Grade-C30 single-particle regenerated self-compaction concrete and preparation method thereof

A self-compacting concrete and single-grain technology, which is applied in the field of building materials, can solve the problems of high raw material costs and complicated procedures, and achieve the effects of simplifying processing procedures, solving environmental and social problems, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

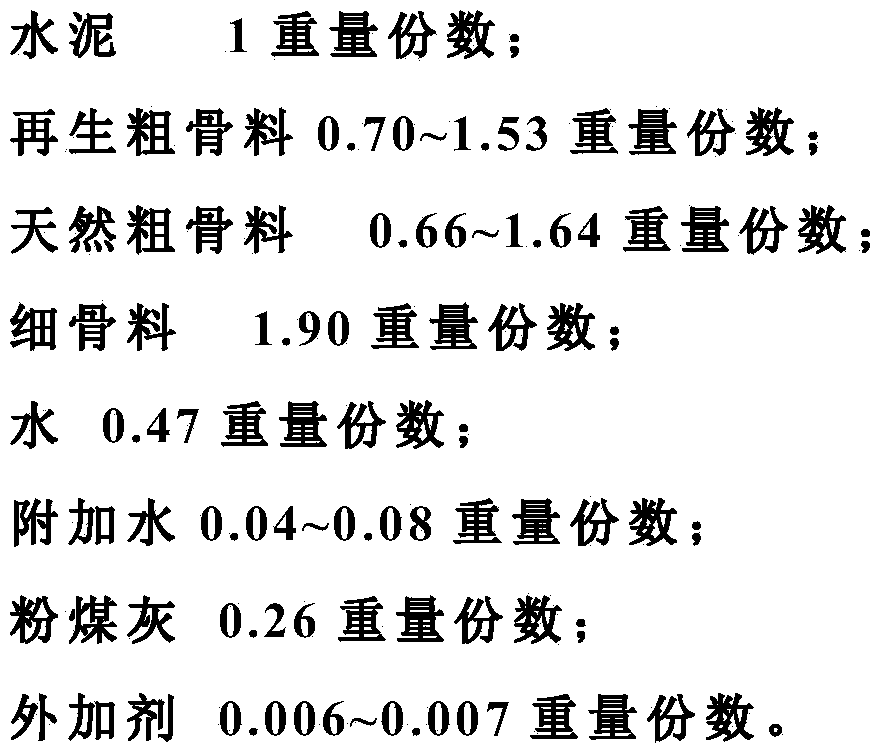

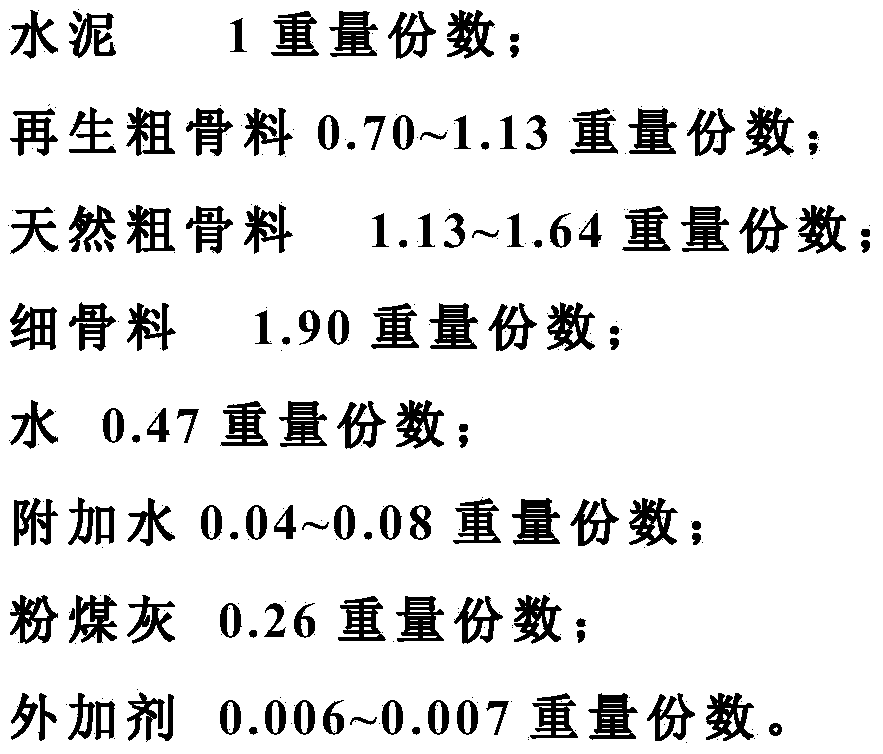

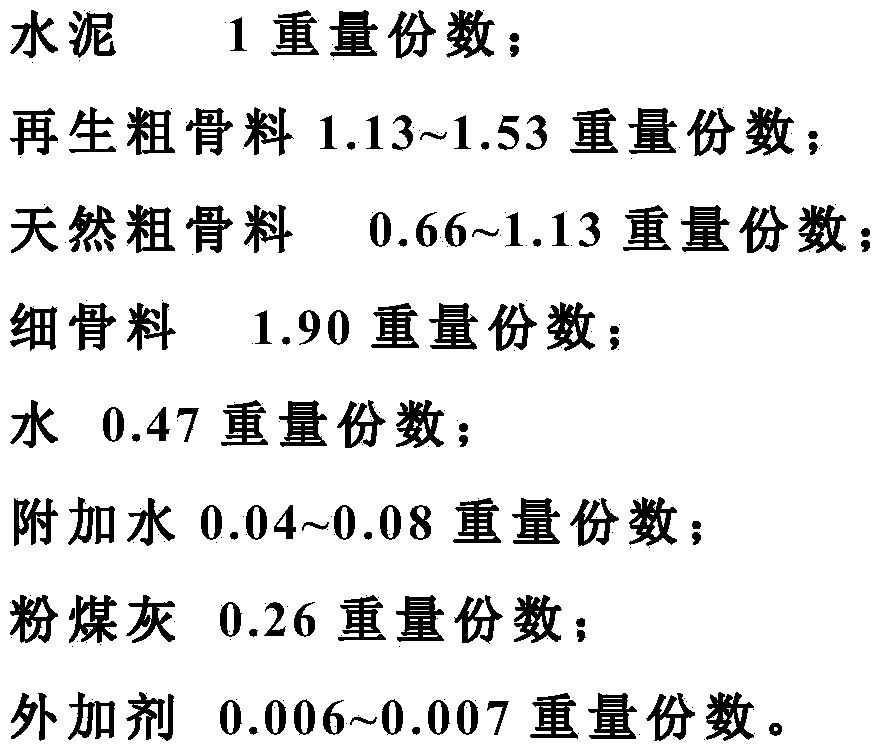

Method used

Image

Examples

Embodiment

[0050] (1) Prepare raw materials:

[0051] Cement: P O42.5 ordinary Portland cement, apparent density is 3.10g / cm 3 .

[0052] Fly ash: Class 1 fly ash, apparent density 2.04g / cm 3 .

[0053] Sand: medium sand with a fineness modulus of 2.36 and an apparent density of 2.65g / cm 3 , bulk density is 1.45g / cm 3 , with a moisture content of 0.4%.

[0054] Natural coarse aggregate: crushed stone with a continuous particle size of 5-20mm, and an apparent density of 2.75g / cm 3 , bulk density is 1.35g / cm 3 , The water absorption rate is 0.45%.

[0055] Regenerated coarse aggregate: After sorting, crushing and screening the waste concrete in construction waste, and sieving out particles smaller than 9.50mm and larger than 20mm, the aggregate particle size is processed into recycled coarse aggregate with a particle size of 10mm to 20mm Aggregate, the apparent density is 2.35g / cm 3 , bulk density is 1.23g / cm 3 , The water absorption rate is 4.76%.

[0056] Admixture: polycarbox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com