Probe for 3D shape measuring device

A technology for measuring devices and three-dimensional shapes, which can be used in measurement devices, optical devices, and devices to capture or kill insects, etc., and can solve problems such as reduced rigidity, easy vibration, and reduced natural vibration frequency of detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

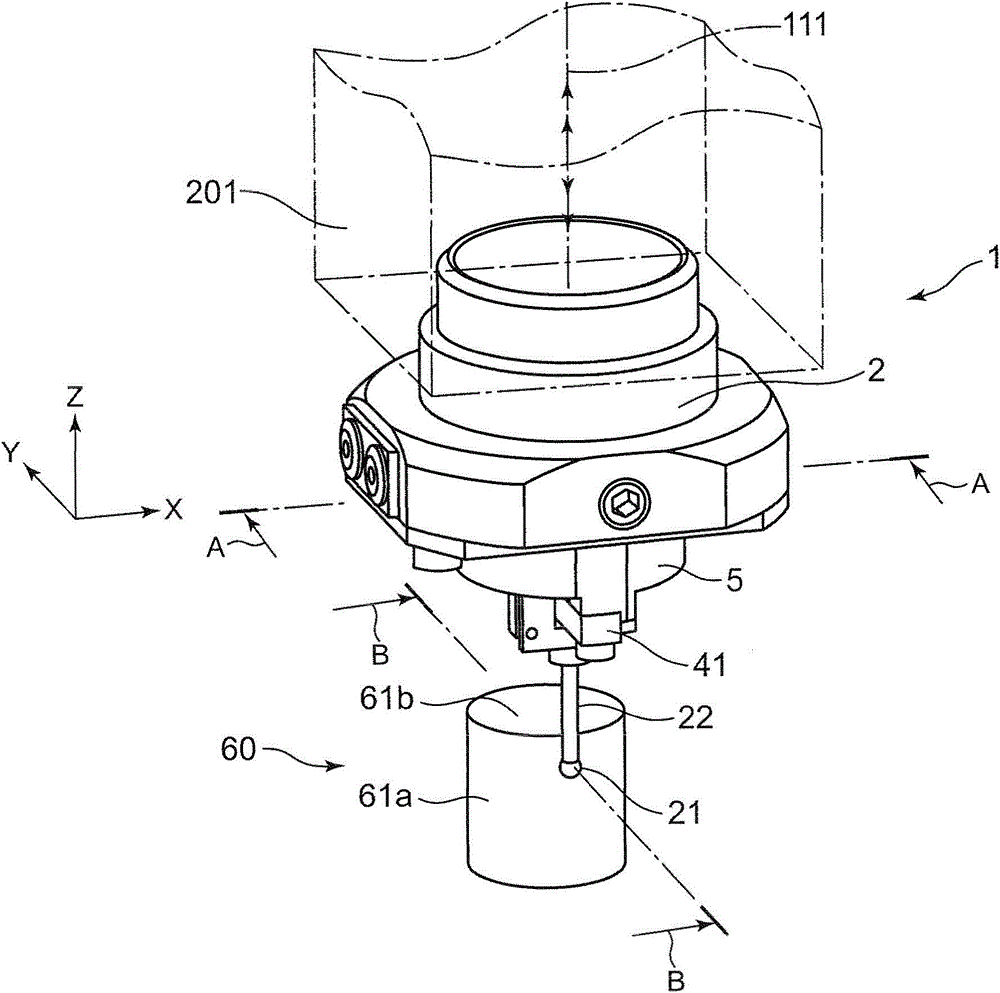

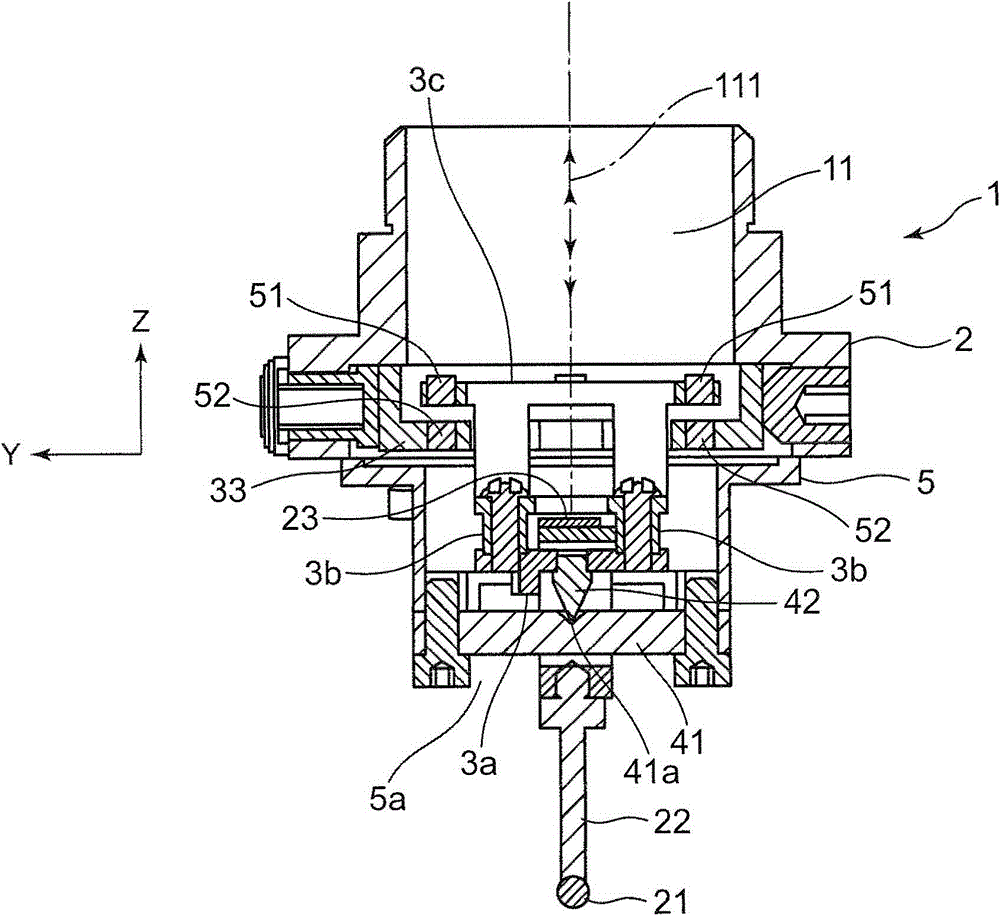

[0042] Hereinafter, a probe for a three-dimensional shape measuring device (hereinafter referred to as probe 1 ) according to an embodiment of the present invention will be described with reference to the drawings.

[0043] First, refer to Figure 1 ~ Figure 4 Probe 1 will be described. figure 1 It is a perspective view showing the appearance of the probe 1 in Embodiment 1 of the present invention. figure 2 will be figure 1 A perspective view showing a part of the detector 1 cut along the A-A plane (XZ plane). image 3 yes figure 1 The cross-sectional view of the B-B plane (YZ plane). Figure 4 is only decomposed figure 1 A perspective view of the movable part in .

[0044] exist figure 1 Among them, the probe 1 is detachably attached to the three-dimensional shape measuring device 201 via the cylindrical attachment portion 2 which is opened at both ends as a whole. The upper end side of the lock member 5 is fixed and attached to the lower portion of the attachme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com