Cleaning method of filter press

A technology for filter presses and cleaning agents, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as clogging of filter plates and filter cloths of filter presses, cumbersome and complicated operations, and time-consuming, so as to reduce labor intensity , Simplify the process, save labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

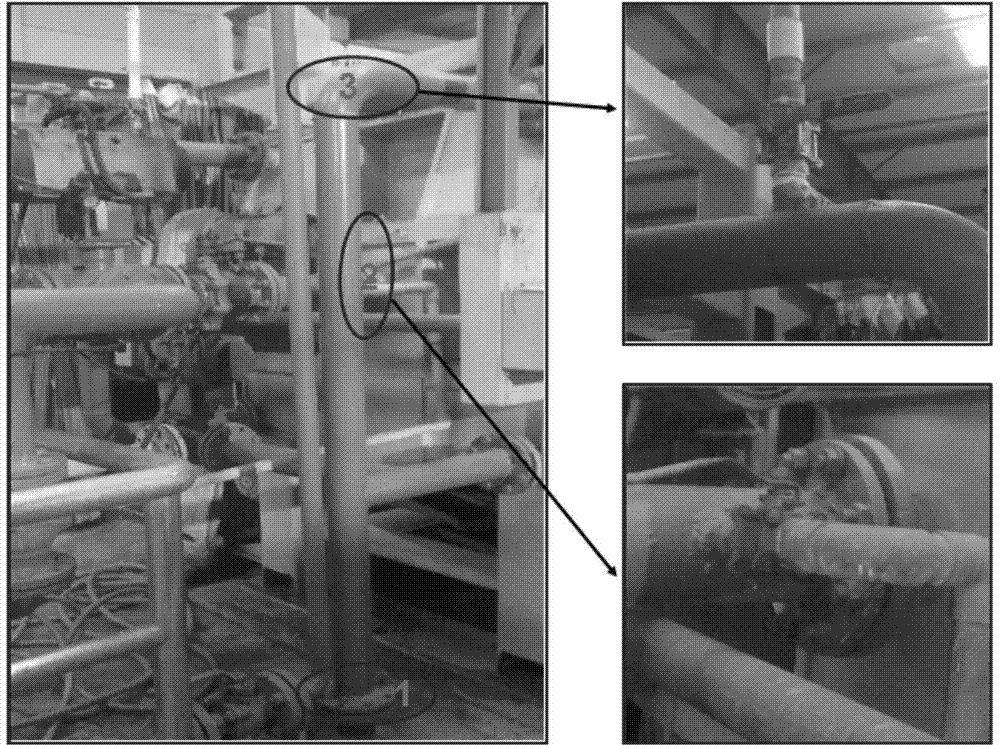

[0020] The application will be further elaborated below in conjunction with the accompanying drawings.

[0021] Guangdong Esquel Textile Co., Ltd. introduced 6 sets of advanced fully automatic flap diaphragm filter presses in 2012. Within one month of operation, the operation was basically stable, the mud cake was well formed, and the mud cake was thick and even in thickness. , The mud cake and filter cloth can be peeled off naturally, and the sludge output is about 70 tons / day. However, after one month, the mud cake gradually became thinner, the thickness was uneven, and the mud cake stuck to the filter cloth. It was necessary to manually use special tools to shovel the mud cake from the filter cloth. The efficiency is reduced, the output of mud pressing is reduced, the manual labor intensity is high, and the automatic high-pressure cleaning device attached to the filter press cannot be cleaned thoroughly.

[0022] The equipment manufacturer provides another cleaning method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com