Method for detecting discontinuity of nonmetallic material by utilizing eddy current impedance plane detector

A non-metallic material, impedance plane technology, applied in the direction of material magnetic variables, etc., can solve the problems of electromagnetic non-destructive testing method metal material discontinuity detection and other problems, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

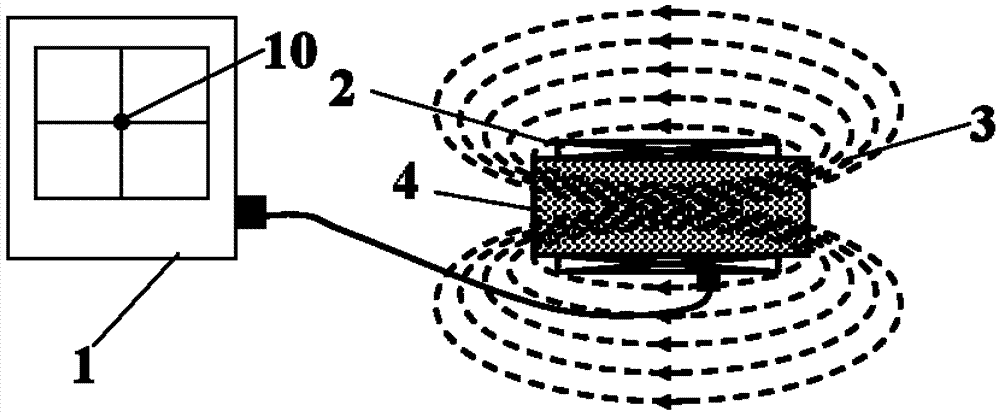

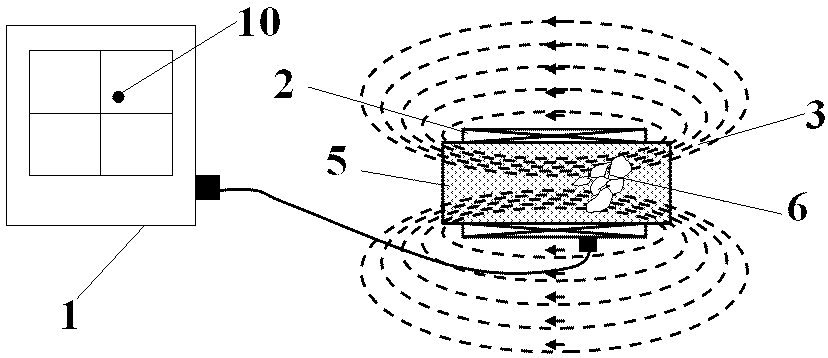

[0017] exist figure 1 , figure 2 In the shown embodiment, the eddy current impedance plane detector is used to detect the discontinuity of non-metallic materials, and the characteristics of the distribution and magnetic induction intensity of the magnetic field 3 caused by the change of the medium in the magnetic field 3 are used, and the eddy current impedance plane detector is used to detect non-metallic materials. Discontinuity in metallic materials; according to the magnetic induction formula = mu 0 mu r , it can be known that the magnetic induction The relative permeability of the medium to the magnetic field mu r related, and the relative permittivity of the medium mu r and relative permittivity ε r Related, when there is a discontinuity in the medium, the relative permittivity of the medium ε r will change, causing the distribution of the magnetic field 3 and the magnetic induction intensity to change, thereby causing the impedance of the detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com