Skid resistance scaffold floor with specially-strengthened structure

A scaffolding and anti-skid technology, applied in the direction of housing structure support, housing structure support, scaffolding accessories, etc., can solve the problems of scaffolding boards slipping and hurting people, affecting the anti-slip effect of scaffolding boards, and scaffolding boards without anti-skid adhesive strips, etc. Achieve the effect of avoiding sand and water accumulation, improving flexural resistance, and avoiding cracks and even fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

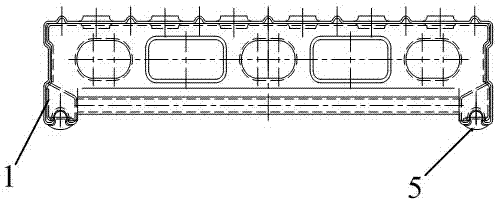

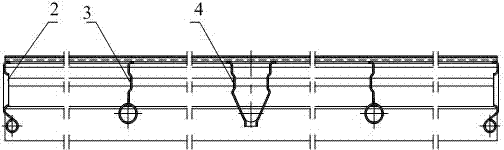

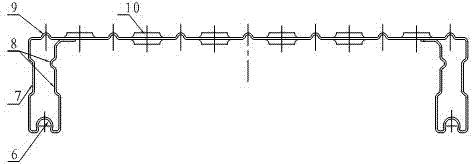

[0018] Such as Figure 1 to Figure 7 As shown, the structure of the present invention especially strengthens the anti-skid scaffold board, which includes the scaffold board main body 1, the end face reinforced sealing plate 2, the first intermediate reinforced support plate 3, the second intermediate reinforced support plate 4, the anti-slip rubber strip 5, and the end face reinforced sealing plate 2 Located on the port of the main body 1 of the scaffolding board, the first intermediate reinforced support plate 3 and the second intermediate reinforced supporting board 4 are located on the main body of the scaffolding board 1, the lower end of the scaffolding board main body 1 is provided with an anti-slip rubber strip 5, and the first intermediate reinforced supporting board 3 A third re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com