Method for synthesizing superfine tungsten trioxide all nanorods by use of hydrothermal process

A technology of tungsten trioxide and hydrothermal method, which is applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of uneven distribution and large diameter of nanorods, and achieve the effect of uniform distribution and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

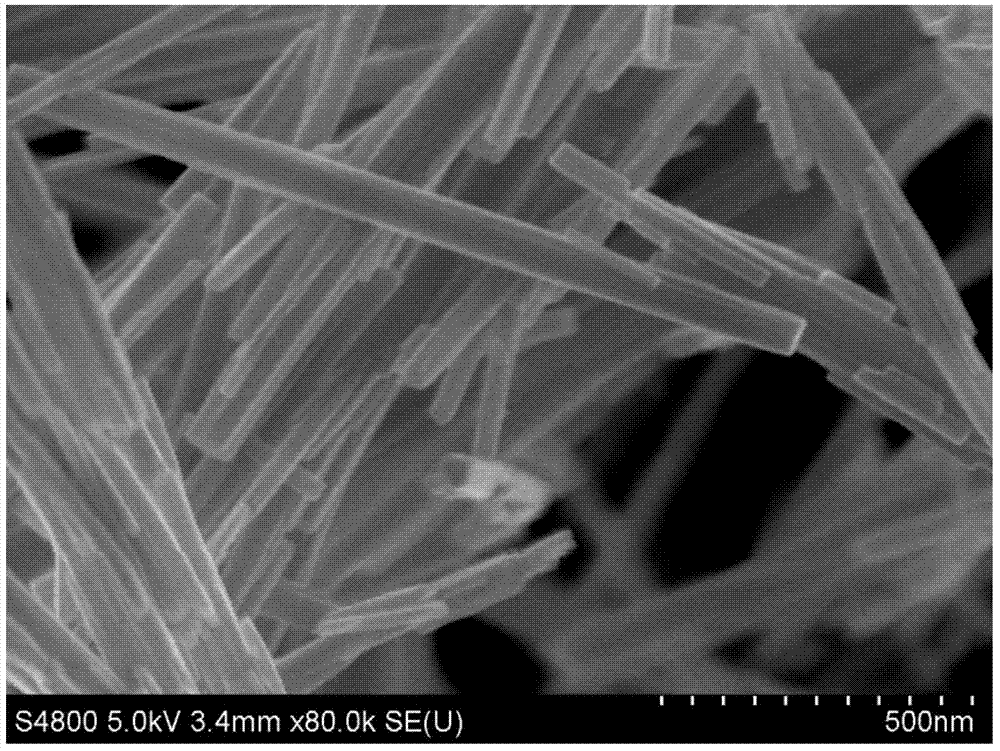

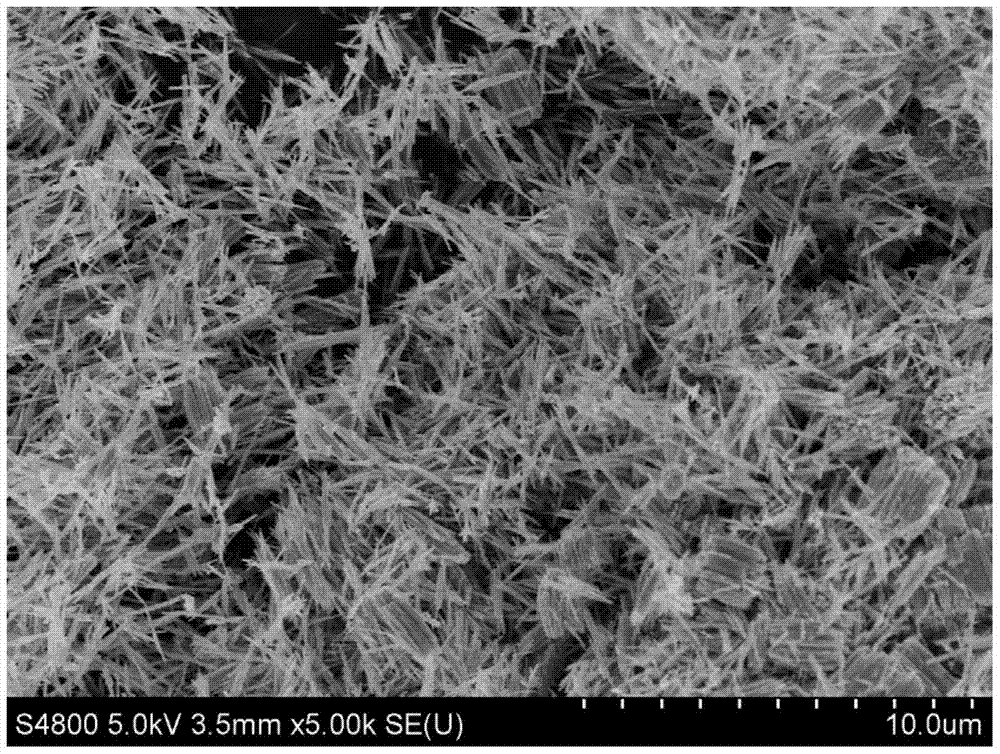

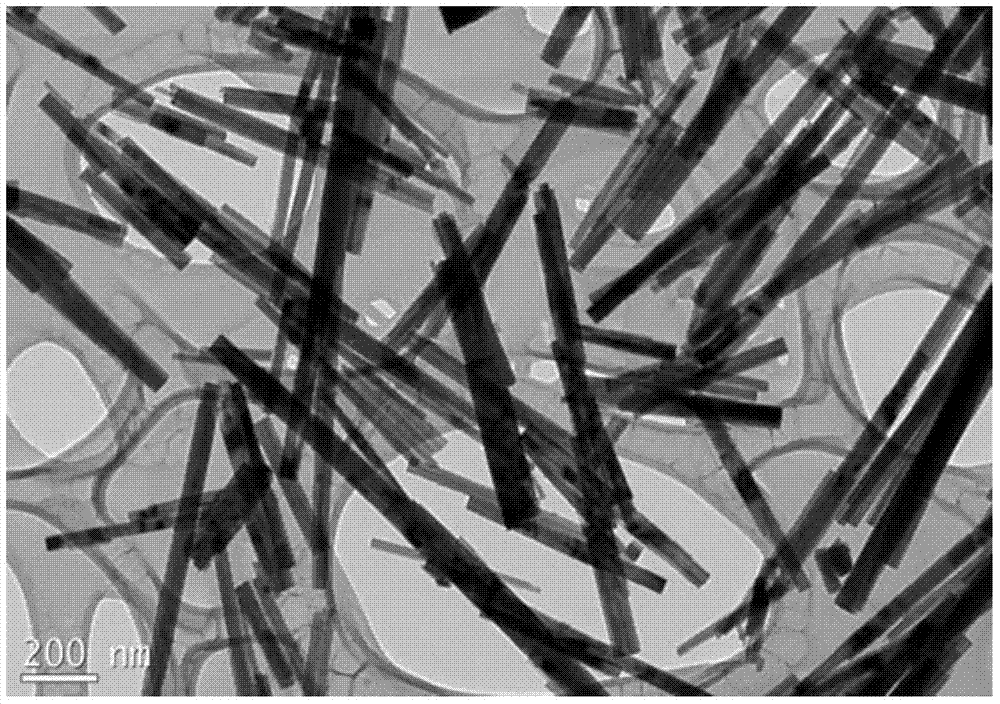

Embodiment 1

[0053] Weigh 9.44g (0.0031mol) of ammonium metatungstate, add 200ml of deionized water to make a solution. Then weigh 15.76g (0.075mol) of citric acid and 25.86g (0.187mol) of sodium sulfate respectively, add them to the above ammonium metatungstate solution, and stir until they are completely dissolved. Keep the molar ratio of the raw materials W element: citric acid: SO 4 2- =1:2:5. Then add hydrochloric acid to adjust the pH value to 1.5, and then place it in a stainless steel reaction kettle with a polytetrafluoroethylene substrate, and react at 180° C. for 24 hours. After taking it out, perform centrifugal cleaning with water and acetone, and finally dry to obtain tungsten trioxide nanopowder. Such as Figure 1 to Figure 4 As shown, analyzed by FESEM, TEM, HRTEM, XRD and other analysis methods, the prepared nanopowder is tungsten trioxide nanorod with a diameter of about 50 nanometers and an average length of 1.5 microns. The ratio of diameter to length is about 1:30...

Embodiment 2

[0055] Weigh 9.44g (0.0031mol) of ammonium metatungstate, add 200ml of deionized water to make a solution. Then weigh 13.4g (0.638mol) of citric acid and 25.86g (0.187mol) of sodium sulfate respectively, add them to the above ammonium metatungstate solution, and stir until they are completely dissolved. Keep the molar ratio of the raw materials W element: citric acid: SO 4 2 - =1:1.7:5. Then add hydrochloric acid to adjust the pH value to 1.2, and then place it in a stainless steel reaction kettle with a polytetrafluoroethylene substrate, and react at 180° C. for 24 hours. After taking it out, perform centrifugal cleaning with water and acetone, and finally dry to obtain tungsten trioxide nanopowder. Such as Figure 6 As shown, the prepared nanopowder is a tungsten trioxide nanorod with a diameter of about 50 nanometers and an average length of 1.5 micrometers. The diameter to length ratio is about 1:30. XRD analysis test results such as Figure 5 Shown, same as embodi...

Embodiment 3

[0057] Weigh 9.44g (0.0031mol) of ammonium metatungstate, add 200ml of deionized water to make a solution. Then weigh 16.55g (0.0783mol) of citric acid and 25.86g (0.187mol) of sodium sulfate respectively, add them to the above ammonium metatungstate solution, and stir until they are completely dissolved. Keep the molar ratio of the raw materials W element: citric acid: SO 4 2- =1:2.1:5. Then add hydrochloric acid to adjust the pH value to 1.8, and then place it in a stainless steel reaction kettle with a polytetrafluoroethylene substrate, and react at 180° C. for 24 hours. After taking it out, perform centrifugal cleaning with water and acetone, and finally dry to obtain tungsten trioxide nanopowder. Such as Figure 7 As shown, the prepared nanopowder is a tungsten trioxide nanorod with a diameter of about 50 nanometers and an average length of 1.5 micrometers. The diameter to length ratio is about 1:30. XRD analysis test results such as Figure 5 Shown, same as embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com