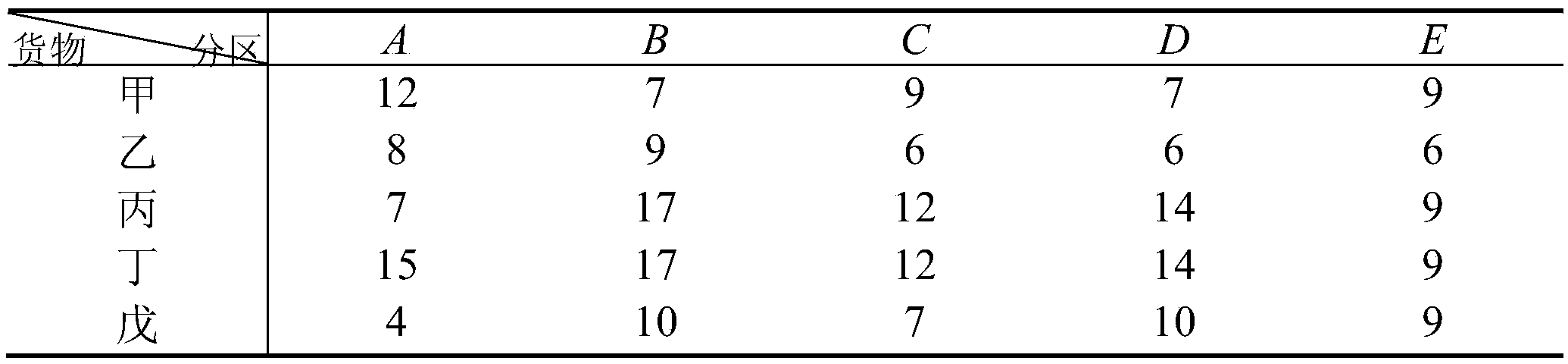

[0060] S1, count the frequency of goods entering and leaving the warehouse and the operating speed of the stacker, and build a mathematical model:

[0061] S11. When partitioning cargo locations, it is assumed that 1) the storage type of goods is known; 2) the quantity of each type of goods stored per unit time is known; 3) the access frequency of each type of goods is known.

[0062] S12, pre-partition: refers to the partition when no goods are stored, and only consider the speed of the stacker when partitioning. That is, if for some cargo locations, the time it takes for the stacker to transport the goods to any one of the batch of cargo locations is the same, then this batch of cargo locations is classified into one category.

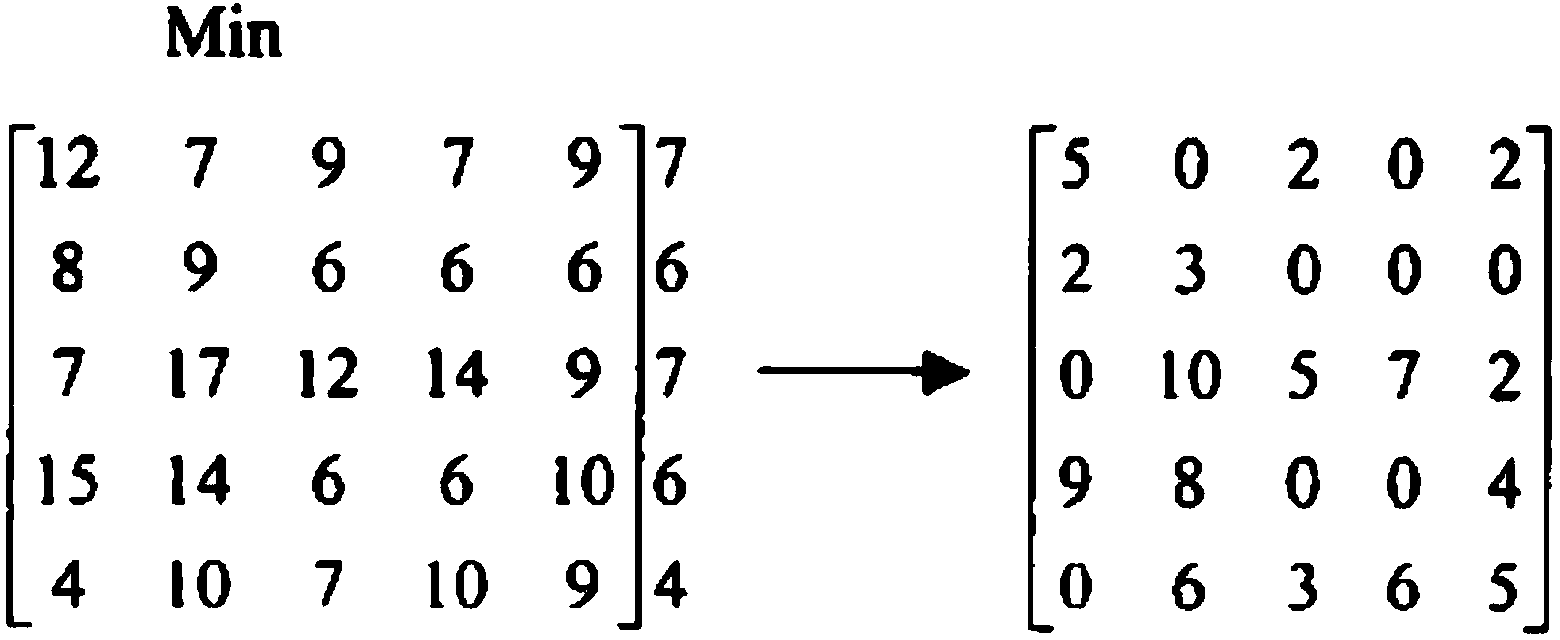

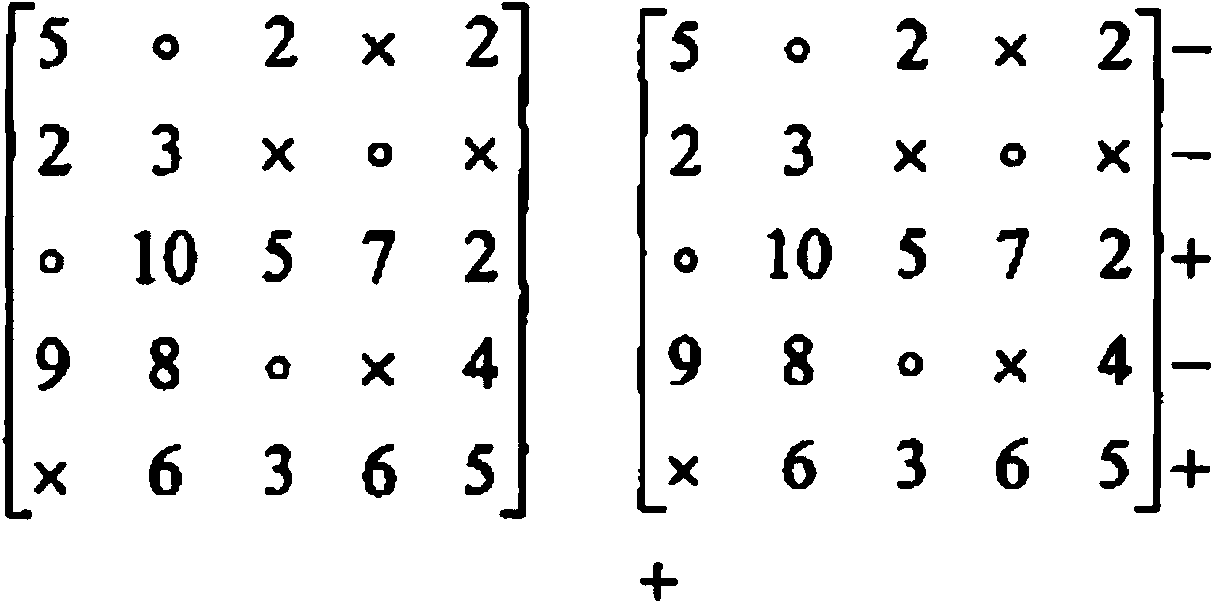

[0063] S13, partition steps and mathematical model:

[0064] S131, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com